The highly energy-efficient Circulaire® Hybrid Fume Cupboard from Monmouth Scientific features partial airflow recirculation and environmentally responsible and sustainable active eco-technology.

Hybrid recirculating + ducted fume cupboard technology exhausts clean air to the outside atmosphere and guarantees that, in comparison to a traditional fume cupboard, the volume of exhaust air and the energy utilized are decreased to add up to a greener environment and make it a viable choice for research facilities and laboratories.

- Partial air recirculation: Lower air consumption means up to 60% less outgoing air is generated than a traditional fume cupboard.

- Active ECO technology: The technology helps save energy and operating costs by lowering power output, lighting, and fan speeds without compromising safety.

- Sustainable hybrid technology: By exhausting clean air to the outside atmosphere, recirculating + ducted fume cupboard technology helps reduce emissions.

- Creating clean environments: Operator safety is ensured through filters specified to users’ needs and applications.

Combining safety and sustainability

The Hybrid Fume Cupboard integrates the best features of conventional fume hoods with advanced filtration technology, thereby setting new standards for user safety and environmental responsibility to save on resources, energy, and operating charges.

Environmentally responsible

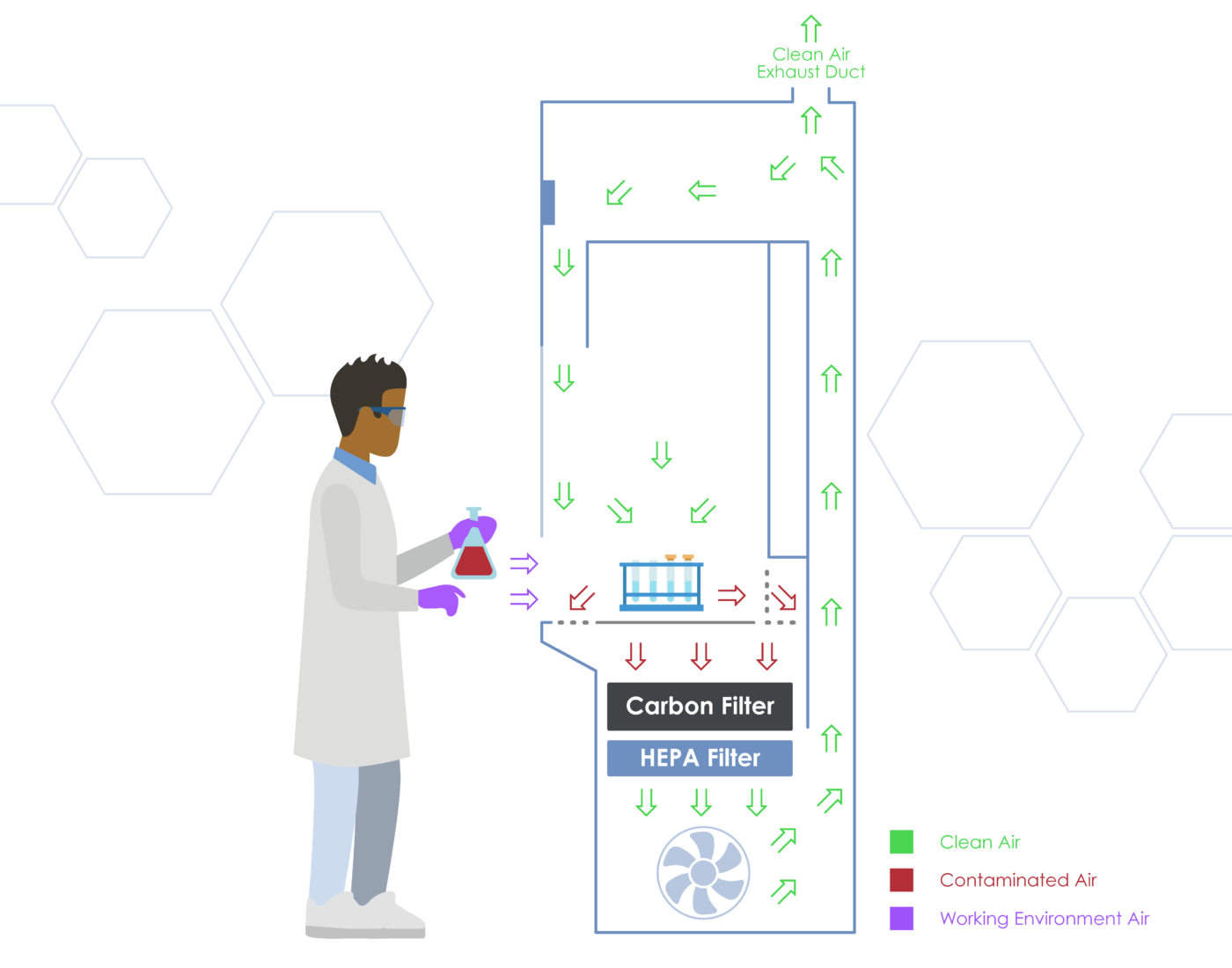

The front aperture draws inflow air in from the laboratory, mixing it with the contaminated air from the working chamber before being pulled down through air intake grilles on the work surface into the Activated Carbon/HEPA Filters*.

The advanced multi-stage filter options allow for superior removal efficiency, meaning that it is applicable in a diverse array of chemical experiments and processes.

Clean and free of contaminants, the airflow is further guided via internal ventilation, where it is divided so that only 40% is pulled to the duct extract system.

The leftover 60% has been recirculated back into the working chamber, making an air curtain throughout the front aperture to offer containment and operator safety. This technique is different from conventional fume cabinets, which depend purely on inflow velocity for safety.

Esentially, this green process results in a 60% decrease in extraction of conditioned laboratory air that would conventially be lost to atmosphere with conventional ducted fume cabinets.

An extra key benefit of the hybrid technology, in comparison to ducted systems, is the extracted air is filtered and clean. The contaminants have been eliminated directly at the source without contaminating the building exhaust air.

The intelligent airflow management technology also helps to maximize air circulation to decrease energy consumption while retaining constant air quality.

Image Credit: Monmouth Scientific Limited

Product specification

Source: Monmouth Scientific Limited

| Model |

HFC 1200 |

HFC 1500 |

HFC 1800 |

| External (W x D x H) |

1203 mm x 942 mm x 2562 mm |

1503 mm x 942 mm x 2562 mm |

1803 mm x 942 mm x 2562 mm |

| Working (W x H) |

90 0mm x 1300 mm |

1200 mm x 1300 mm |

1500 mm x 1300 mm |

| Total Airflow |

389 m3/hour |

488 m3/hour |

578 m3/hour |

| Recirculated Airflow |

189 m3/hour |

288 m3/hour |

338 m3/hour |

| Exhausted Airflow |

200 m3/hour

|

200 m3/hour |

240 m3/hour |

| Filter |

Activated Carbon, H14 HEPA or Carbon-HEPA Combo |

| Power |

230 v |

230 v |

230 v |

| Sound |

Circa. 56 dB |

Circa. 56 dB |

Circa. 55 dB |

Key features and benefits

Active eco-technology

- Hybrid recirculating + ducted fume cupboard technology exhausts clean air to the outside atmosphere, leaving no chemical deposits in the outgoing air ducts.

- It comes with 60% less exhausted air and saves energy and operating charges.

- PIR Sensors ensure effective energy consumption by positioning the cabinet in Eco Mode following a period of operator inactivity.

High-quality filter combinations

Activated Carbon is offered for chemical filtration or HEPA Filters and for particulate - or a combination of both if the application requires.

- Activated carbon filters; ideal for over 500 Chemicals

- HEPA Filters; suitable for particulate, 99.997% efficiency at 0.3µm

Fields of application

The hybrid fume cupboard caters to an extensive range of applications, such as:

- Chemical research and analysis

- Biotechnology and life sciences

- Industrial processes involving detrimental materials

- Pharmaceutical research and manufacturing

Touchscreen control interface

The Visionaire® technology built into the hybrid workstations enables the highest level of operator monitoring, thereby allowing users to control every essential aspect of product operation.

Additional options

- Glass or plastic work surface (stainless steel as standard)

- Electrical outlets

- Gas and water supplies

- SafeChange filter system

Image Credit: Monmouth Scientific Limited