QuattroflowTM has solved the common challenges associated with laboratory space requirements with its newly developed space-saving QF1200CV (Compact Version) Quaternary (Four-Piston) Diaphragm Pump.

The design of the QF1200CV is closely related to Quattroflow’s QF1200 pump; however, the QF1200CV has integrated the pump chamber, pump drive, motor and control box into a single unit.

By eliminating the need for a separate control box to house these components, the QF1200CV exhibits a more compact design to reduce space requirements. As a result, this space-saving pump is an ideal solution for laboratory applications that require a smaller pump model without compromising on flow capacity.

Product Benefits

- Single power cable allows for easy “Plug and Pump” installation and startup

- A wider range of flow rates as compared to the standard QF1200 model

- Single-phase 230V motor

- Available in both Multiple-Use or Single-Use options

- Single-Use models can be comprised of either machined polypropylene (PP) or injection-molded polyethylene (PE) materials

- Multiple-Use models come with Clean-In-Place/Steaming-In-Place (CIP/SIP) and autoclavability properties

- Autoclavability is also available for PP Single-Use models

- Suitable for tabletop applications

Product Applications

Due to the cooperation with customers throughout the development and manufacturing of products, the QuattroflowTM Quaternary (Four-Piston) Diaphragm Pumps have been specifically designed for critical applications in both the pharmaceutical and biotechnology industries.

The mechanism behind the Quattroflow pumps ensures that they maintain minimal impact to samples by gently, safely and securely conveying aqueous solutions and biological products that are typically sensitive to shear force.

By eliminating a mechanical shaft seal and wetted rotating parts, the four-piston design ensures complete product containment without risking potential abrasion or particle generation during its use.

The working principle behind the four-piston pumping principle enables risk-free dry-running, low pulsation, and self-priming.

Product Variations

- Multiple-Use: The Quattroflow stainless-steel Multiple-Use pumps ensure that researchers acquire samples of the highest level of purity, all the while maintaining impeccable containment and cleanability throughout biopharmaceutical-manufacturing operations, ranging from simple product transfer to critical and demanding filtration and chromatography applications. With the added benefit of autoclavability, these pumps are ideal for clean-in-place/steaming-in-place (CIP/SIP) operations.

- Single-Use: The Quattroflow-machined PP and injection-molded PE Single-Use pumps are equipped with a plastic wetted pump chamber that can be replaced as a complete unit as needed by the user. With the option to dispose the used pump chamber and quickly replace it, users can save a considerable amount of time and money without having to clean, sterilize and perform complex cleaning-validation of the pump chamber. This reduction in time restraints allows for a quicker production process to be achieved, all the while maintaining exceptional product purity and sterility through the elimination of any potentially expensive cross-batch or cross-product contamination.

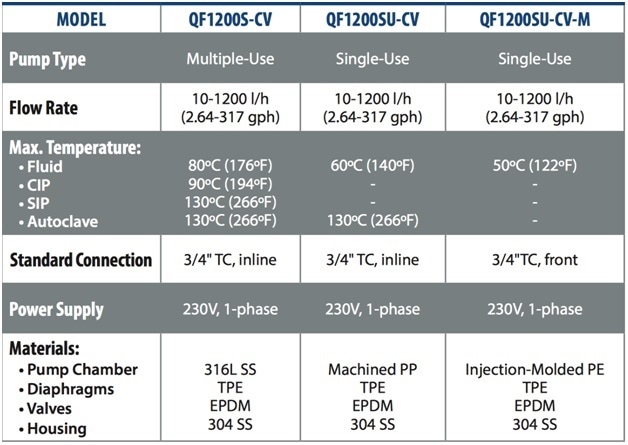

Technical Data