GTx’s scalable electroporation technology is clinically verified and can handle even the most demanding cellular engineering requirements, from product development to translation into clinical trials.

Highlights

- Rapidly develop with a known regulatory route backed by an FDA Master File

- Manufacture confidently with closed, cGMP-compliant, ISO-certified, and CE-marked products

- Move forward with 21 CFR Part 11-enabled software

- Enjoy the proprietary Flow Electroporation® technology from MaxCyte

- Transfect cells quickly from 75 thousand to 20 billion cells

Product features

- Integrated touch screen

- Effortless operation at the touch of a finger

- Enhanced software user interface

- Save time with updated software that offers more functionality and intuitive usage

- Reduced footprint

- Bench-scale, modular equipment

- LED status indicators

- With six vibrant and clearly defined status modes, users have immediate access to the instrument and run status

- Elegant design

- Experience a modern, sleek look that fits into any high-tech lab space

- Barcode reader

- Record crucial sample processing information and reduce manual data entry

- Network capable

- Produce and save run reports automatically onto a shared local disc

- Retractable bag hooks

- When processing high volumes, use convenient hooks and then fold them away when not in use

MaxCyte® offers more than just an instrument; the customer becomes a partner with a cell engineering specialist with the skills to assist users at every level of their research journey.

Image Credit: MaxCyte, Inc.

Compatible consumables and accessories

Supporting products

G-1000

With as few as 400 uL, up to 1 mL, and 2×106 to 2×108 cells, it is possible to clinically produce the therapeutic end product.

Features

- Made from inert, medical-grade materials to safeguard priceless cells

- Well designed for efficient loading and unloading of cells

- Improved design for enhanced handling

- Locking lid to secure sample

Image Credit: MaxCyte, Inc.

Closed buffer

Streamlined, sterile buffer exchange for automated cell concentration saves time.

Features

- 500 mL and 1 L bag options

- Compatible with closed process

- Connection flexibility

- Adaptable to cell concentration and buffer exchange processes

Image Credit: MaxCyte, Inc.

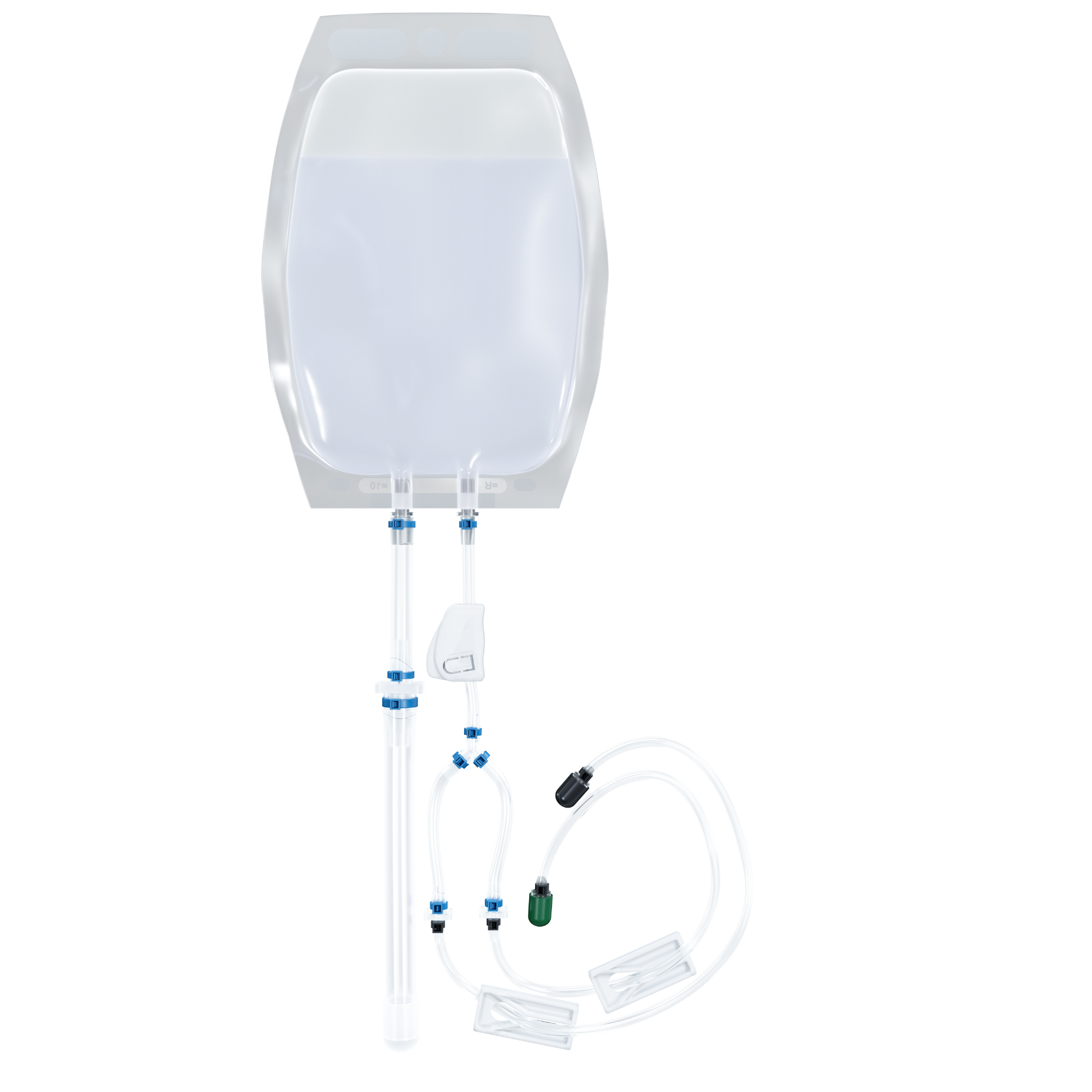

CL-2 GMP

This Flow Electroporation-enabled processing assembly allows users to clinically generate the therapeutic product up to a 100 mL working volume.

Features

- Closed systems and biowelding compatible

- Flow Electroporation permits the processing of up to 20 billion cells in 30 minutes

- Made of high-grade and inert material to safeguard previous cells

Image Credit: MaxCyte, Inc.

P×5 workflow rack

It supports, loads, manages, and transports up to five small processing units in a simple and secure way.

Features

- Durable, stackable, low footprint

- Withstands common lab disinfectants

- “To Do” and “Done” positions for tracking PA workflow status

- Contains 1 to 5 small volume PAs (≤1 ml)

Image Credit: MaxCyte, Inc.

Research applications

Cell therapy

Discover scalable engineering to allow safe and effective cell therapies.

Antibody and protein production

Transient expression for gram-scale protein synthesis can hasten the development of biotherapeutics.

Gene editing

Overcome the challenges associated with genome engineering with highly efficient delivery.