Ceramic components are used in medical devices that demand reliability in various aspects. They are employed in diagnostic imaging equipment parts that require insulation against high voltages, and in surgical instrument parts that require insulation, strength, and heat resistance.

Sapphire tubes

Kyocera Fine Ceramics has manufacturing capabilities to create one-sided sealing, irregular shapes, and hole processing.

High-purity single-crystal sapphire, devoid of voids and grain boundaries, provides superior mechanical characteristics and chemical stability over polycrystalline alumina. Sapphire tubes have good chemical and plasma resistance. These characterisctics can minimize particles, so sapphire is often employed in semiconductor production equipment parts. Sapphire ceramic components also are used in circumstances where optical transparency and heat resistance are necessary.

Kyocera’s sapphire tubes are formed in a tube shape, which reduces post-growth processing time and costs.

Image Credit: Kyocera International, Inc.

Sapphire rod

Sapphire rods are extremely strong, heat-resistant, and corrosion-resistant. Kyocera provides polishing, step processing, and metal fitting assembly.

Single crystal sapphire, a high-performance material with excellent strength, heat resistance, and corrosion resistance, is formed into a rod shape.

By incorporating applied technologies such as stepped processing and metal fitting assembly into the excellent surface polishing technology that Kyocera has developed over the last 50 years through its single crystal sapphire manufacturing business, the range of applications is expanding as parts for semiconductor manufacturing equipment and analytical instruments that demand high precision and durability.

Image Credit: Kyocera International, Inc.

Stator

Fine Ceramic stators have excellent chemical and wear resistance.

Concerning size, Kyocera can dispense ultra-small and fixed volumes to production. Kyocera offers highly reliable parts by leveraging the numerous benefits of fine ceramics (wear resistance, chemical resistance, chemical stability, minimal thermal expansion, and so on).

Image Credit: Kyocera International, Inc.

Cylinder and piston

Ceramic cylinders and pistons have good chemical and wear resistance.

Kyocera can provide extremely dependable components in ultra-small, fixed quantities by utilizing the numerous benefits of fine ceramics, such as chemical stability, wear resistance, chemical resistance, and low thermal expansion.

Image Credit: Kyocera International, Inc.

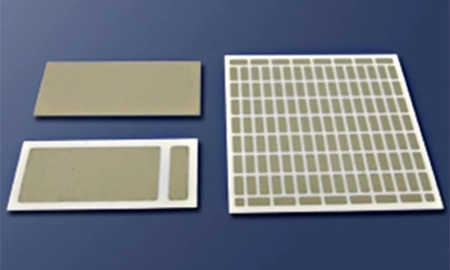

Metallized substrate

A biocompatible ceramic substrate supports the drug delivery system.

Kyocera’s unique Fine Ceramic materials, metallization technology, and vast expertise allows ability to mass manufacture products with excellent thick-film printing accuracy and consistent quality.

Image Credit: Kyocera International, Inc.