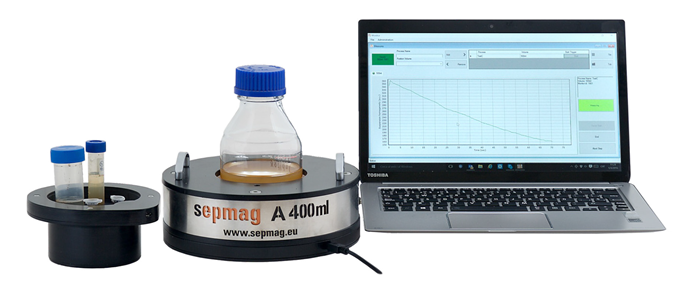

Sepmag® A is a magnetic bead separation system that handles various sample sizes, from microtubes to 400 ml.

Monitor in real-time

The MONITOR software and hardware detect optical changes in the suspension, showcasing its behavior and comparing various compositions.

Well-defined magnetic separation conditions

The entire sample is subjected to a well-defined magnetic force, so variations are limited to the properties of the suspension (particles, buffer).

Full scalability

Its precise separation parameters ensure a smooth transition to higher volumes or production. Just use the Sepmag separator in a larger vessel.

Safe system

Large magnets may be harmful. The systems are made to work close to computers without endangering users.

Image Credit: Sepmag

sepmag® A, change the suspension and monitor the effects

The reproducible technology that ensures constant magnetophysical conditions inside the system ring is leveraged by the sepmag® A scale-up systems. When processes are optimized or sample volumes vary, users frequently work with a wide range of volumes, starting with small tubes and increasing sample size as needed.

Users of sepmag® A systems can begin working with 1.5 ml microtubes and increase the volume to 200 ml (A200 ml) or 400 ml (A400 ml). Each system has a standard holder for various tubes, but users can request adaptors customized to meet their specific needs.

The MONITOR hardware and software records and monitors processes, enabling the operator to investigate how bead size, distribution, concentration, and buffer conditions affect the separation process.

Image Credit: Sepmag

Characteristics

Source: Sepmag

| |

Dimensions and weight |

Caution distances |

| Model |

ø int |

ø ext |

H |

Weight |

ø |

H |

sepmag A200 ml, optimized for 250 ml bottles

For small tubes (1.5-50 ml), when using adaptors |

80

mm |

176

mm |

67

mm |

4.2

Kg |

315

mm |

250

mm |

sepmag A400 ml, optimized for 500 ml bottles

For small tubes (1.5-50 ml), when using adaptors |

96

mm |

206

mm |

67

mm |

5.7

Kg |

340

mm |

262

mm |

Adaptor

- MA022: 2 × 15 ml centrifuge tubes, 2 × 50 ml centrifuge tubes

- MA211: 2 × 2 ml centrifuge tubes, 1 × 15 ml centrifuge tube, 1 × 50 m, centrifuge tube.

- MA400: 4 × 2 ml centrifuge tubes.

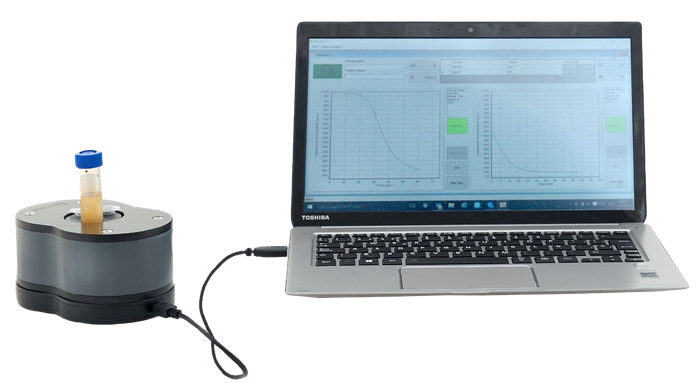

Monitor the biomagnetic separation process

Image Credit: Sepmag

Systems for R&D and small volumes

Users can adjust the suspension and monitor the results for separation at variable volumes under thorough process monitoring.

Sepmag A

Small tubes using MA adaptors and bottles up to 500 ml are ideal for scaling up experiments, process validations, or even small-batch productions.

Benefits

- Explore, monitor, and obtain data on the process

- Easy comparison between processes and runs

- Full recovery of material

- Easy scalability

- Work with viscous liquids and small particles

- Safe

SEPMAG MONITOR (R&D software)

SEPMAG MONITOR (R&D software)

Video Credit: Sepmag

Sepmag LAB

Small tubes with different geometries using MLAB adaptors

Image Credit: Sepmag

Thanks to magnetic separation, filtration, centrifugation, and separation techniques can be replaced with a fast, effective, and clean process. With the least amount of stray fields, SEPMAG®'s exclusive technology produces consistent magnetic force patterns at its large bore in laboratories. This method can handle varying volumes, operates under well-defined magnetic separation conditions, and produces no aggregation problems.

With its powerful separation force and simple re-suspension, the SEPMAG® LAB series is ideal for viscous media and/or tiny magnetic beads or particles. It is available in volumes ranging from 1 to 50 ml.

The operator can investigate how bead size, concentration, or buffer conditions affect the separation process by recording and monitoring processes using the MONITOR hardware and software.