A team for the University of Campinas (UNICAMP), has tailored tantalum oxide (TaxOy) films onto commercially pure titanium (cpTi) surface in the efforts of producing a biocompatible surface treatment optimized for titanium-based implants.

Image Credit: MarinaGrigorivna / Shutterstock.com

Image Credit: MarinaGrigorivna / Shutterstock.com

The team developed two surface types; amorphous or crystalline by a process called sputtering. The efficacy of thee surfaces wasted determined by testing the impact of TaxOy films on the adhesion of the bacterium Streptococcus sanguinis. X-ray diffraction analysis revealed the empirical nature of the titanium oxide - β-Ta2O5 phase. With increasing oxygen deposition, the films demonstrated high optical homogeneity.

The crystalline β-Ta2O5 coating was improved and subsequently biocompatible compared with commercially pure Titanium. Neither the amorphous or crystalline tantalum oxide films did not increase bacterial adhesion. As such, the β-Ta2O5 coating improved titanium surface properties and positively affected cell spreading and morphology.

Commercially pure Titanium (cpTi) is used readily in dental implants owing to its successful biocompatibility integration with the surrounding bone tissue and resistance to corrosion. However, Ti and alloys do not possess bioactive properties and tend to bond mechanically rather than chemically with bone.

The results in fracturing and loosening: an issue that the team sought to overcome by Tantalum (Ta) filming. Ta is, in contrast to Ti, highly bioactive and bonds chemically with bone to optimize the process of osseointegration. Together with its corrosion resistance, blood compatibility, and opacity to X-ray radiation, this makes it a promising metal for use in biomedical implants.

However, it is limited due to its high density, high melting point, and manufacturing costs. By applying a layer of Ta oxide film as a coating onto a Ti surface, the good properties of both Ti and Ta are combined to produce an excellent-quality implant material

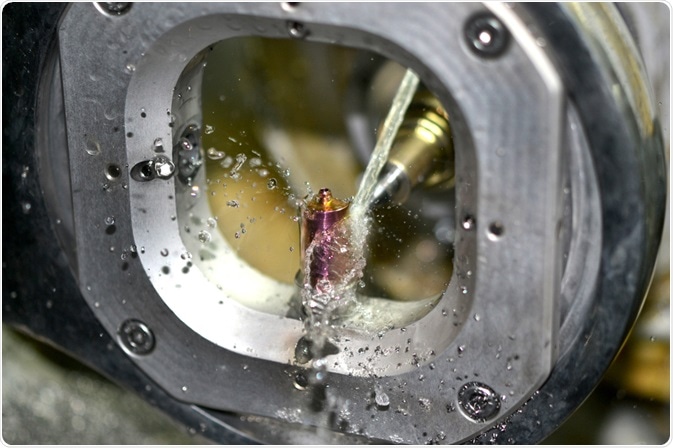

Techniques previously used for Ta and TaxOy thin film deposition onto substrates have included: electrochemical deposition, laser processing, liquid phase deposition, metal-organic decomposition, plasma immersion, ion implantation, chemical vapor deposition, sol-gel, and magnetron sputtering.

Of these techniques, magnetron sputtering is the most promising, as it can produce uniform film growth over very large areas. Optimizing the properties of the film can be determined by the sputtering pressure, plasma power, reactive atmosphere (Ar and O2), and temperature. The most desirable phase of tantalum oxide is the crystalline β-Ta2O5, as this demonstrates biocompatibility.

The porous phase is known to reduce Streptococcus aureus and Actinobacillus actinomycetemcomitans adhesion. However, obtaining this phase is challenging, and research is necessary to understand how the formation and properties of the TaxOy film deposited by magnetron sputtering occur.

In answer to this knowledge gap, the team addressed four points:

1. Tailoring the synthesis of Ta-based thin films onto a cpTi surface by magnetron sputtering technique

All O2 flow measurements used demonstrated high optical homogeneity of the film which indicated homogeneity in both thickness and refractive index

2. Characterization of the physical and chemical properties of Ta-based films

The Ta-treated groups presented tantalum (Ta), oxygen (O), and Titanium (Ti) in the chemical composition.

3. Determine the impact of Ta-based films on initial Streptococcus sanguinis adhesion

The team reported the interaction between S. sanguinis and different TaxOy films deposited onto the cpTi surface; they found that all flow measurement treated surfaces did not promote bacterial adhesion, which prevents biofilm-related diseases such as peri-implantitis and the failure of implant treatment.

4. Observing the morphology and spreading of pre-osteoblastic (MC3T3-E1) cells on crystalline Ta oxide film.

The team found that the morphology of cells cultured grown on the β-Ta2O5 film differed to the uncoated cpTi. In addition, the adherent cells showed a greater spread, possessing a greater number of filipodia (finger-like projections); this suggests that cells respond better to this surface as filipodia are essential for shape, cell movement, and attachment. As such, β-Ta2O5 film improves cell shape and spreading which prevents microbiological degradation in the mouth

Beline et al. conclude that the results they obtained from this study are preliminary – precluding them from immediate implementation in the lab. To this end, further in vivo and in vitro studies are necessary to investigate the cellular response to the surface treatment.

Source

Beline et al. (2019). Tailoring the synthesis of tantalum-based thin films for biomedical application: Characterization and biological response. Materials Science and Engineering: C. https://doi.org/10.1016/j.msec.2019.03.072.

Further Reading

Last Updated: May 18, 2023