What is Real-Time Release Testing?

The evolution of quality control in pharma manufacturing

Benefits of RTRT for drug safety and efficiency

Technical aspects of implementing RTRT

Regulatory landscape for RTRT

Challenges and considerations in adopting RTRT

Case studies: success stories in RTRT implementation

Conclusion

References

Further reading

Large-scale pharmaceutical manufacturing is a highly complex and multi-faceted field requiring extensive regulation and drug quality assurance. While traditional in-process control (IPC) approaches are a sufficient standard of practice, newer methods like Real-Time Release Testing (RTRT) improve quality assurance and efficiency.1,2

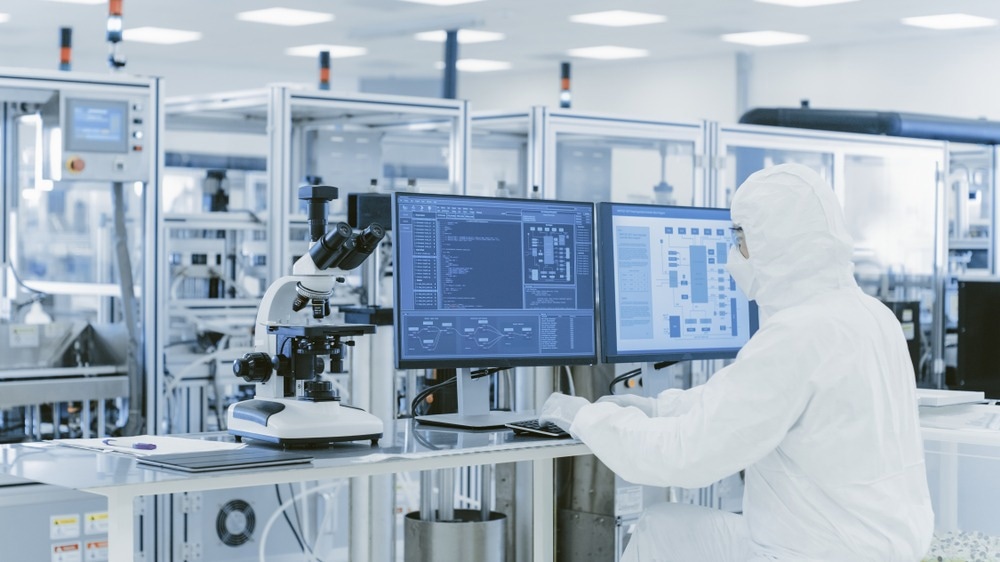

Image Credit: Gorodenkoff/Shutterstock.com

What is Real-Time Release Testing?

Real-Time Release Testing (RTRT) is an advanced approach to biopharmaceutical manufacturing quality control that improves upon current systems. RTRT is defined as the ability to evaluate the quality of a pharmaceutical product using in-process data gathered throughout the manufacturing process.1,2

This is designed to improve upon conventional approaches of off-line end-process testing, which often rely on Statistical Process Control (SPC).3 SPC is traditionally used to identify and eliminate sources of variability in the manufacturing process using quality inspections of post-manufacturing end products.3

The evolution of quality control in pharma manufacturing

The traditional standard of practice across pharmaceutical manufacturing, SPC, operates within pre-established process conditions to monitor general production and assess the quality of completed batches.3 These approaches contain blind spots, the most significant of which is the inability to assess products at intermediate steps.3

By 2011, Continuous Process Verification (CPV) had been introduced by the International Council for Harmonization (ICH) as an alternative to SPC.3 Within CPV operations, performance and quality are evaluated continuously throughout the entire pipeline, providing more thorough information and improving statistical confidence.3

The introduction of quality assurance at stages before the endpoint opened the door for other real-time methods, including Process Analytical Technology (PAT) tools and, eventually, fully realized RTRT.1-3

Benefits of RTRT for drug safety and efficiency

The ability to monitor manufacturing processes at intermediate stages is beneficial in several ways. High frequency of sampling consistently quantifies inter- and intra-batch variability and improves process flexibility.2 Operations become more adaptable, with real-time data allowing for fine-tuning of process parameters and resulting in a more reliable end-product.1-3

Image Credit: Mike Mareen/Shutterstock.com

Increased oversight enables manufacturers to release medications faster and more efficiently by diverting failed materials at intermediate stages rather than discarding a full batch at the process conclusion.1-3

Technical aspects of implementing RTRT

RTRT, in practice, can take many forms, such as PAT tools, which represent the specific instruments used to quantify intermediate quality attributes (IQAs).1,3 The Center for Drug Evaluation and Research (CDER) at the US Food and Drug Administration (FDA) published guidelines on the implementation and operation of PAT tools in 2004, firmly establishing its place in Pharma QA.3

This marked a massive paradigm shift in quality control conventions, with the European Medicines Agency (EMA) and the Ministry of Health, Labor, and Welfare (MHLW) in Japan adopting these guidelines soon after.3

PAT tools are established in literature to improve multiple stages of processing, including blending, granulation, tableting, and coating. Near-infrared spectroscopy (NIRS) is a common tool that uses a fiber optic probe and molecular vibrational motion to measure the quality of an intermediate product.2,3

Integration of RTRT can represent a major challenge requiring a high level of process understanding and an acceptable risk/cost ratio.1,3 In addition to administrative challenges, practical requirements such as the development of reference methods to validate sensors can require a great deal of time and money.2

Regulatory landscape for RTRT

The regulatory landscape of RTRT tends to be more complex than traditional analytical testing and is actively evolving as these methods are integrated into industry standards.

Spearheaded by the FDA, EMA, and Pharmaceuticals and Medical Devices Agency (PMDA), guidelines supporting the long-term use of PAT and RTRT have been published.2 For example, the EMA established a novel notification tool operating on a “do and then tell” model as opposed to a traditional approach requiring prior approval before action. This avoids processing stoppages while approvals are obtained.2

In addition, the FDA’s Emerging Technology Program implements pre-submission or regulatory submissions to an Emerging Technology Team (ETT).2 The main job of the ETT is to provide guidance, answer queries, and occasionally perform Pre-Operational Visits (POV) to facilities, allowing increased regulatory understanding within pharmaceutical companies looking to employ RTRT.2

Challenges and considerations in adopting RTRT

As with any overhaul of highly nuanced and regulated industries, the adoption of RTRT presents many logistical challenges. Steep learning curves require large-scale capability shifts and increases in employees specializing in PAT.2,4

From an operational perspective, these hiring adjustments are required for consistent maintenance and updates required of PAT tools and other sensor equipment.1,2,4 For example, unforeseen variability in raw materials due to changing suppliers can invalidate current models and lead to frequent updates of RTRT systems.1,2

In addition to maintenance, the quantity of data to be analyzed and curated exponentially increases due to the high frequency of sample testing at intermediate junctures.2 This creates more intense needs for systems of data storage and traceability, as well as contributing to the aforementioned alterations in hiring practices.1,2

Case studies: success stories in RTRT implementation

RTRT has already been employed by several large-scale pharmaceutical manufacturers such as Eli Lilly and AstraZeneca.

AstraZeneca developed a system that blended PAT tools, in-process monitoring of stages like tablet hardness, and cGMP practices at various stages of commercial tablet manufacturing.2 This was the first approach of its kind to obtain regulatory approval in 2007 in Europe.2

Eli Lilly contributed to the RTRT sphere through the development of a feed frame spectroscopic PAT tool allowing real-time measurement of active ingredient concentration within a final blend of a pharmaceutical powder.2 Having demonstrated its utility, Eli Lilly’s RTRT feed frame approach was adopted in several markets as part of the conventional control strategy.2

The future of pharmaceutical quality assurance

RTRT is a representation of the evolutionary state of pharmaceutical technology and manufacturing. CPV has a very strong foundation within drug quality assurance with published regulatory frameworks and established stages in the manufacturing process.

Despite this strong foundation, challenges remain, such as the aforementioned logistical stresses, lack of harmony across regulatory establishments, and stages in manufacturing that still require development, such as tablet porosity.2,3

Despite these drawbacks, RTRT has shown a hugely compelling potential to increase the efficiency of product release, decrease waste, and increase process flexibility if companies are willing to take the leap.

Conclusion

RTRT represents an exciting direction for pharmaceutical manufacturing and quality assurance, promising decreased release times, reduced batch waste, and higher levels of statistical confidence.1-4 These improvements offer incentives to company functioning as well as increases in drug availability4.

Despite the logistical efforts that may deter some organizations, RTRT will be a massive improvement to the industry and represents the benefits of continuous innovation challenging the status quo.

References

- Jiang M, Severson KA, Love JC, et al. Opportunities and challenges of real‐time release testing in biopharmaceutical manufacturing. Biotechnology and Bioengineering. 2017;114(11). doi: 10.1002/bit.26383

- Markl D, Warman M, Dumarey M, et al. Review of real-time release testing of pharmaceutical tablets: State-of-the art, challenges and future perspective. International Journal of Pharmaceutics. 2020;582. doi:10.1016/j.ijpharm.2020.119353

- Kim EJ, Kim JH, Kim MS, et al. Process Analytical Technology Tools for Monitoring Pharmaceutical Unit Operations: A Control Strategy for Continuous Process Verification. Pharmaceutics. 2021;13(6). doi:10.3390/pharmaceutics13060919

- Schmidt A, Helgers H, Vetter FL, et al. Digital Twin of mRNA-Based SARS-COVID-19 Vaccine Manufacturing towards Autonomous Operation for Improvements in Speed, Scale, Robustness, Flexibility and Real-Time Release Testing. Processes. 2021;9(5). doi:10.3390/pr9050748

Further Reading

Last Updated: Jun 3, 2024