Continuous manufacturing

On-demand manufacturing

Personalized manufacturing

References

Further reading

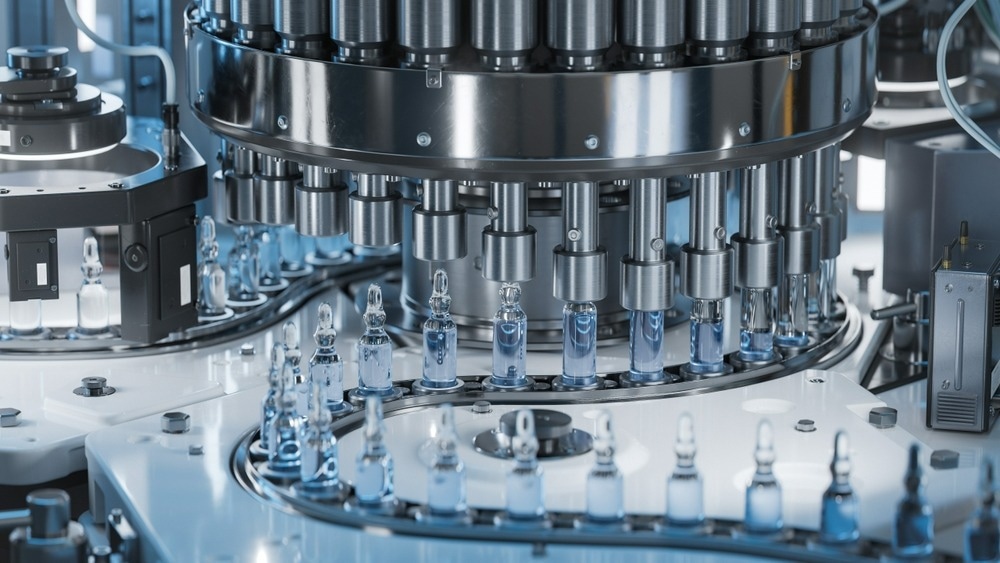

The manufacture of medicines must draw on expertise from a wide range of disciplines, from the initial investigation and design of a new drug or therapeutic to wide-scale production and distribution, also considering the additional quality control measures that must be upheld throughout these stages with regard to pharmaceutical products.

Image Credit: IM Imagery/Shutterstock.com

Continuous manufacturing

Generally, pharmaceutical products are produced in batch processes with multiple discrete steps, often necessitating lengthy storage periods while quality testing is performed or the equipment required is prepared after the previous batch.

Fluctuations in demand are also difficult to respond to using batch production since the batch currently in production must be completed, and scaling up would require larger equipment. Instead, the FDA encourages drug manufacturers to switch toward continuous production processes. Raw materials are fed into a fully integrated assembly line that completes the production of the desired product in a single run, allowing production to be scaled to demand quickly and efficiently manner.

Tracking and tracing of products in the event of a recall may actually be easier during continuous production processes as rather than recalling the entirety of a batch, the scale of which is determined by the size of the equipment utilized, products can be time-stamped with when they left the assembly line, allowing the recall of products at a particular time plus or minus a few minutes.

This type of continuous manufacturing has only been made possible with modern technologies that can ensure continuous detection of quality assurance issues and technical faults. Many other chemical industries have all but made the transition to continuous manufacture where possible.

The enhanced quality assurance standards of pharmaceuticals, as well as high start-up costs, have meant limited adoption of continuous manufacturing in the pharmaceutical industry, but continuous manufacturing processes have been developed for several common drugs such as ibuprofen and tamoxifen, the hormone therapy used to treat breast cancer.

Image Credit: Pavel Chagochkin/Shutterstock.com

Another major advantage of continuous manufacturing processes is that carcinogenic drugs such as this can be produced with minimal human contact, all chemical processes taking place internally without requiring intermediate transfer by staff.

A large majority of drug manufacturing processes require a crystallization step followed by filtration and isolation of the final product, which has presented a significant technological hurdle regarding continuous manufacture.

Crystallization requires a high concentration of product in an appropriate solvent with precise conditions in order to generate crystals of the desired size, allowing them to be efficiently separated by filtration. An equilibrium between dissolved and solid compounds is reached that pushes heavily in favor of crystal production, but this is difficult in continuous systems and results in low yields. To establish equilibrium in closed systems, the concentrated liquid drug is continuously fed into the crystallization chamber while a slurry containing the crystals is constantly removed.

Chaining multiple mixing tanks with differing temperatures and other conditions allows high control of crystal formation mechanisms, and cross-flow filtration is used to ensure that only the desired crystals are allowed to pass to the next chamber.

On-demand manufacturing

The emergence of 3D printing in recent years has allowed the on-demand manufacture of personalized physical pharmaceutical products such as prosthetics, implants, and respirators. 3D printing has also been applied to the rapid production of custom medicines, able to print shaped tablets containing the desired drugs for enhanced dose flexibility and release profile.

The FDA approved the epilepsy drug spritam in 2015, which is manufactured entirely through layer-by-layer 3D printing methods that allow the medicine to break down and be absorbed very quickly upon ingestion compared to traditionally prepared pressed tablets. The main excipients of printed tablets are edible long-chain molecules such as polyethylene glycol, polyvinyl alcohol, or mannose sugars, into which the desired active drug component can be mixed.

The quick turnaround time of batch 3D printing compared to setting up a dedicated facility may have particular clinical applications in early drug development and research as well as in unique and first-response situations, with obvious advantages towards personalized medicine. Unfortunately, the hot extrusion method used to layer the 3D printed material may be damaging to many drug compounds, and numerous other technical challenges remain to be addressed.

Image Credit: ivector/Shutterstock.com

However, the technology is yet in its infancy and will likely become commonplace at all stages of medicines production and distribution. 3D bioprinting of tissue cultures and organs has also become feasible in recent years by laying cells atop one another in a binding extracellular matrix bioink, though it remains in the early tentative stages of research. Like the on-demand printing of medicines, the on-demand production of tissue samples genetically identical to the patient for either testing or implantation may become a reality in the near future.

Personalized manufacturing

Large-scale batch production of medicines is antithetical to the concept of personalized medicine, for which manufacturing techniques such as 3D printing and short-run continuous production may be ideal. As already discussed, specifying dose, drug mixture, release profile, and other physical parameters of a medicine is possible using 3D printing, but personalized medicine extends to highly specific gene targets and DNA-based therapeutics.

For these already existing medicines, pharmaceutical companies utilize “cookie cutter” platforms, from which they can make personalized adjustments on-demand in small batch processes. However, the manufacture of these medicines is currently highly labor-intensive and costly. Thus, the integration of automation and continuous manufacturing into personalized medicine is required.

This may signal a shift in the way medicines are manufactured in the future as intellectual property belonging to the biggest pharmaceutical companies comes off-patent, and it becomes more profitable to operate smaller personalized medicine production facilities.

References

Last Updated: May 3, 2023