May 5 2015

Deben reports on the work of the Microscopy & Histology Core Facility at the University of Aberdeen where a newly installed TEM and camera system have enhanced the services provided to users.

Woolpit, United Kingdom, 5th May 2015: Deben, leading providers of in-situ testing stages together with innovative accessories and components for electron microscopy, report on the work of Microscopy & Histology Core Facility at the University of Aberdeen.

The Microscopy and Histology Facility provide access to assorted technologies to researchers at the University of Aberdeen. One core technique is Transmission Electron Microscopy (TEM) which was recently upgraded with the installation of a new JEOL JEM-1400 plus TEM with AMT camera system from Deben. The current research done using this equipment is varied and includes samples such as bone cells, yeast cells and macrophages. Some of the strangest samples recently to pass through the lab include seaweed and sea water plankton. The facility is managed by Kevin Mackenzie.

The TEM allows users to survey their samples at low magnification (down to x10) to easily search for the region of interest. Images are captured using an AMT XR16 ActiveVu camera system. This bottom mounted high sensitivity cooled 4K camera has a very wide angle field of view, ideal for bio-medical applications. Talking about his new TEM camera, Mr Mackenzie said “We are now able to capture much better quality images and with the JEOL TEM we are carrying out tomographic imaging as well. The new camera is easy to use which allows us to more quickly train users in its operation. This is especially important in a multi user facility such as ours. The camera system on our previous TEM gave us just 1024x 1024 pixel images, compared to the 4872 x 3248 pixel images with our new AMT camera. We can capture a much larger field of view and can use lower magnifications. The AMT software is easy to use and images are saved in TIFF format, so that they can be opened in any imaging software. The AMT camera also offers good value for money.”

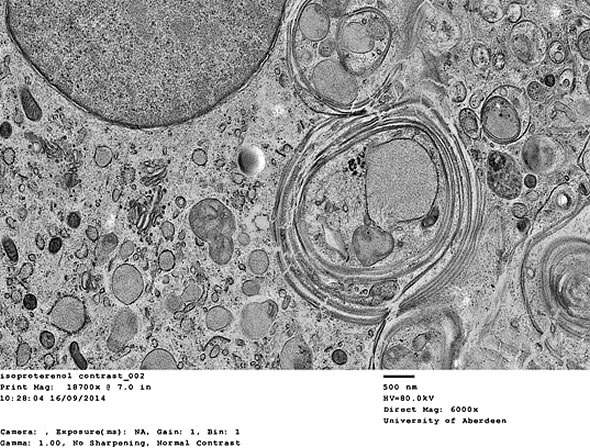

Selecting a single image to illustrate the camera performance is a challenge. A section of images will be published in a Deben applications note on the ActiveVu later in the year. In the meantime, the user group has selected an image from Miriam Lettieri, a research assistant at the Rowett Institute of Nutrition and Health, University of Aberdeen. It shows lysosomes in 3T3L1 cells. Here, the 3T3L1 cells were differentiated into adipocytes and then high pressure frozen (HPF) in a Leica EMpact 2 and freeze substituted in a Leica AFS to HM20 resin. Ultrathin sections (90nm) were stained with Uranyl Acetate and Lead citrate.

Leading worldwide supplier, AMT, created the first live imaging high resolution TEM CCD camera system in 1992. They aim to provide imaging systems that improve laboratory efficiency and productivity through using low noise cameras with modern CCDs and fast progressive scan readouts. Electronics and software complement the camera characteristics and are tuned to provide the most efficient TEM image acquisition. The lenses are designed specifically for TEM applications providing outstanding resolution and sensitivity compared to alternative suppliers. This makes this design of optical solutions a serious alternative to fibre optic systems. With exceptional reliability, AMT systems do not require beam blanking or water cooling nor require bellows or sliding O-rings.

UA user at the Microscopy & Histology Core Facility at the University of Aberdeen using the JEOL 1400 plus TEM together with the high performance AMT TEM camera from Deben.

To obtain full details of the Deben applications and product portfolio, please visit www.deben.co.uk.

About Deben

Deben are a UK precision engineering company specialising in the field of in-situ tensile testing, motion control and specimen cooling for microscopy applications. Established in 1986 and named after a Suffolk river, Deben now operate from a large, modern business unit in Woolpit near Bury St. Edmunds in Suffolk. The product groups are motor control systems, in-situ micro-tensile stages, Peltier heating & cooling stages, detectors for SEMs and electro-static beam blankers. The company also makes custom and OEM versions of these products to specifically meet customer requirements.

Deben provide consultancy, design and prototype manufacturing services. In house facilities include SolidWorks and SolidEdge 3D CAD and COSMOS finite element analysis software, CNC machining, electronics design and manufacture and software design using Visual C++, Microsoft.net and DirectX. Utilising these resources and experience, Deben manufacture products for OEMs and end users in the UK and overseas.

Deben UK Ltd. is a subsidiary company of UK based Judges Scientific plc. For details on Deben and all its products & solutions, visit www.deben.co.uk.

Source: www.deben.co.uk