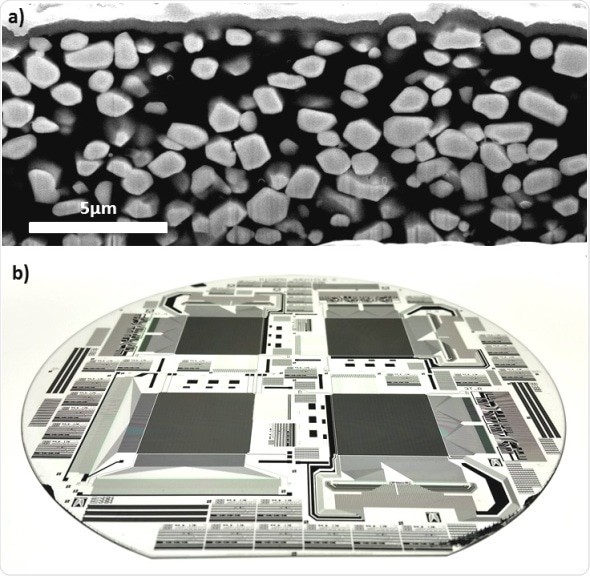

DICOMO 5μm view of (top) Scintillating micro-particles (white) embedded in an organic semiconducting bulk (dark) and (below) Active pixel metal-oxide backplane.

With over 22 million X-rays being recorded in the NHS in England last year, they are a diagnostic test that most of us are familiar with. Scientists have often sought to reduce harmful ionizing radiation, the high-energy particles that penetrate tissue to reveal internal organs and bone structures that can damage DNA, from single x-ray records or CT scans.

Although this ionizing radiation can be reduced, traditionally it has come at the expense of the image resolution and type of detector.

As a result of the two types of X-ray technology that exist today, diagnosis can only take the form of a high resolution image, seen with ‘Direct Converters’ that are used in Mammography, or a low radiation dose, seen with ‘Indirect Converters’ that are used in Radiography or Fluoroscopy.

Direct converters are based on semiconductors which directly convert X-Rays into electrical signals (e.g. amorphous Selenium), while indirect converters make use of scintillators (e.g. Caesium Iodide) which emit light upon X-Ray irradiation, and convert it into electrical signals by a photodetector.

One is fine for micro anomalies in breast tissue, the other for larger structures like bones or larger blood vessels, but never has there been a hybrid of the two.

Combining these advantages the DiCoMo, (or ‘Direct conversion hybrid-organic X-ray detectors on metal oxide backplane’) project is developing a new digital X-Ray detector capable of producing high resolution images that, in the envisioned product, rival a 16 mega pixel photograph. With lower radiation doses and at a fraction of the cost this is excellent news for staff at hospitals like radiologists or dentists and patients, particularly small children.

Current indirect detectors, which offer a lower dose of radiation, generate light in all directions as soon as an X-ray photon is absorbed in it, hitting a large number of pixels on the photodetector array and creating limited spatial resolution. Project coordinator Dr Sandro Tedde of SIEMENS HEALTHINEERS explains:

The result is like a blurred photograph, or ‘frosted’ bathroom glass, where light bounces off the surface at different angles. In indirect converters there is always a compromise between resolution and sensitivity.

DiCoMo combines the advantages of both technologies by fusing radical innovations in the frontplane, the part of the device converting X-rays into electrical signals, and the backplane, which stores and drives the signals from the pixels to the readout circuitry and digital image reconstruction.

It works by getting an ‘indirect converter’, with low radiation output, to behave in the way we would expect to see a ‘direct converter’ perform, a technique DiCoMo calls the “Quasi-Direct” effect. This allows the images to have the high resolution typical for direct converters by using scintillators and the great sensitivity they enable.

Contrary to the indirect approach, where the scintillator is stacked on top of the photodetector array, the DiCoMo technique embeds the scintillator into the photodetector itself, meaning the absorption of light occurs right where it has been generated and no optical ‘crosstalk’ between pixels occurs. This produces high spatial resolution typically seen in direct converters, a result never before achieved.

DiCoMo’s second innovation is in the technology of the backplane, which is developed by TNO and IMEC, where the ‘Active Pixels’ made from metal-oxide thin-film transistors amplify the charge within the backplane pixel itself, creating a stronger signal in situ.

Active pixels are state of the art in CMOS imagers but have not been used so far in imagers based on transistor technologies made of amorphous semiconductors, like those used in medical X-Ray detectors. A customised readout chip (ROIC) developed by the partner ICSense is key for enabling the readout of the active pixel array and achieving the envisioned high frame rates.

“Similar to CMOS camera technology, where millions of tiny photo sensors and transistors create an electrical current when exposed to light, our Active Pixel technology gives us a ‘louder’ signal at a much higher frame rate than ever before” says Dr Tedde.

“The fastest flat panel X-Ray detectors with state of the art technology deliver around 60 frames per second, whereas DiCoMo aims to double this by capturing at 130 fps, permitting a physician to examine vital organs not only in high resolution, but also moving images in slow motion.”

DiCoMo came up with the solution of using a hybrid X-ray absorption and conversion layer by embedding scintillating micro-particles into an organic semiconductor photo detecting bulk, in a pattern resembling the raisin parts in a raisin loaf. This prevents the light from being widely spread over several pixels since the light to electrical signal conversion occurs in the same pixel where the X-ray photon has been absorbed preserving the spatial information.

Earlier last year, the DiCoMo consortium received funding of €3,277,034.75 from the Photonics Public Private Partnership, via the European Commission’s H2020 program for a three year research project in a Research and Innovation action. Hoping to have these revolutionary new x-ray detectors ready within 5 years, Tedde is excited about the implications for the future:

The versatility of this device is impressive not just for its use medical, veterinary and dental surgeries, but also with its increased speed and resolution the DiCoMo detector would be really attractive to customs or the military for scanning relevant material.

Coordinated in Germany by SIEMENS HEALTHINEERS, the project is made up of partners from Switzerland, Belgium, Netherlands, and Italy, including BASF Switzerland, Belgian microelectronics center IMEC, Dutch research company TNO, Belgian chip designer ICsense NV and Italian simulation specialist MorphwiZe.