On 11 July 2017, Epigem celebrated the completion of its research into Aflatoxin detection in milk, as part of the EU-funded SYMPHONY project. At the same time, the company announced that it has filed a patent based on this work.

The industrial partners Epigem and Lionix developed novel microsystem solutions in the form of sample preparation using microfluidics (Epigem) integrated with detection using micro-optics (Lionix). Further development of the analytical solutions and instrumentation created will benefit both animal welfare and food safety threatened by climate change.

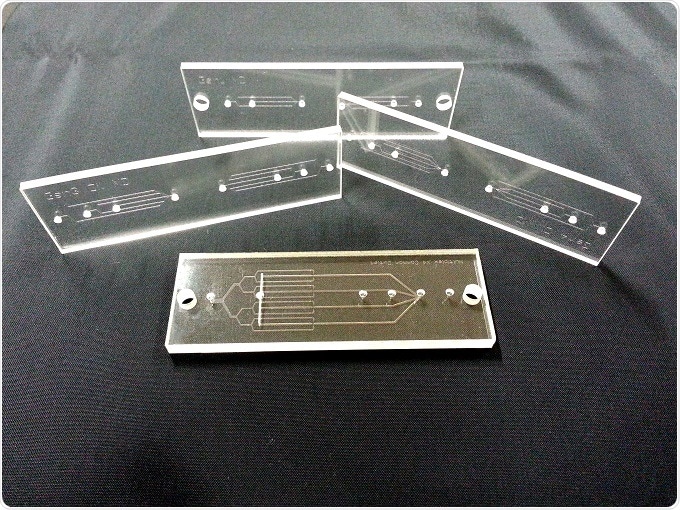

Epigem has deployed its expertise in microfluidic technologies to provide a miniaturised device capable of sample handling, purification and concentration.

The project developed a number of options such as de-fatting which was as efficient as a centrifuge and enables animal tests times to reduce from hours to minutes, depending on sample size. This included a micro-fluidics solution from Epigem by numbering up multiple devices.

This was an essential first step in producing an instrument which analyses aflatoxin in milk quickly and efficiently at the dairy gate, the farm gate or the cow’s udder.

The next phase of the project for Epigem was to concentrate the toxin from the de-fatted milk by a factor of at least 50, trapping up to 30%, to enable detection levels better than 25 parts per trillion of aflatoxin.

The concentrator used a high surface area of material, packed into a small contained volume with the following properties;

- The high surface area element did not severely restrict the flow of prepared sample or filter out particulates i.e. block under flow conditions.

- The high surface element created a controlled pressure drop to force interaction of sample material with available surface area.

- The material forming the element enabled trapping of the desired molecule (in this case Aflatoxin).

- The trapped molecules were then released into a much lower volume, thereby leading to a much higher concentration.

The concentrate was then analysed at the University of Trento using Lionix BV optical detection technology. FBK, based in Italy, led the project and contributed to sensor development, surface biochemistry and microfluidics, while Acreo in Sweden provided expertise in the surface chemistry for trapping, and the testing of the concentrator.

FBK and Acreo integrated the technologies in the final demonstration, at a Concast dairy in Italy, one of the partners. Quadrachem Laboratories (QCL) provided practical expertise and made the business case for this analytical instrument in the dairy industry.

Dr Tim Ryan, MD of Epigem, said: “This was a challenging project which has significantly progressed the detection of Aflatoxin in milk, a problem likely to increase because of global warming.

“I am pleased at the progress we have made and the potential in the future, and we have filed a patent to help secure the commercial opportunities. The work completed through this project has the potential to save lives.”

Aflatoxin contamination in Europe is a growing problem, albeit from a low base, while there are major problems in India, Africa & S America. Dr Ryan added: “Epigem is now looking to address problems of contamination of milk in these areas, and we are seeking new partners to develop and trial the technology where it is most needed.”

SYMPHONY’s (European Community's Seventh Framework Programme (FP7-ICT-2013-10) under grant agreement n° 610580) aim was to deliver an integrated systems project to improve the quality and safety of milk by the rapid detection of aflatoxin M1 in milk for the dairy industry, which could ultimately enable testing of these carcinogens to be carried out at an individual farm or dairy level.

Epigem manufactured the microfluidic components used for milk sample preparation. The company’s product development strategy is to continue to build a portfolio of complementary technologies providing a sustainable business for the manufacture of key components and modules with increasing levels of integration (e.g. process control electronics) for sale in instrumentation in a range of healthcare applications where there is a well-defined unmet need.