At POWTECH 2019 from 9 to 11 April in Nuremberg, trade visitors will experience the entire range of innovations in mechanical processing technology. This also makes this international trade fair the leading forum for decision-makers involved in the development, manufacture and analysis of pharmaceutical, cosmetic, dietary and health food products. In these product groups, manufacturers that can respond the fastest to changing customer needs have the advantage. With the over 800 exhibitors from 32 countries at POWTECH 2019, solutions to provide more speed and efficiency in production are therefore an important focus.

At POWTECH, more than 380 of the around 800 exhibitors in total will be presenting innovations for pharmacteutical production.

One of the biggest challenges in the pharmaceutical, cosmetic and health food sectors has always been to cut development times. Bosch, for example, has developed a solution for manufacturers of solid oral dosage forms and will showcase this approach for the first time in Germany at POWTECH 2019. The Xelum R&D laboratory solution substantially reduces the time from laboratory to continuous production. The exhibitor says that this is the first laboratory system that enables various excipients and active ingredients to be dosed, mixed, granulated and dried. It is also the first system that lets pharmaceutical engineers develop formulations for both continuous and batch production.

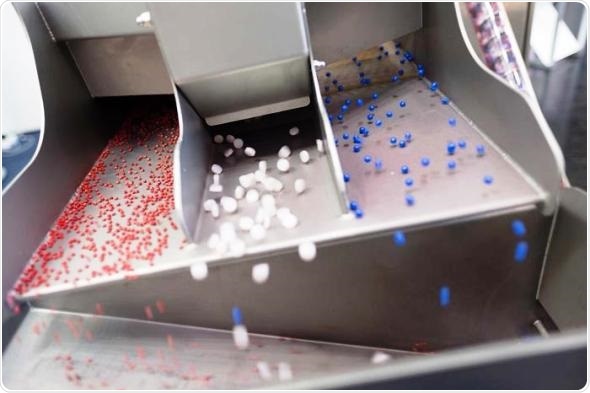

Fritz-Martin Scholz, Product Manager for Xelum at Bosch Packaging Technology, explains the details: “In continuous production, one of the biggest challenges is the precise dosing of the starting materials. Our new approach means that in contrast to the usual continual mass flow, the Xelum R&D doses excipients and active ingredients as a discrete mass. To this end, individual packages known as X-keys are dosed, mixed and granulated in batches which run continuously through the process chain. They are then removed successively from the system and transferred to bins. This not only reduces the complexity of the process but also improves the accuracy and quality of the end product. Moreover, the starting materials are traceable at all times.”

The goal: shorter development cycles and time to market

Bosch uses the fluid bed processors developed by its subsidiary Hüttlin for granulation in the Xelum R&D. There is no need to transfer wet granulate, as granulation and drying take place in the same process area. This means that production volumes ranging from less than 250 g through to 10 kg per hour can be processed in automatic cycles. As a result the system is not just ideal for R&D purposes but also for pilot production or the manufacture of orphan drugs. It is optionally available as a completely self-contained unit and can also be used for the development of potent active ingredients. Scholz stresses: “The new laboratory system works with identical components and process parameters as our Xelum production platform, which means process parameters can be directly transferred 1:1. As a result, no scale-up is necessary and pharmaceutical specialists achieve shorter development cycles and time to market.”

At the trade fair, more than 380 other exhibitors offer innovations specifically for pharmaceutical production. A total 800 companies in the six exhibition halls at POWTECH provide a diverse range of technologies and solutions for pulverizing, mixing, separating, filtering, agglomerating and associated processes that is unrivaled worldwide.

Supporting program for pharmaceutical experts

Experts from the pharmaceutical sector can also look forward to a special highlight – the Pharma.Manufacturing.Excellence Forum in Hall 3. Organized by the APV (International Association for Pharmaceutical Technology), the forum comprises a series of presentations by experts focusing on solid dosage forms, offering added value to those seeking professional development opportunities. The (English language) program can be downloaded from www.powtech.de. Directly adjacent to the forum and APV lounge, suppliers of pharmaceutical excipients will have their own dedicated area for the first time and will thus provide a fitting complement to the range on display for pharmaceutical experts at POWTECH. The international PARTEC Congress for Particle Technology will take place parallel to POWTECH 2019 and expects to welcome more than 500 delegates. It is sponsored by VDI-GVC (Association of Process and Chemical Engineering).