Bruker today announced the introduction of its new Dynamic Fat Crystallization (DFC) analysis method using time-domain nuclear magnetic resonance (TD-NMR) spectroscopy. This DFC method was developed in collaboration with partners Sollich KG, August Storck KG and the Fraunhofer Institute for Process Engineering and Packaging (IVV). It enables quality control (QC) managers to decide quickly whether fats and fat blends should be accepted or rejected, according to the fat crystallization pattern.

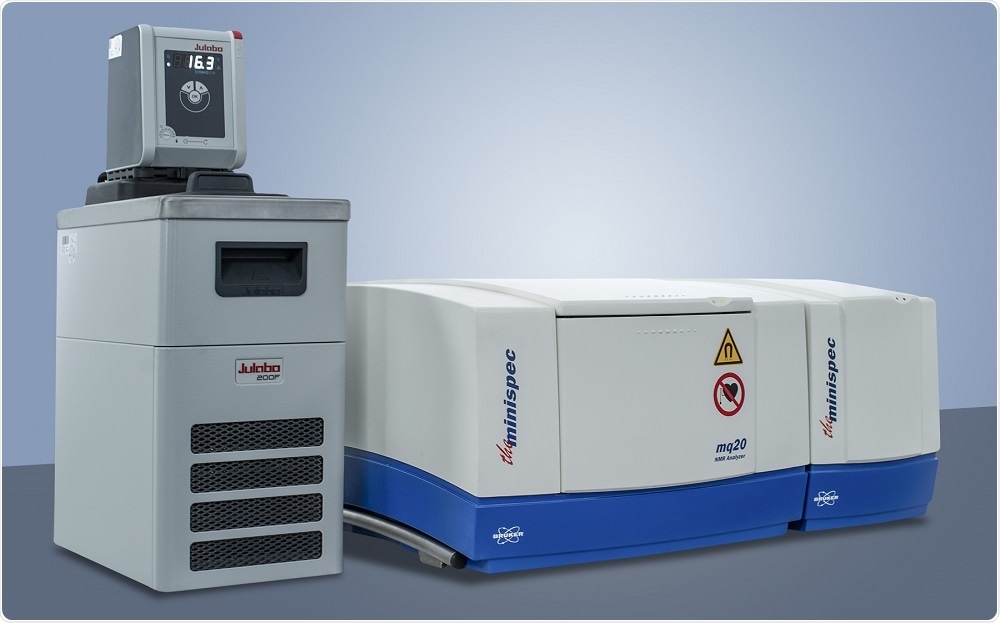

The minispec® mq20 NMR Analyzer.

Fat crystallization analysis is based on the acquisition of solid-fat content (SFC) information in fats and fat compositions, such as cocoa butter, cocoa butter equivalents, and special fats. Current determination methods include dilatometry and differential scanning calorimetry (DSC), which can take up to 45 hours.

Compared to these traditional methods, Dynamic Fat Crystallization analysis using Bruker’s minispec®mq TD-NMR and Dynamic Center™ software, provide dynamic crystallization patterns of fats and mixtures within just two hours, including sample preparation. This significant time saving drastically speeds up decision-making about the quality or end use of fats in the production process.

Beyond the clear speed advantages, Dynamic FAT Crystallization analysis is easy to use for NMR non-specialists. While existing techniques measure isothermal crystallization for a defined period of time, our new DFC solution uses quasi-static crystallization to record values in real time.”

Thomas Spengler, Senior Market Manager for Food, Feed and Beverage Markets, Bruker BioSpin

Marcel Boening, Process Engineering Manager at Sollich KG, commented: "For our customers in chocolate manufacturing, ensuring a consistent quality of raw materials is very advantageous for the continuous operation of our machines. Using the Dynamic Fat Crystallization analysis method, our customers can quickly check the crystallization of cocoa butter upon delivery, and the first step towards producing a perfect product is achieved.”

Isabell Rothkopf, Group Manager Chocolate Technology at Fraunhofer IVV Freising, added: “As a research institution, we depend on reliable methods for the characterization of a wide variety of products. With this new DFC development, we are advancing technologically challenging processes, e.g. in chocolate manufacturing. The Dynamic Fat Crystallization method offers a simple and fast way for the investigation of cocoa butter and cocoa mass. This is not only important for our research work, but also to efficiently support our industrial partners in key QC questions.”

Dynamic Fat Crystallization Based on the Indirect Solid Fat Content (SFC) Method