As specialists in silicone-based combination devices, Trelleborg’s healthcare and medical operation will be attending Pharmapack this year, with experts available to support medical device manufacturers and pharmaceutical companies in this booming technology.

Drug-eluting devices, whether implanted or on the skin, are becoming an increasingly popular way for monitoring chronic-disease, such as heart condition or glucose levels, for guarding against inflammation and infection, as well as for drug delivery.

The trend toward adding Active Pharmaceutical Ingredients (API) to devices and new delivery mechanisms is rapidly gaining traction in the healthcare and medical industry. According to a report by Allied Market Research published in September 2018, the global drug-device combination products market is expected to reach $139.2 billion by 2025, representing a compound annual growth rate of 6.9% on 2018.

Andreas Schmiedel, Technical Manager Healthcare & Medical Europe, Trelleborg Sealing Solutions, who will be presenting a technical paper on mixing API with silicone at Pharmapack, discusses the advantages and manufacturing considerations of the two main processes of combining silicone with an Active Pharmaceutical Ingredient (API).

“The two processes Trelleborg uses are Liquid Silicone Rubber (LSR) combined with an API before being fabricated into a silicone part. The second is a finished silicone part immersed in a drug-loaded solvent to impregnate it with an antibacterial or antimicrobial.

“In the pre-fabrication method, an API is usually combined with silicone immediately before extrusion, molding or sheeting. The API is invariably added to the silicone in powder form, as this is typically the most stable form of a drug.

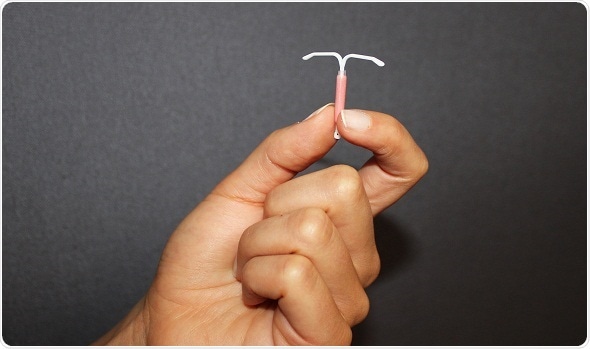

“The key advantage of adding an API to silicone before fabrication is that an accurate mass ratio of drug to silicone can be achieved, typically plus or minus 5%, or better, of the target mass ratio. The process is ideal for creating devices designed to deliver a precise dose of medication, such as a skin patch for pain medication, a vaginal ring for contraception, or a bio-absorbable device for treating eye disease.

“However, there are several manufacturing factors to consider when combining APIs with raw silicone. First, some APIs can react, or chemically interact, with the curing system of silicone. Secondly, the upper stability limit of many drugs is relatively low compared to the cure temperature for silicone. Thirdly, many APIs are hazardous in powdered form. Finally, all drug delivery combination devices still need regulatory approval, even if the drug was approved in a different form.

“Looking at the alternative process of adding API to an existing silicone device through immersion. There are several advantages to this: it’s a relatively mature technology, the development timeline is usually shorter because the design/manufacturing process for the device does not change, drugs with lower degradation temperatures can be used, the bar is often lower for FDA approval, and the results are highly repeatable.

“The process involves adding an API to solvents that completely solubilize the drug. The solvent swells the silicone, allowing the API to impregnate the vulcanized piece. After the immersion period, the component is removed from the solution and the solvent evaporates, leaving the API impregnated in the silicone matrix.

“This method, therefore, is not as precise as adding an API to raw silicone from a mass ratio perspective and is most suitable when precise drug-release rates are not critical. For example, the amount of anti-inflammatory released from a pacemaker lead does not need to be controlled in micrograms per day. Rather, the API is there to improve the safety or efficacy of the device, typically requiring a strong presence of the drug for the first two to four weeks after placement.

“A number of variables, including the type of drug and the thickness of the materials, determine the amount of API that can be impregnated into the silicone. Due to this, it is important that development and testing procedures are used to determine the degree of impregnation.

“It should also be born in mind that the immersion method for combination device production is limited to certain materials; silicone and some types of thermoplastic elastomers.

Trelleborg experts will be on stand G72 in hall 7.2 at Pharmapack in Paris, France, February 5 and 6 to discuss combination devices and their development in further detail.

On Thursday, 6 February at 11am, Andreas Schmiedel will be presenting a technical paper, “Products and Processes for Life-Changing Technologies”, at Pharmapack that will focus on mixing of APIs with silicone.