A group of researchers led by Professor Alvaro Mata from the University of Nottingham, along with others from Queen Mary University London, has successfully created a biomaterial that could be used for the creation of tissues that could form blood vessels. The study titled, “Disordered protein-graphene oxide co-assembly and supramolecular biofabrication of functional fluidic devices,” was published in the latest issue of the journal Nature Communications.

For this study, the team of researchers used graphene oxide and a protein that they 3D printed to create a tubular structure. This tubular structure could mimic the properties of a vascular structure such as arteries or veins they wrote.

Lead author of this cutting edge biomedical engineering study, Professor Mata, said, “This work offers opportunities in biofabrication by enabling simultaneous top-down 3D bioprinting and bottom-up self-assembly of synthetic and biological components in an orderly manner from the nanoscale. Here, we are biofabricating micro-scale capillary-like fluidic structures that are compatible with cells, exhibit physiologically relevant properties, and have the capacity to withstand flow. This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs, meaning treatments could potentially reach patients much more quickly.”

What was done?

The international research team wrote that there is an opportunity to assemble material using exact molecular precision when they used “supramolecular chemistry.” They explained that despite this, the actual creation of functional assemblies has been elusive to date. They used “disordered proteins” and graphene oxide (GO) in this experiment to see if these were assembled using a “diffusion-reaction process,” and there were transitions typical creation of “hierarchically organized materials” was possible. These molecules were stable, they wrote.

In this study, they described molecular dynamic simulations to see how they could form these assemblies and create useful products. They noted that using these assemblies, they could create thin capillary-like microstructures that could act as capillaries. These structures were fluidic they wrote and could withstand the flow of liquids within them. If proven, these could open up a new avenue in the creation of vasculature wrote the researchers.

They concluded, “Our study presents an innovative approach to transform a rational supramolecular design into functional engineering with potential widespread use in microfluidic systems and organ-on-a-chip platforms.”

The materials used

The team used protein with graphene oxide. They wrote that the proteins were disordered, and these regions of the proteins were flexible. The team explained that ordered proteins were those with a β-sheet and α-helix, while disordered proteins were shaped like a random coil. Both types had regions that played a role in its functions.

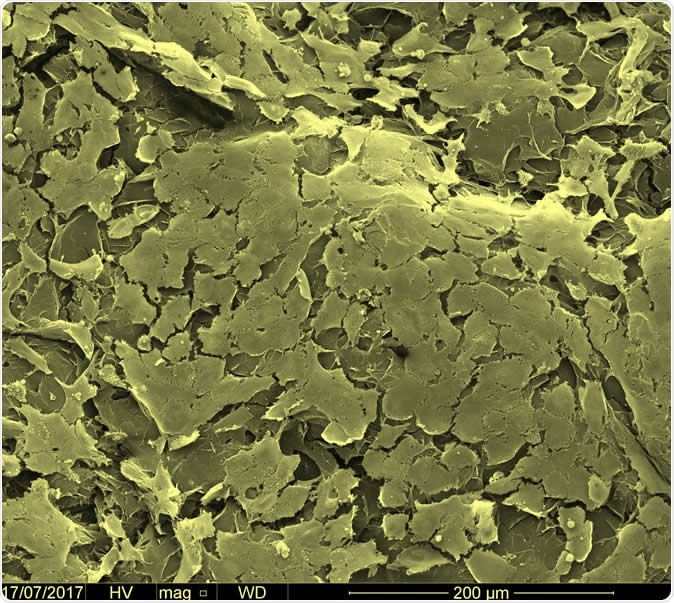

Scanning electron microscopy image depicting endothelial cells growing on the surface of the printed tubular structures. Image Credit: Professor Alvaro Mata

These regions could then assemble with the graphene oxide, they wrote. Different interactions between the materials could help in different assemblies, they explained. They wrote about the graphene oxide sheets, “We used GO sheets of two different average lateral sizes, including larger GO (GO-L) measuring 10.5 ± 4.5 µm and smaller GO (GO-S) of 2.3 ± 0.9 µm, both exhibiting a typical hydrophobic surface and negatively charged carboxylic groups on their periphery.”

They wrote that a 3D printing bioink could be created from these materials and structures as small as ten nanometres could be created using this bioink. These structures would have detailed microscopic features and geometries, they wrote.

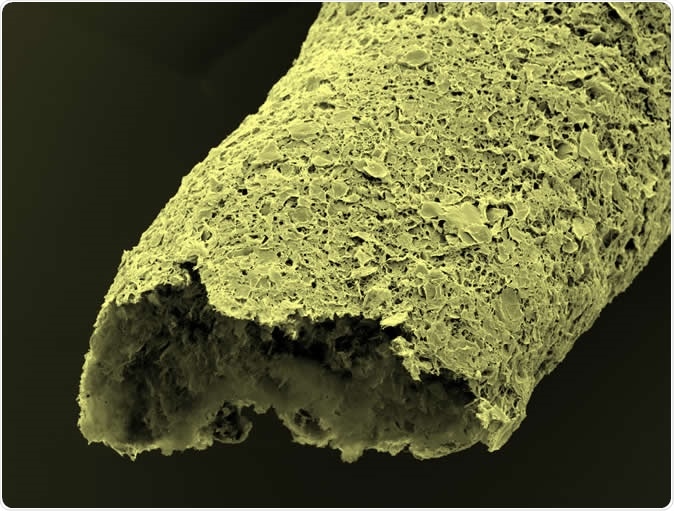

Close-up of a tubular structure made by simultaneous printing and self-assembling between graphene oxide and a protein. Image credit: Professor Alvaro Mata

Impact of the study

Researchers Dr. Yuanhao Wu explained, “There is a great interest in developing materials and fabrication processes that emulate those from nature. However, the ability to build robust functional materials and devices through the self-assembly of molecular components has until now been limited. This research introduces a new method to integrate proteins with graphene oxide by self-assembly in a way that can be easily integrated with additive manufacturing to easily fabricate biofluidic devices that allow us to replicate key parts of human tissues and organs in the lab.”

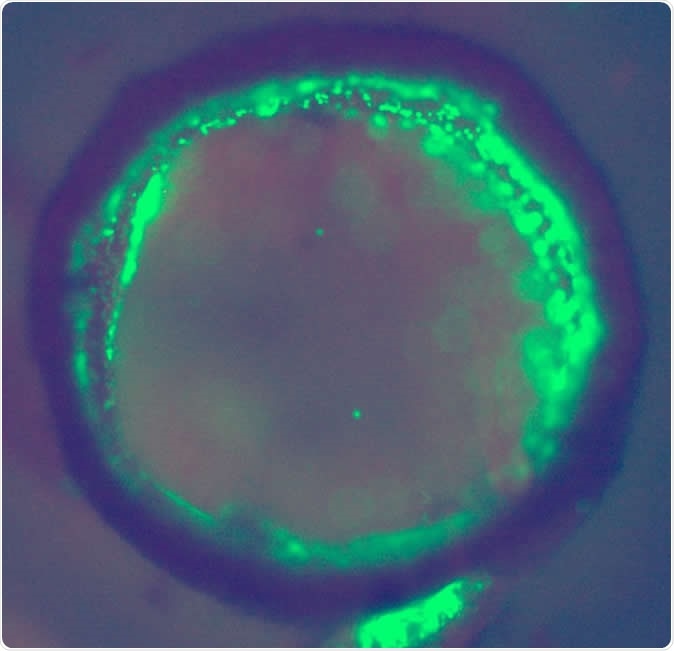

Cross-section of a bioprinted tubular structure with endothelial cells (green) on and embedded within the wall. Image credit: Professor Alvaro Mata

The team wrote in conclusions about the future impact of the study, saying that this system, “offers an exciting possibility to develop complex and functional biohybrid devices with a high level of biological relevance by supramolecular processing.” They wrote that this study proves that molecular assemblies could help create functional devices that would be robust and fit for use. They added, “assembly, biocompatibility, and bioactivity” were the three robust properties of these combinations, and these could open, “new opportunities for engineering more complex and biologically relevant tissue-engineered scaffolds, microfluidic systems, or organ-on-a-chip devices.” This could be a bridge between supramolecular design and functional and reproducible biomedical engineering.

Journal reference:

Wu, Y., Okesola, B.O., Xu, J. et al. Disordered protein-graphene oxide co-assembly and supramolecular biofabrication of functional fluidic devices. Nat Commun 11, 1182 (2020). https://doi.org/10.1038/s41467-020-14716-z