Osteopore International Pte Ltd, a Singapore-headquartered company leading the way in regenerative bone implants, is proud to announce the success of its technology in a new medical procedure that took place in Brisbane, Australia, in December last year. Pioneered by surgeon Dr. Michael Wagels, Deputy Director of Plastic and Reconstructive Surgery at Princess Alexandra Hospital, the 11-hour surgery involved the implantation of Osteopore's 3D printed bioresorbable polycaprolactone (PCL) regenerative bone implant, using an innovative surgical technique that transplants a tissue flap from the patient's knee, and was performed on Mr. Brodie Ellis to encourage the regrowth of parts of his skull.

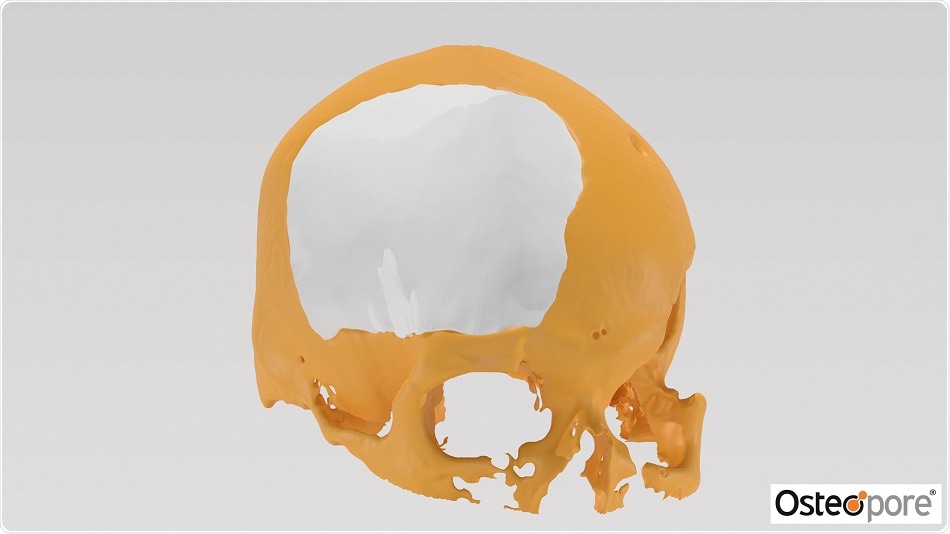

3D render of Osteopore’s customised implant fitting into a skull defect

The cranioplasty procedure called for a patient-specific customized implant, which was designed by the Osteopore team using the patient's CT scan in consultation with Dr. Wagels. Sitting perfectly on the contour of Ellis' skull, the biomimetic structure of the 3D printed regenerative implant introduced a patented, interconnected porous scaffold that mimics the natural cancellous bone microstructure. This mesh-like structure promotes blood vessel infiltration which is paramount to bone and tissue regrowth. The PCL material of the implant is designed to be then gradually resorbed and metabolized by the body over an 18 to 24 months period, with no foreign material left in the skull once healing is complete.

Case study: Mr. Brodie Ellis' motorcycle accident

In December 2018, Mr. Brodie Ellis, a 26-year-old Australian man, had suffered a Stage 4 brain injury and a severely broken leg from a motorcycle accident in Vietnam. On top of having to amputate his left leg, the accident had also left him having to remove and replace certain parts of his skull with plastic implants.

Unfortunately, according to Dr. Wagels, "one of the [plastic] implants [had become] exposed and developed an infection. Because the implant had no blood supply, the infection just kept getting worse and worse, so it had to be removed. This left Brodie with headaches and a contour deformity of the skull."

To treat these problems, Dr. Wagels decided to recommend Ellis a cranioplasty procedure that would use Osteopore's 3D printed implant to replace the section of missing skull. This PCL bone implant would have the ability to encourage natural bone regrowth, thereafter disintegrating into carbon dioxide and water with no foreign material left in the skull, reducing post-surgical or removal surgery complications and significantly minimizing infection rates.

Post-surgery results and success

As expected, just weeks after the cranioplasty surgery, computed tomography (CT) scans of Ellis' skull showed that Osteopore's 3D printed regenerative PCL bone implant had successfully enabled new bone to form within the scaffold, with little complications post-surgery.

The latest CT scan taken 8 weeks after the operation shows bone forming both on the outside and inside of the implant, indicating the body has recognized the implant as broken bone that needs to be healed. The special thing about Brodie's implant is that it is completely absorbable, so it will disappear as the new bone forms within and around it."

Dr. Michael Wagels, Deputy Director of Plastic and Reconstructive Surgery at Princess Alexandra Hospital

In less than a month since the cranioplasty, Ellis was discharged from Princess Alexandra Hospital, and has been able to function independently at home while regaining his strength at the gym.