In this interview, News-Medical talks to Alan Thomas from ZwickRoell UK about materials testing in the pharmaceutical and medical industry.

Why is reliable medical and pharmaceutical device testing important?

Quality assurance in the medical engineering and pharmaceutical sectors places the highest demands on testing technology in terms of hardware, software and documentation.

These industries are heavily controlled by stringent laws and regulations. That is why safety requirements are even more important than in most other industries, since these products, from injector pens and implants to sterile packaging, directly impact humans.

Quality control that satisfies these requirements involves not only product development, production and packaging of medical and pharmaceutical items in compliance with the legal framework and applicable standards, but must also minimize risk to patients and users.

ZwickRoell offers the optimum solutions for mechanical tests required by the medical and pharmaceutical industries, with flexible, modular testing systems, purpose-designed specimen grips and tooling and intuitive software to equip laboratories efficiently and economically, saving customers time and money.

Our extensive product portfolio caters to virtually every segment - from medical and pharmaceutical packaging to surgical instruments, orthopedics and biomaterials.

An ever-increasing demand is placed on software employed in these sectors to facilitate the documentation and traceability of completed actions.

These demands are satisfied by the option of ‘Expanded Traceability’ as required by FDA 21 CFR Part 11, which is available for ZwickRoell’s testXpert III testing software, optimally supporting the operator with test tasks.

A significant element of process validation in these sectors is the technical review of individual plants and devices. This qualification is also required for ZwickRoell materials testing systems used in these sectors, because test systems are subject to various legal requirements, for example, Medical Devices Directive 93/42/EEC or regulations, such as FDA 21 CFR Part 11 and EU GMP Guideline Annex 11.

ZwickRoell provides support for customers in the DQ/IQ/OQ qualification stages for material testing systems in the form of comprehensive, individually tailored qualification documentation in accordance with GAMP5 and current guidelines, and during the on-site qualification procedure.

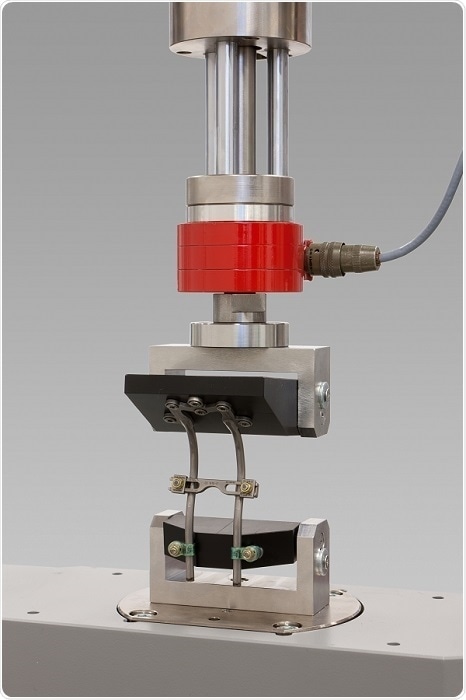

ZwickRoell Multi-Station Syringe Testing System. Image credit: ZwickRoell Gmbh Co. KG

Can you provide an overview of ZwickRoell and its approach to being a trusted partner for the medical and pharmaceutical industries for over 40 years?

ZwickRoell has been supplying a diverse range of testing products to the medical engineering and pharmaceutical industries since the 1970s. Through the provision of well-engineered, intelligent testing solutions, we have gained the confidence of international product manufacturers, research institutes and certification authorities.

What are some specific examples of areas where ZwickRoell’s intelligent testing solutions can be applied?

ZwickRoell’s wide range of testing systems features a modular design, enabling optimum adaptation to the customer’s specific testing requirements.

We provide an extensive portfolio of testing solutions, from those designed to accommodate standard-based tests via manual operation, to complex, fully automated testing systems that do not require a machine operator.

Our intelligent testing solutions ensure that we can offer the right product for every application.

In addition to testing systems that cater for the fundamental challenges associated with materials technology, we provide comprehensive testing solutions for all relevant medical and pharmaceutical segments, including:

- Syringes and injectors (which are used for the administration of parenteral drugs)

- Catheters and stents

- Biomechanics

- Dentistry

- Latex and rubber products

- Medical textiles

- Packaging

- Medical implants

- Surgical instruments and test equipment that is employed for medical research purposes

Therapy injection systems such as syringes, needles and injector pens are critical for proper medical treatments. What advantages does ZwickRoell’s automated testing offer for injector systems?

Reliable test results are a basic requirement when testing medical products.

Extensive testing system automation brings many advantages, including an improvement in test result reproducibility, the elimination of potential machine operator influence, simplification of test validation, and of course, the ability to cope with high productivity throughput.

Auto-injectors are medical devices that are employed to enable patients to safely administer parenteral drugs and are, therefore, subject to stringent quality control.

Previously, parameters such as the firing time and duration of drug expulsion could only be measured manually.

ZwickRoell has engineered a solution for the automated determination of the actuation force, firing time, drug expulsion speed, together with the active-ingredient profile whilst the length of the extended needle is determined via two lasers.

The evaluation of all the test data is performed time-synchronously via the ZwickRoell testXpert III testing software. Scales are additionally incorporated into the testing system to determine the amount of active ingredient delivered and a microphone can be employed to detect the activation noise of the auto-injector.

The application of automated testing systems for injectors ensures the highest level of test result integrity in combination with a volume of test throughput that is simply not achievable when using a manually operated system.

ZwickRoell Spine Implant Test Fixture. Image credit: ZwickRoell Gmbh Co. KG

Describe the process of testing products such as catheters and stents?

Catheters are medical devices in the highest risk category and are subject to strict quality requirements. Development work on catheter and guidewire systems includes attempts to reduce the coefficient of friction and the breakaway force.

ZwickRoell has developed a horizontal testing system that enables the determination of shear forces in a simulated catheter insertion with extremely high accuracy.

The frictional behavior of the catheter is measured by pushing it through an artificial artery, known as the ‘tortuous path’. The test is carried out in a horizontal orientation to closely replicate the physiological status of a patient during the surgical intervention.

Tests can be conducted either in dry conditions or with the test specimen immersed in a temperature-controlled medium containment chamber. It is also possible to carry out tests with or against a liquid flow.

Stents are subject to significant loads on insertion and while they are in place in blood vessels or ureters and must be tested to ensure they are fit for purpose. Together with obtaining accurate material characteristic values, the determination of radial compression strength is the most important test to evaluate stent performance.

Stents must exert a radial force which is sufficient to ensure that the device remains fixed in the previously narrowed location and to prevent renewed constriction of the blood vessels. ASTM F3067 describes the radial compression testing of balloon-expandable and self-expanding stents.

ZwickRoell offers a testing solution that is equipped with a 37°C chamber to simulate tests at body temperature.

The radial force is measured using specially designed radial compression test fixtures - which are available in various diameters and lengths. They simulate the pressure exerted on the stent by the artery, together with the restoring force, by means of segmentally arranged wedge jaws which generate a uniform surface pressure.

The stent is inserted, compressed radially to a minimum target load, and then unloaded.

What does ZwickRoell offer for testing the performance of spinal implants?

Spinal implants, generally consisting of a rod and screw system, are tested under static and dynamic loading conditions in accordance with the procedures described in ASTM F1717.

The implants are mounted in a test fiixture and the use of simulated vertebral bodies improves test reproducibility compared with using human material.

In addition to conducting purely axial tension and compression tests, a pure or combined torsional load can be applied to spinal systems in accordance with ASTM F1717, ASTM F2706 and ISO 12189 standards.

These tests can be optionally performed under physiological or ‘in-vivo’ conditions by immersing the test specimen in a bath containing a temperature-controlled saline solution.

The standard ASTM F2077 describes a series of different quasi-static and oscillating tests to enable mechanical comparison of intervertebral body fusion devices. These include shear, compression and torsion tests, which provide a simplified ‘in-vivo’ simulation of the loads imposed on spinal implants.

As a result of fractures of a vertebral body, or tumors in the area of the spinal column, it may be necessary to replace sections of a vertebral body with an implant that is evaluated by carrying out quasi-static or oscillating torsion tests in accordance with ASTM F2077 and ASTM F1717 standards.

The diverse range of textile medical products and instruments require a wide range of material and function tests. What capabilities are offered to cater to these?

Textiles are used for numerous medical applications, including dressing and treating wounds, a wide variety of suture materials, textile-based implant structures, such as hernia net implants, and surgical drapes and clothing.

These products use a wide range of materials, including natural and synthetic fibers, together with breathable films and material combinations. The many different products used in this area call for a wide range of material and functionality tests.

To avoid individual gauze bandage fibers ‘catching’ on the winding below and preventing reliable unrolling, it is necessary to determine the force required to unwind the bandage from the roll.

For this test, ZwickRoell offers a low force testing machine incorporating a motor-driven unrolling unit and the test sequence is controlled by a specially adapted program from ZwickRoell’s testXpert III software suite.

This special test fixture can also be utilized for pull-off tests on plaster strips, where the test method is described in EN 1939. To measure the adhesive force of wound dressings or other self-adhesive medical products, the specimen is pulled off a metal plate during the test and can be performed at various angles.

However, forces measured in this way are significantly greater than those arising when the dressing is used on the skin. Manufacturers of adhesive products frequently test adhesive force on natural skin in order to detect any sensation of pain by the patient, as well as any skin irritation that may occur.

ZwickRoell machines are used for the characterization of surgical suture materials using conventional tensile tests. During the test the monofilament, multifilament and braided yarn structures must be securely clamped to avoid slippage, which would result in erroneous test data.

Surgical instruments can be divided into holding, grasping and cutting instruments, as well as suture instruments, optics and combined instruments.

ZwickRoell, with the benefit of having an extensive test equipment portfolio, can use our modular design concept to accommodate the testing of surgical components and finished goods. For example, we have supplied equipment that is used to determine the cutting characteristics of ophthalmic scalpels and the wear resistance of bone saws.

ZwickRoell Automated Bottle Screw Cap Testing System. Image credit: ZwickRoell Gmbh Co. KG

Tell us more about the devices created to test medical and pharmaceutical packaging?

Pharmaceutical packaging is highly regulated but with some variation in the details, depending on the country of origin. Several common factors can include:

- Assurance of patient safety

- Assurance of the efficacy of the drug through the intended shelf life

- Uniformity of the drug through different production lots

- Thorough documentation of all materials and processes

- Control of possible migration of packaging components into the drug

- Control of degradation of the drug by oxygen, moisture, heat, etc.

- Prevention of microbial contamination, sterility, etc.

Packaging is often involved in dispensing, dosing and use of the pharmaceutical product and is an integral part of the medical or pharmaceutical product.

Packaging testing covers a very wide spectrum but some of the more commonly used tests include:

- Peel tests on blister packs

- Tablet push-out tests on blister packs

- Compression testing of pills and tablets

- Determination of the residual seal force of drug vials

- Push and turn tests on screw caps

- Determination of the breakaway torque of syringe tip caps

- Compression tests on cardboard packaging

The extensive experience of ZwickRoell enables us to accommodate virtually any packaging test by drawing on our previous knowledge of the sector and where necessary, designing a bespoke solution to satisfy the customer requirement.

How do biaxial and triaxial testing systems expand the capabilities of biomaterial and clinical research?

To enable accurate modeling, the biomechanical behavior of soft biological tissue and its underlying structure must first be precisely determined.

As biological tissues found in the body are continuously subjected to multi-axial loads, research in this area requires a testing machine that has the capability to apply multi-axial loads to the tissue specimen.

The ZwickRoell biaxial testing system incorporates four linear drives which are controlled independently of each other via position, force or strain. Force measurement is determined via load cells, two of each in the X and Y directions.

There are also four electronic measurement and control units, as well as a fluid bath for optimum temperature conditioning of the sample.

To facilitate the determination of the shear properties of soft biological (orthotropic) tissue, ZwickRoell has developed a triaxial testing system that consists of two main components; an upper platform designed to move vertically in the ‘z’ direction, and a lower platform designed to move in the horizontal plane in two directions (‘x’ and ‘y’ directions) perpendicular to each other.

During the test, the tissue specimen is attached to the upper and lower platforms using a thin coating of adhesive and immersed in a temperature-controlled physiological solution.

The lower platform moves relative to the horizontally fixed upper platform, causing the specimen to shear, and the forces occurring in the three orthogonal directions (x, y and z) can be measured simultaneously with a special load cell mounted on the upper platform.

We have also developed a triaxial testing system for characterizing cardiovascular tissues which allow an axial force (strain), an internal pressure (inflation) and a rotational movement (torsion) to be applied to the tissue sample.

The tissue under test is normally located in a bath containing a physiological fluid. Symmetrically moving crossheads ensure that the center of the specimen always remains in the same horizontal position.

Due to the sensitivity of the structures being tested, it is important that strain is measured without affecting the specimen. We, therefore, employ advanced non-contacting measuring instruments for this purpose.

What are some benefits of working with advanced testing software provided by ZwickRoell?

ZwickRoell testXpert III software is the result of close collaboration with users in materials testing and the experience gained from a huge number of successful testXpert installations.

With its intuitive, structured operation, testXpert III is easy to use right from the get-go, incorporating informative icons and clear visual linking of related items to assist the user, while reducing the mouse movement and required clicks.

The software guides the operator through the various stages of a test procedure, from preparing and running the test to the analysis of the test results.

testXpert III is workflow-based, keeping training time to a minimum and enabling efficient, reliable testing. Furthermore, the software can communicate with any IT system so that all test-related data is imported quickly and directly.

Ever-increasing demands are placed on the software used in the medical and pharmaceutical industries to document the traceability of completed actions.

testXpert III’s ‘traceability’ option enables the logging of actions and changes before, during and after the test, making test results and documentation traceable, as well as safeguarding them against tampering.

About the interviewee

Alan Thomas is employed in the Marketing Department at ZwickRoell Limited.

Having spent over 40 years in the materials testing sector, he is keen to ensure ZwickRoell maintain market leader recognition in the supply of advanced testing products and associated customer support.

Alan enjoys using his testing sector knowledge and skills to inform and educate customers regarding the benefits which can be derived from collaborating with a leading, global brand.

His extensive knowledge of materials and component mechanical testing disciplines enables him to develop strong customer relationships and to promote premium testing products and services across a wide range of industry sectors.

About ZwickRoell

With over 160 years of expertise in materials and components testing, ZwickRoell delivers intelligent materials testing solutions for the medical industry, including drug delivery testing systems for syringes and cartridges, autoinjectors, and pen injectors. Our qualification services help ensure compliance to your industry’s stringent testing requirements.

Worldwide presence

ZwickRoell, LP is a member of the ZwickRoell Group, a key player in the global market for materials testing systems. Operating in 56 countries worldwide, the ZwickRoell Group has manufacturing facilities in Germany, the UK, Austria, and China, well as subsidiaries in France, the UK, Spain, the USA, Brazil, Turkey, Singapore, and China.

High quality

ZwickRoell produces most components in-house to ensure increasingly high quality. Our experts understand the individual requirements of the different industries to meet all testing needs with state-of-the-art solutions.

High-tech software and equipment

ZwickRoell testing systems hold many patents and design awards. We offer state-of-the-art testing machines, industry-leading measurement and control software, and A2LA-accredited service and support. Our qualification services help ensure compliance to your industry’s stringent testing requirements and our cutting-edge extensometry and customized test fixtures accommodate almost any testing application.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.