In this interview, News-Medical speaks to Thanh T. Nguyen, a project manager at Innocore Pharmaceuticals, about the mechanisms behind long-acting injectables.

Can you give an introduction to Innocore Pharmaceuticals and your role there?

Innocore Pharmaceuticals is a drug delivery company located in the north of the Netherlands.

Innocore is focused on the deployment of injectable, sustained-release drug delivery products - including a patented polymer base for drug delivery. We develop the project up to the GMP manufacturing stage, supplying products for phase one and phase two clinical studies.

I am a program manager developing long-acting injectables prepared by hot-melt extrusion or in situ forming gel.

What are the benefits of sustained-release drug delivery systems for patients and the healthcare system?

Immediate release drug delivery systems have several disadvantages; for example, they can lead to inconsistent drug plasma concentration in the blood, going over the limit to a toxic level or under the minimum level needed to ensure therapeutic efficacy.

A sustained release or long-acting injectable delivers a stable drug concentration in plasma within the therapeutic range - lower than the toxic level and higher than the minimum effective level.

It can be beneficial to reduce injection frequency, for example, when injecting a drug into the eye. A long-acting injectable may only need to be injected once a month or every six months. We are developing this in partnership with another organization. This increases patient convenience, reduces discomfort, and lowers the inflammation risks and infection associated with injections.

Reducing the number of required injections can also minimize the side effects of the drug, for example, the side effects of APIs used to treat diabetes can be reduced by introducing a long-acting injectable formulation.

Image Credit: onair/Shutterstock.com

What technology platforms and processes does Innocore use to develop its long-acting injectables?

We use a range of platforms to produce a formulation with microparticles, solid implants, drug-eluting coating or injectable gels.

We use the SynBiosis Multi-block Copolymer platform and the In-Gel Tri-Block Co-polymers to develop long-acting injectables and saw great success in the development of solid implants using SynBiosis polymer and hot-melt extrusion.

In terms of business model, a client or partner provides the API application, and we contribute our drug delivery system. We work with the partners from the initial feasibility study to GMP manufacturing and supply for phases one and two of the clinical studies.

Once the project reaches listed manufacturing for clinical trial and commercial manufacturing, we hand this back to a designated panel or selected CMO.

Could you expand a little on Innocore’s long-acting injectable solid implant and where it fits into the existing market?

Several long-acting non-biodegradable injectable implants are already available on the market, including Norplant™, Levoplant™, Implanon™, and Jadelle™. These are large implants with high amounts of active ingredients that offer long-term efficacy – around 3 to 5 years.

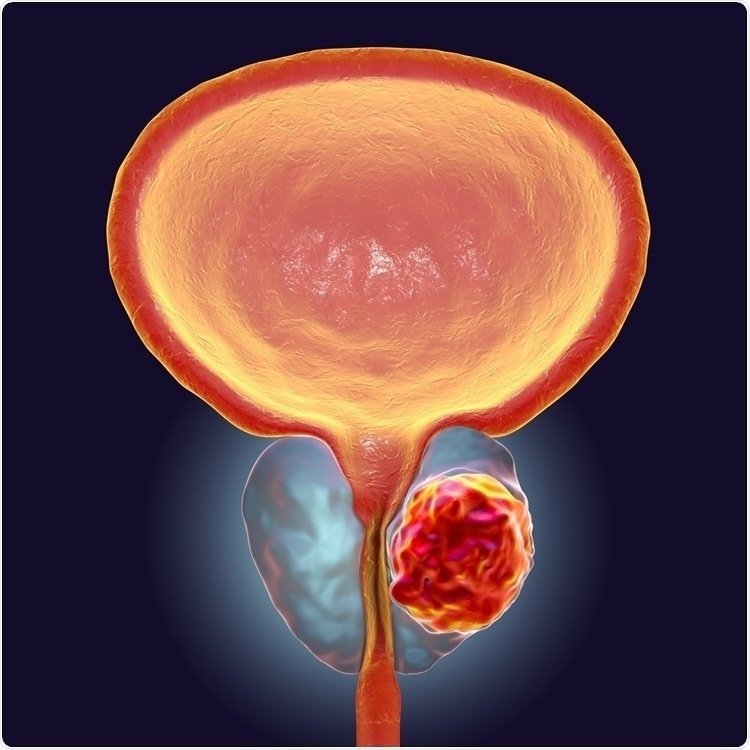

Specific non-biodegradable implants are used in the treatment of prostate cancer, such as AstraZeneca’s Zoladex™ which contains goserelin.

Innocore has developed a long-acting injectable solid implant using hot-melt extrusion, as both the monolithic matrix and the form of the implant with the release controlling layer.

Before developing the monolithic matrix, we use small MiniLab extruders ideal for small-scale early development - around 5 to 7 grams of material. After, we can scale up to manufacturing at a clinical supply or commercial scale.

In principle, we need to compound or blend the polymer and API and melt and mix the components in a hot melt extruder. Next, we create an implant stick using a rod-die before pulling out the material and cutting it into implants.

Implants are often formed as cylindrical rods, but we also cut them into thin sheets.

How has your experience in developing long-acting injectable implants been beneficial when working with products like Zoladex?

We have a great deal of experience in the deployment of generic formulation for products like Zoladex.

The implants for each of these two strengths have different dimensions and require delivery by two different sized injectors - the 15 gauge needle for one-month treatment and the 14 gauge needle for 3-month treatment.

To improve treatment delivery, we developed and evaluated the generic goserelin implant product, Implagres. We developed the implant formulation and compared drug release characteristics via individual release experience experiments.

We confirmed that the release profile of the 1 month sustained release formulation is typical of a PLGA polymer matrix - non-linear and biphasic in the first week exhibiting a slow release from day 0 to 7. Once the polymer starts degrading, the release rate increases from day 7 to 21.

By day 21, most of the implant’s drug content was released. We saw another decrease in the release rate when API sources inside the implant ran low.

We compared the originator with our generic implant in vivo to characterize pharmacokinetic and pharmacodynamic properties - the API efficacy. Regarding release profiles, the generic implant and originator implant were almost identical.

When examining pharmacokinetics in vivo, we also noticed that plasma concentration of goserelin from day 7 to 21 increased significantly.

We concluded that increased goserelin concentration is linked to the polymer liquidation phase.

Image Credit: Kateryna Kon/Shutterstock.com

Is it possible to develop formulations that last longer than 3 months?

We theorized that a longer-acting implant to reduce the administration frequency could be achieved by increasing the amount of API to increase treatment duration.

We determined via a linear calculation that a 4-month or 6-month duration would be needed to deliver 14.6 milligrams or 21.6 milligrams of goserelin, respectively. With that amount, we would need a bigger implant.

A 1-month implant has a 1.2 mm diameter and 10 mm length. To increase the duration to 3 months, a larger 1.5 mm diameter and 15 mm length implant would be needed – and even larger for 4- and 6-month treatments.

A 1.5 mm diameter implant cannot be easily injected into the body – and requires delivery under anesthesia, but this still offers the opportunity to deliver a longer sustained release of goserelin while maintaining patient affordability.

Are there any disadvantages to using the PLGA co-polymer for long-acting injectables?

The disadvantages of the PLGA co-polymer primarily stemmed from its irregular biphasic release kinetics with the spike in plasma drug concentration, which was not needed to maintain drug efficacy.

This highlights the need for alternative biodegradable polymers suitable for the development of long-acting injectable implants with more consistent release profiles.

Could you give an overview of Innocore’s development of biodegradable polymers?

We developed a new type of biodegradable polymer – the SynBiosis polymer, a hydrophilic biodegradable poly(etherester) urethane polymer composed of well-known monomers like epsilon caprolactone, dioxanone, lactide or glycolite. It uses well-known compounds like polyethyleneglycol and butanediol as initiators, tin octanoate as a catalyst, and butane diisocyanate as a chain extender.

SynBiosis is a multi-block co-polymer with phase-separated morphology. There are two different phases of the polymer – the hydrophilic amorphous domain and the hydrophobic crystalline domain.

A characteristic of the SynBiosis polymer distinguishing it from the conventional PLGA polymer is the acidic liquidation product does not accumulate in situ. The polymer swells and the liquidation product diffuses through the hydrophilic amorphous domain.

The SynBiosis polymer is highly biocompatible, and all degradation products have been safety tested and evaluated in vitro and in vivo using animal models. We also share ISO-10993 biocompatibility and toxicity data package with partners during development.

Is the SynBiosis polymer customizable?

The SynBiosis polymer is highly customizable and can be easily adapted to meet the needs of sustained-release delivery.

We can control the degree of swelling or liquidation rate of the polymer, allowing delivery at different release rates and release profiles by adjusting the ratio between the hydrophilic block and hydrophobic crystalline blocks.

We can also finetune the polymer by adjusting the pulyethylene glycol molecular weight, polyethane glycol content percentage, monomer type, monomer fraction, block ratio, and multi-block co-polymer molecular weight.

The increase in goserelin serum corresponded to PLGA polymer matrix degradation between days 7 and 21, and that liquidation caused an unnecessary increase in goserelin concentration in plasma, maintaining the drug’s efficacy.

We could reduce the dose using a different release mechanism, so we developed a 4-month sustained release goserelin implant using our SynBiosis polymer-based formulation.

Using the SynBiosis polymer, the API's release is more regular than the PLGA metric.

We calculated the implant’s daily drug release using 10.8 milligrams of API, noting that while the 1-month and 3-month formulation exhibited a spike in goserelin daily release, the SynBiosis-based formulation resulted in regular, constant direct goserelin release for 4 months using the same amount of API and without increasing implant size.

Is it possible to control the API release via other structures or mechanisms?

We saw good results in goserelin implant deployment using a monolithic structure, but in some instances, a two-layer product providing an additional release control mechanism was needed.

We developed a dual-layer implant using co-extrusion processes, but in some applications, there was an incompatibility between the core and membrane polymers because of the liquidation temperature of the API or the polymer.

To address this, we used a wire coating process to produce a dual-layer structure..

This process involved an 11 mm extruder coupled with a wire coating dye. The core material is introduced, and the extrusion process occurs on a conveyor belt. Laser control measures and maintains the appropriate implant diameter and coating layer.

The process results in cylindrical tubing with a coated layer and is cut to the desired length.

Image Credit: Akkalak Aiempradit/Shutterstock.com

Can SynBiosis be used to develop long-acting, reversible implants?

Yes, we are currently developing long-acting reversible contraceptive implants that require no surgical removal. This reduces the need for local anesthesia by decreasing the diameter of the implant.

We are also developing a contraceptive in microneedle form, which will allow virtually painless administration. This product must ensure that the API or the hormone in the plasma can maintain efficacy for around 6 months.

After releasing all of the drug, its plasma concentration should drop rapidly, allowing the patient to return to fertility should they wish. At this point, the implant biodegrades.

We developed the SynBiosis multi-block co-polymer-based implant for use with goserelin, but the platform is suitable for a range of APIs which are sensitive to temperature or a decrease in the local pH.

Using a SynBiosis multi-block co-polymer allows extrusion processes to run at temperatures as low as 50- 60 °C, protecting heat-sensitive APIs, like those found in contraceptive implants.

SynBiosis’ beneficial integrity allows for controlled protein release characteristics when using different polymer structures. Each API needs to be accommodated using a different polymer, but this allowed us to specifically design the polymer structure to be suitable for use with long-acting contraceptive implants.

About Thermo Fisher Scientific – Materials & Structural Analysis

Thermo Fisher Materials and Structural Analysis products give you outstanding capabilities in materials science research and development. Driving innovation and productivity, their portfolio of scientific instruments enables the design, characterization, and lab-to-production scale of materials used throughout the industry.

Thermo Fisher Materials and Structural Analysis products give you outstanding capabilities in materials science research and development. Driving innovation and productivity, their portfolio of scientific instruments enables the design, characterization, and lab-to-production scale of materials used throughout the industry.

X-ray fluorescence spectrometers, FTIR spectrometers and X-ray photoelectron spectrometers enable researchers and material analysts to probe the chemical composition of materials ranging from ultra thin-films to bulk powders used in product development and materials troubleshooting. We offer a line of rheometry and viscometry instruments, as well as single- and twin-screw extruders, for laboratory benches that enable you to measure the physical property of semi-solids and liquids for shear flow and yield stress.

No other company offers the breadth of products and the depth of analytical capabilities for materials science and engineering.

Extruders & Torque Rheometers

Ideal for materials compounding experiments and pilot scale extrusion production, our minicompounders and 11mm parallel twin-screw extruders, and torque rheometers are well-suited for research and development in the polymer, pharmaceutical, bioscience, and nanotechnology sectors.

Rheology & Viscometry

Thermo Scientific rheometers and viscometers are designed to accurately measure the properties of fluids and other complex materials. They are recognized for accuracy and ease of use in quality control, product development, and research applications. Our viscometers allow you to quickly determine the flow behavior of fluids and are designed for your application.

Vibrational Spectroscopy

Our line of Nicolet FTIR spectrometers have led the analytical instrument industry for over fifty years with reliable, robust and flexible solutions. Thermo Scientific Raman spectrometers enable point analysis, confocal microscopy and chemical imaging.