Can you explain how Bartels Mikrotechnik’s experience benefits clients looking for a fast entry into microfluidic applications?

Bartels Mikrotechnik has over 26 years of experience in the microfluidics industry. During this time, we have done everything from using existing components in building systems for our clients to over-adapting them and creating our own products. This has given us an insight into the industry and technologies.

Today, we have our own in-house production and an engineering team that works on new microfluidics approaches. Thanks to our extensive partner network, we can offer our clients full systems with many possible applications. We support our customers at every step – from the first idea to the final product.

What is the “Microfluidic SolutionMaker” approach?

We offer a complete, application-oriented, adaptable liquid handling system. We use our own and partner components to build a complete system. Additionally, we identify the problem and develop an application-oriented solution. Finally, our systems are adaptable and allow maximum flexibility due to the modular set-up.

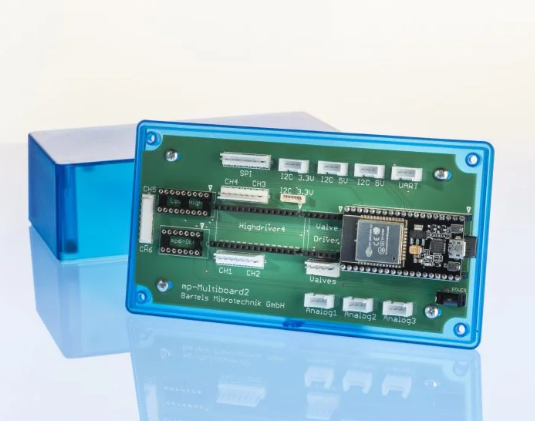

All the components that we are selling are connected to our mp-Multiboard2 electronic. That way, the user has one software interface to control the system. Bartels Mikrotechnik uses existing components to build fully functional systems fast. We are the microfluidic SolutionMaker.

Image Credit: Bartels Mikrotechnik GmbH

How does this approach differ from some of Bartels Mikrotechnik’s industry rivals?

One of our biggest advantages is that we can seamlessly incorporate components from different suppliers into our systems. We have an extensive network that we work in close partnership with. All components are thoroughly tested and then integrated into our system, to be controlled with one software. That makes it easier for our clients to add new functions to their systems.

Additionally, if we realize that the perfect component for an application does not exist yet, we have a whole engineering team to work on developing one. That is how the mp-bt bubble trap was created.

What is cell analysis and sorting, and how is it used?

In cell analysis, individual cells are made visible by microfluidics and evaluation units, mostly radiation, optics, etc. These cells are then analyzed in individual cases; thus, personalized medicine becomes possible. For example, bone cancer differs between patients, and chemotherapy can be adapted through cell analysis to fulfill specific requirements.

Cell sorting is the homogenization of cell mixtures for multiple research, diagnostics, and therapy applications.

Can you explain the role that droplet generation plays in this area?

In microfluidics, droplet generation is an essential but highly complex topic. The goal is to create droplets of a specific size depending on the application. Droplet generation in microfluidics is based on the use of two immiscible phases. These are the continuous phase (oil, the medium in which droplets flow) and the dispersed phase (water, the droplet).

Often, droplet generation is a technology that is necessary to sort and analyze cells properly.

Can you explain what Bartels Mikrotechnik micropumps are and how they are used?

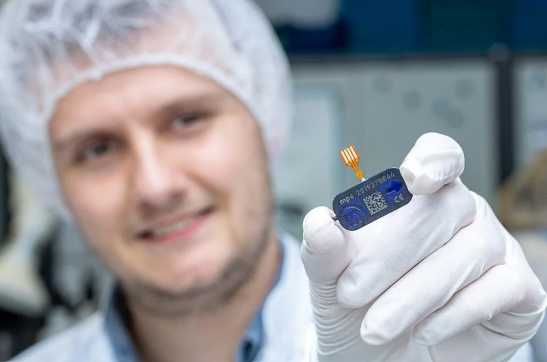

The micropumps in Bartels’ mp6 series are miniaturized double diaphragm pumps. Two piezo actuators run each micropump. Due to the space and energy-saving construction, they are cost-effective even in high quantities.

The materials used make the micropumps remarkably versatile. Variable flow rate adjustment guarantees a wide range of possible applications. The mp6 micropumps can promote liquids, gases, and mixtures.

Mp6 micropumps are used in life science, diagnostic, medical and Point-of-Care testing applications. Additionally, you can use our micropump for industrial applications like process control or gas detection.

Image Credit: Bartels Mikrotechnik GmbH

What sets Bartels Mikrotechnik micropumps apart from similar technology?

The mp6 micropumps are very small and lightweight. Therefore, they are easily integrated even into handheld devices. They can also promote liquids and gases, and one can easily switch between both.

Since we are the producer of the pump, we can also offer our customers a competitive price. Additionally, we can provide high quantities even on short notice.

How is point-of-care microfluidic testing used, and what advantages are there to this pathogen detection?

Particularly exciting for the field of microfluidics is the Point-of-Care testing for pathogens such as MRSA or COVID-19. Here, various possibilities exist to perform these tests quickly and thoroughly without sending samples to central laboratories.

In addition, the system can also be efficiently and cost-effectively converted to other viruses or germs. Thus, switching between COVID-19 and MRSA is feasible.

A major advantage over simple, rapid tests is that the viral load can also be determined. Thus, it can test whether antigens are present and in what quantity. Antibodies can also be tested; thus, an unrecognized and survived disease or immune status can be visualized and quantitatively classified.

How has the use of such systems changed in the wake of the COVID pandemic?

One significant change is that Point-of-Care systems are now more widely recognized. Since Covid started, almost everyone has learned about different types of Point-of-Care and laboratory testing. This has increased the importance of this topic in society in general.

Simultaneously, the need for POC devices skyrocketed, and many labs had to expand their resources and testing capabilities. This benefited their suppliers.

Image Credit: Bartels Mikrotechnik GmbH

How are VOC sensors used to identify liquids?

In an industrial setting, one of many reasons for the presence of VOC in the air can be leakages. For example, the leakage of coolant, like the widely-used hydrofluorocarbons (HFC), can have very harmful effects. HFC are potent greenhouse gases and dangerous to the environment. You can use air quality measuring systems to ensure safety in industrial workplaces.

Alternatively, you can convey gas samples to sensor units to monitor VOC concentration. This form of VOC detection can also be applied in production lines for process control or exhaust gases in the automotive industry.

Every liquid evaporates, which is something that VOC sensors can detect. For instance, it is possible to measure the ethanol level in a liquid during a fermentation process by measuring the gas phase above because the ethanol level above a liquid depends on the ethanol level within it.

To build a VOC detection system, the user can easily combine our active microfluidic components. The mp6 micropump actively conveys air samples to a VOC sensor, after which the sensor measures the amount of VOC in the sample. This reading can be easily monitored in our software. Since the mp6 actively moves air to the sensor, this allows for a more exact reading than passive systems.

What advantages are offered through the testing of air above a liquid rather than the liquid itself?

By probing the evaporation above the sample, the risk of contamination is decreased as there is no direct contact with the reagent or sample. As a result, there is less emphasis on using compatible materials, and the user does not even have to clean the system before moving to the next sample. This saves time and money.

There is also no loss of the reagent or sample, as it is not necessary to feed a reagent through a system for measuring. Instead, the evaporation above it can be used, which would have otherwise gone to waste.

What industries will benefit the most from this product?

Several processes and quality controls can benefit from this approach. Our primary industries would be pharma and food & beverage, but the same system can easily be adapted to pretty much any application.

About Florian Siemenroth

Florian Siemenroth has studied Nano Engineering and Mechanical Engineering. After working several years in R&D as part of the microEngineering team at Bartels Mikrotechnik, he is now responsible for the product management in the microComponents division.

About Bartels Mikrotechnik GmbH

For more than 25 years, Bartels Mikrotechnik has been a globally active manufacturer and development service provider in microfluidics. Together with our partners, we help our customers find the right microfluidic solution for their applications.

A microfluidic SolutionMaker, Bartels offers a complete, application-oriented, modular liquid handling system. With our evaluation sets and the mpSmart, the user can test our mp6 micropump directly in their application with everything pre-prepared. We also have an extensive partner network that enables us to offer high-quality, tested components to complement a microfluidic system.

Our microComponents business unit offers a wide range of microfluidic components. Bartels Mikrotechnik manufactures and distributes microfluidic products – especially for miniaturized and portable applications. Our key products are micropumps that pump small volumes of gases and liquids. They are used in various ways in biotechnology, pharmaceuticals, and medical technology.

In microEngineering, our team constantly works on new solutions for new markets. We allow new components to mature to the patent stage and work on the transition from individual applications to series production. Our goal is to create complete product worlds for a global market.