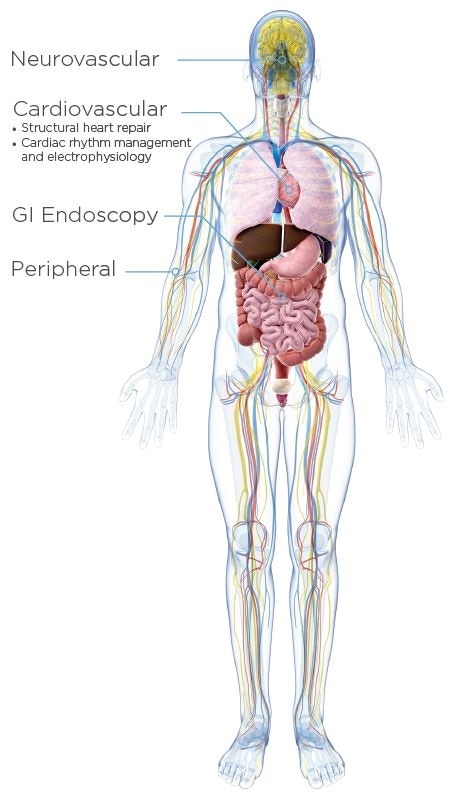

Focusing on the Medical Market

Zeus makes cutting-edge polymer parts for medical devices designed for minimally invasive medicine. These core products are built to deliver better performance with improved manufacturing ease.

Starting with the selection of the material up to the customized design of the polymer part, the aim of the Zeus team is to achieve access to the required body part with exactness. The scientists and polymer specialists at Zeus work with the medical experts to arrive at solutions that have better strength and safety so that patient outcome is improved and patient care occurs at a higher level.

Zeus products are biocompatible, and have outstanding material characteristics. These allow medical devices to be innovated from the level of dreams to reality.

Various Components of Catheters

Sophisticated Extrusion Processes

Zeus has the capability to choose materials as well as to build extruded polymer device components with very low tolerances and advanced engineering design. This helps the clinician to visualize and treat lesions in the most difficult anatomical locations, with high levels of predictability and accuracy. This is essential to the final guarantee that a procedure is very likely to succeed as planned.

Some important extruded polymer medical applications include:

- Fusing sleeves

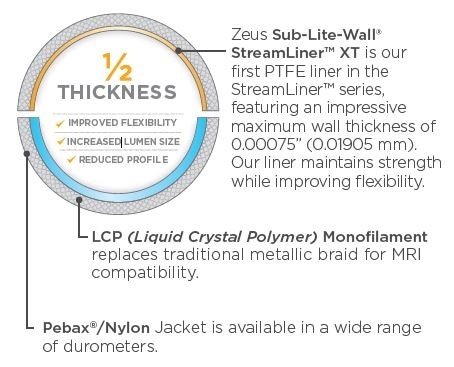

- Liners for catheters

- Materials that form jackets for various components

- Braids of non-metallic materials

- Coverings for wire guides

- Protectors for various stents and balloons

- Sheaths for introducers

- Tubing for multi-lumen catheters

- Processing / support mandrels

- Specially manufactured tubings

- Support with R&D

- Programs to support prototype sampling

This PTFE mandrel is designed to give support to the inside diameter of the catheter while it is being built and is removed immediately afterward.

Zeus offers customers two different options to achieve reflow of the jacket. The first option is that the FEP heat shrink is used to reflow the Pebax®/Nylon jacket over the underlying braiding, to form the catheter shaft, following which the heat shrink is removed. The other option is that the peelable heat shrink called FluoroPEELZ® is used, which makes it easier to remove the heat shrink after recovery is completed.

Implants

1. ABSORV® Bioabsorbable Extrusions

These are characterized by finite functionality in addition to absorption features which can be tailored to requirements.

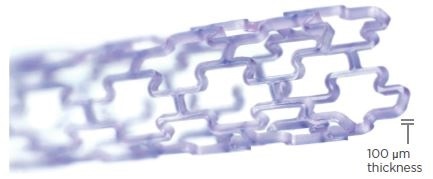

2. BIOWEB® Encapsulated Stent Technology

This stent imitates the natural extracellular matrix found within the body, forming a novel type of encapsulated stent.

3. AEOS® ePTFE Microporous Products

- This line of products has a microporous structure into which cells can grow.

- Its density and pore size can be tailored to precision, to allow selective permeability.

- The microporous structure can be used for all kinds of devices including monofilament sutures, tubing, ribbons, multi-lumen catheters, membranes and other monofilaments.

Value Addition or Secondary Benefits

The use of Zeus extruded polymer components is associated with the following capabilities:

- Skiving

- Pad printing

- Flanging

- Drilling or punching

- Scoring

- Overmolding

- Slitting

- Flaring

- Heat sealing

- Draw down

Zeus has an exchange panel to facilitate interchange of ideas on extruded polymer technology and products between client and manufacturer. The Zeus sample locker, meanwhile, offers an easy, speedy and no-cost method of ordering the most sophisticated samples of tubing, heat shrinks and extrusions for building prototypes.

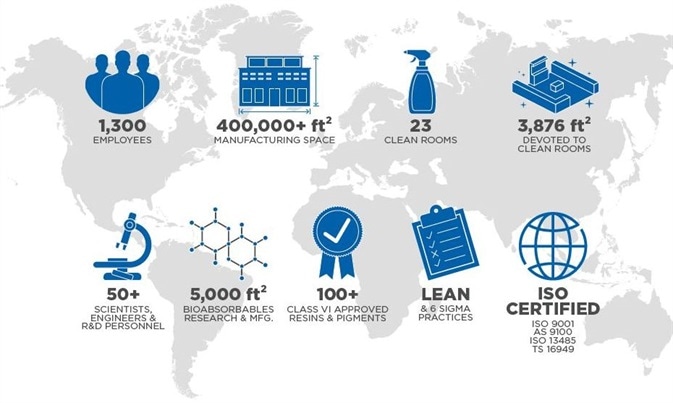

About Zeus Inc.

Zeus were among the first to work in the arena of minimally invasive techniques for revolutionary procedures such as neuromodulation. Their PEEK drawn fiber offers a non-metallic replacement for stainless steel. And when a major aircraft manufacturer needed an immediate design change on a harness assembly, Zeus delivered in record time.

Zeus has vast experience in medicine, aerospace, energy exploration, automotive, fiber optics and more allowing you to leap past “can’t” and into “how”.

What makes them different is that they think differently. Even though they’re the world’s leading expert in polymer tubing, they’re much more than a polymer tubing company. Zeus solves problems and anticipates innovation. Zeus are in the business of changing lives.

History of Zeus Inc

Frank P. Tourville, Sr. worked in the polymer extrusion industry for ten years before creating Zeus from a desire to “do it better.” While Zeus quickly established itself as a world leader providing high-performance polymer extrusions and solutions, their rapid, sustained growth is rooted in a commitment to improving industries and lives.

Zeus is Everywhere You Are

Zeus touches just about every major industry in the world. Their products make everyday life better, faster, safer. You’ll find Zeus technology in your backyard grill and automobile. You’ll find them in the aircraft taking you where you need to go and the hand of the surgeon saving your life. Zeus' research facilities are surpassed only by the enthusiasm and commitment of our people.

Why Choose Zeus As An Innovation Partner?

When your product and reputation are on the line, you want the best. No other company in the world delivers the consistency, dependability and unrivaled innovation of Zeus.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.