The challenge

3D bioprinting is a developing field in regenerative medicine where the goal is to create cell-laden, three-dimensional structures to imitate bodily tissues. This holds a vital position not just in tissue engineering, but also in drug discovery, drug delivery and cancer studies.

However, the critical constraint is the development of an ideal bioink; i.e. one that allows the geometrical precision of the printed constructs, mechanical stability after printing, as well as lasting cell viability.

The solution

PeptiGeIs®, synthetic, chemically defined peptide hydrogels, have shear thinning properties, which means they can be printed and injected and regain their structural integrity directly following shear removal. PeptiGels® also have tunable mechanical properties, do not require chemical or physical post processing post printing and they are especially adept at encouraging cell attachment, differentiation and proliferation.

The science

Using PeptiGeIs® of different stiffness, Dr. Marco Domingos and colleagues from The University of Manchester have printed cell laden constructs. They have explored and optimized the boundaries of the printing process, specifically extrusion pressure, nozzle diameter and valve opening time, prior to exploring the system’s ability to print cell laden constructs of mammary epithelial cells using PeptiGels® with alterable stiffness. Any effect of the shear stresses brought about by the extrusion-based pressure on the cell viability was explored through live/dead assays over a one week period in cell culture.

PeptiGels® offer excellent compromise between the physicochemical (rheological) and biological properties of the printed structure to ensure it retains its structural integrity in addition to a high cell viability.

Dr Marco Domingos, Senior Lecturer, The University of Manchester

The results

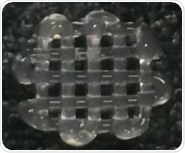

Employing PeptiGels® and a commercially available extrusion bioprinter (Figure), complex structures loaded with mammalian epithelial cells were printed successfully. Results demonstrated it was possible to print structures with a high structural integrity and geometrical/dimensional precision of the printed cell laden constructs. The printed samples were then cultured for a week following which the amount of viable cells stayed high and had begun to proliferate for all stiffnesses of PeptiGel®. This verified that the conditions the epithelial cells were exposed to were not harmful to their health and thus PeptiGels®, illustrating the viability of the system to print 3D tissues and matrices.

Image Credit: Manchester BIOGEL

The future

PeptiGels® have been successful in demonstrating their ability to provide enhanced printability and cell viability, emphasizing how suitable they are to be used as a bioink for 3D bioprinting.

About Manchester BIOGEL

Over 15 years ago, Professors Aline Miller and Alberto Saiani at The University of Manchester synthesised a self-assembling oligo-peptide with interesting gelation properties. This work started with a small grant from the University.

Over subsequent years, the team meticulously crafted and studied self-assembling peptides to perfect their platform technology and produce a range of hydrogels ideal for 3D cell culture. In 2014, due to a demand for their materials, our company, Manchester BIOGEL was founded to enable these hydrogels to be readily available to researchers wishing to create new opportunities in the high-growth fields of 3D cell culture, 3D bioprinting and medical devices. Since opening our doors, we have supported scientists in the UK and beyond to create optimal environments for a wide variety of cell types.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.