Pulsed-field gel electrophoresis (PFGE), or clamped homogeneous electrical field electrophoresis (CHEF), is a novel gel electrophoresis type for the separation of DNA macromolecules.

This is accomplished by alternating anode and cathode at specific intervals, which means that the DNA molecules have to realign themselves in the electrical field before they can continue to progress in the matrix.

Smaller molecules orient themselves much faster than larger ones, which means that they cover a larger distance in a predetermined amount of time. The separation of the DNA molecules relies on a series of various factors: voltage, runtime, buffer concentration, temperature and how fast anode and cathode are changing.

Due to the extended runtimes of PFGE protocols and the occasional high voltage, a constant and low buffer temperature is key for the success of the method. These low temperatures and long runtimes present a unique challenge for the tubes used in a PFGE setup for the transmission of the buffer solution.

Objective: Comparison of Three Tubes in Combination with a Peristaltic Pump for Buffer Recirculation in Pulsed-Field Gel Electrophoresis (PFGE)

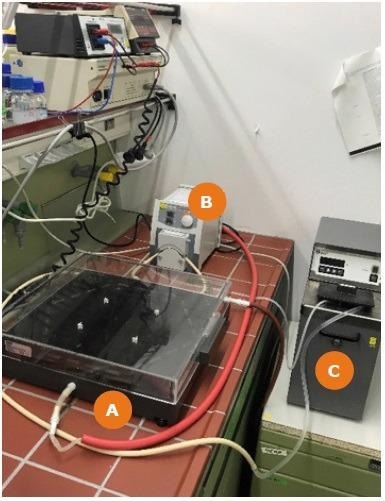

Often, standard silicone tubes are employed when running a PFGE setup, as illustrated in Fig. 1. A pump (Heidolph Hei-FLOW Value 01 peristaltic pump with SP quick 1,6 pump head; B) is affixed to the running chamber (A; Fig. 2) with about 10 m of tube material fed into a cooling unit (C).

Figure 1. Setup of the PFGE apparatus. (A) shows the gel chamber in which the running buffer is located. This buffer is continuously circulated by a pump (B). About 10 meters of silicone tubing are placed in a cooling unit (C) to keep the buffer constant at low temperature. Image Credit: Heidolph North America

Figure 2. Top view on the gel chamber, the flow direction of the buffer solution is indicated by the red arrow. Image Credit: Heidolph North America

Since the apparatus is continually used with cold buffer for up to 260 hours, it is critical to choose the appropriate tubing to avoid any complications (tearing, formation of air bubbles and loss of pumping power).

Silicone tubes wear out very fast. Therefore this test will show if they can be replaced with a more robust one.

Comparison of three tubes for peristaltic pumps will be carried out with regards to their applicability in the field of PFGE. Those tested were Heidolph’s Tygon® Standard, Tygon® 2001 and PharMed® tubes with an inner diameter of 6,4 mm and a wall thickness of 1,6 mm.

Method and Results: A/B Protocols of PFGE and Evaluation of the Three Tubes

The following tests have been conducted at the laboratory of Dr. Marlis Dahl, Department of Biology, Division of Biochemistry at the Friedrich-Alexander-University Erlangen-Nuremberg.

The tubing was tested in the assembly as exhibited in figures 3 and 4, in line with the protocols shown in Table 1: Protocol A was selected due to it being the most commonly used protocol in the laboratory; Protocol B was used because it has the greatest requirement regarding the runtime.

Figure 3. Experimental setup of the PFGE apparatus, showing in which direction the buffer flows (red arrow) inside of the chamber and which tubes transport the buffer to (blue arrow) and from the cooling system (yellow arrow). Image Credit: Heidolph North America

Figure 4. The connected pump with the PharMed® tubing. Also shown is the flow or pump direction of the running buffer. Image Credit: Heidolph North America

Table 1. Test protocols for the examination of the tubes. Source: Heidolph North America

| Parameters |

Protocol A |

Protocol B |

| Buffer |

0.5 × TBE buffer

(2 l) |

0.75 × TBE buffer

(2 l, changed every 48 h) |

| Buffer temperature |

12°C |

8°C |

| Set temperature of cooling device |

9°C |

4 °C |

| Voltage in the gel chamber |

200 V (6 V / cm) |

50 V (1.5 V / cm) |

| Pole changes (as gradient) |

between 40 sec and 80 sec |

between 1200 sec and 4800 sec |

| Set pumping speed |

40 rpm |

40 rpm |

| Running time |

24 hrs |

260 hrs |

After the protocols, the tubing was evaluated and it was decided if any changes were necessary.

The Tygon® 2001 tubing turned out unsuitable for the intended purpose due to it being too rigid.

Already demonstrating undesirable effects in the shorter test following Protocol A: although bubble accumulation was mitigated during the day, the next morning, numerous large bubbles were found to impede pumping (that is, insufficient cooling of the gel).

Moreover, the tube appeared to be rather brittle in the area inside the pump head. The Tygon® Standard tubing facilitated good buffer circulation for a slightly longer period of time, but after some use, it cracked.

This could be a result of the low temperature of the buffer, which makes the tubing less flexible and eventually leads to breakage. The PharMed® tubing performed best.

Although the part of the tubing inside the pump head stretched after an extended period of use, demonstrating that the material was thinning, it still lasts much longer than a common silicone tubing.

The latter can be fitted in the same way, but wear is significantly greater, which means that the part of the tube inside the pump head must regularly move. Otherwise, tearing will occur.

Conclusion: Heidolph’s Pharmed® Tubing with Hei-FLOW Value 01 Meets the Challenge

These tests demonstrated that replacing conventional silicone tubing can be achieved with the longer lasting PharMed® tubing for a pulsed-field gel electrophoresis assembly using the Hei-FLOW Value 01 peristaltic pump with the SP quick 1.6 pump head.

The Tygon® 2001 and Tygon® Standard tubing were proven to be inappropriate for the PFGE process.

Image Credit: Heidolph North America

This information has been sourced, reviewed and adapted from materials provided by Heidolph North America.

For more information on this source, please visit Heidolph North America.