Sheaumann has successfully designed and developed the world’s first commercially available diode-laser-pumped continuously operating (CW) 1.5 W, 2.94 µm Er:YAG laser.

Image Credit: Sheaumann Laser, Inc.

This laser functions using the end-pumped microlaser chip configuration first documented by Chen et al.1 This configuration was later extended to incorporate other Er3+-doped garnets by Dinerman and Moulton.2

The development of power diode pump laser sources that demonstrate extended life and higher brightness have resulted in this novel technology becoming commercially feasible.

The energy level dynamics of a typical laser mean that the use of a high brightness pumping source is vital. Figure 1 features an energy level diagram illustrating the 6.4 ms lifetime of a lower laser level (4I13/2) which is notably longer than the 0.1 ms lifetime of an upper laser level (4I11/2). Under normal circumstances, this difference would lead to self-saturation.

A simplified energy level diagram (reproduced from Georgescu and Toma4) for Er:YAG highlights pump absorption and laser transitions, with cooperative upconversion between pairs of Er3+ ions offering greater than unity quantum efficiency. This approach also addresses bottlenecking issues in the 4I13/2 lower laser level.

![A simplified energy level diagram for Er:YAG showing the pump absorption and laser transitions. Cooperative upconversion between pairs of Er3+ ions provides greater than unity quantum efficiency and overcomes bottlenecking in the 4I13/2 lower laser level. This diagram was reproduced from Georgescu and Toma [4].](https://www.news-medical.net/image-handler/picture/2021/8/2ImageForArticle_20570_4439227517524317248.jpg)

Figure 1. A simplified energy level diagram for Er:YAG showing the pump absorption and laser transitions. Cooperative upconversion between pairs of Er3+ ions provides greater than unity quantum efficiency and overcomes bottlenecking in the 4I13/2 lower laser level. This diagram was reproduced from Georgescu and Toma4. Image Credit: Sheaumann Laser, Inc.

At high Er3+ concentrations and under intense pumping, cooperative upconversion between neighboring Er3+ ions can be observed depleting the 4I13/2 level of one ion while simultaneously supplying a pumping path to the upper laser level via the 4I9/2 energy level (Figure 1, column (a)).

This effect prevents self-termination of the laser while providing almost two photons at the laser wavelength for every individual absorbed pump photon population – leading to greater than unity quantum efficiency.1,3,4

A combination of upconversion from the 4I11/2 energy level (Figure 1, column (b)) and cross-relaxation from the 4S3/2 energy level (Figure 1, column (c)) has been determined as having an effect on 2.94 µm Er:YAG laser dynamics.4

Flashlamp-pumped 2.94 µm Er:YAG and Er:YSGG lasers are typically utilized in dental procedures working with hard and soft tissue. Attention has also been given to the potential application of lower energy quasi-cw diode-laser-pumped devices in an array of micro-surgical applications.5

This article investigates a 1.0 W cw 2.94 µm Er:YAG laser’s performance and quasi-cw characteristics – in particular, Sheaumann’s MIR-Pac laser. The laser’s current incarnation is able to function as an OPO pumping source, offering excellent potential for use in soft tissue micro-surgical applications and a range of other application areas; for example, spectroscopy.

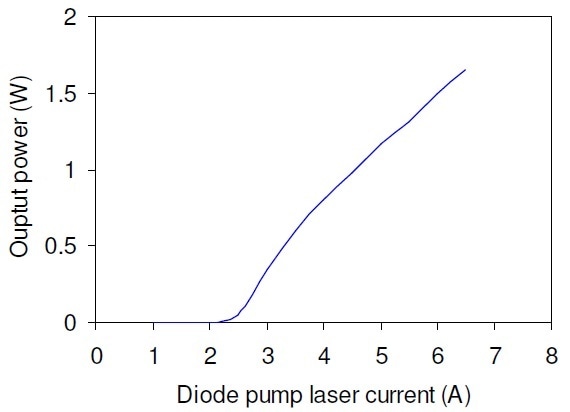

Figure 2. CW output power of a 2.94 μm MIR-Pac laser versus the diode pump laser drive current. Image Credit: Sheaumann Laser, Inc.

CW laser performance

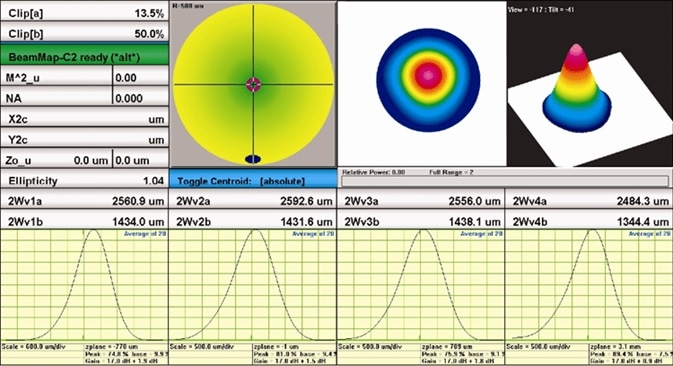

When functioning in cw operating mode, the MIR-Pac laser is specified for use at a maximum of 1.0 W of output power (Figure 2) in an M2<1.2. This includes a TEM00 mode beam (Figure 3) which exhibits a standard beam divergence of 17 mrad.

Advances in laser technology have recently enabled the generation of up 1.5 W output power, though this has been hindered by the onset of thermal rollover - believed to be linked to thermal lensing occurring in the microlaser chip.

Research is underway into the potential for a short laser resonator to independently control resonator stability and mode size. This approach could be used to enable efficient operation at higher output powers.

Figure 3. Typical TEM00 output beam data for the 2.94 μm MIR-Pac laser. Image Credit: Sheaumann Laser, Inc.

Quasi-CW laser performance

The 2.94 µm Er:YAG laser is optically pumped using a diode laser, which can be pulsed or operated continuously via specific drive current waveforms.

Using a rectangular current pulse to drive the diode laser with rise times of <10 µs will result in the corresponding optical pump pulse efficiently generating a population inversion exceeding the lasing threshold.

It is also possible to generate nominally rectangular laser pulses possessing durations from <0.1 ms to a large fraction of a second – a process referred to as quasi-cw operation because the pulse durations are of sufficient length for the laser output to achieve a steady-state.

This mode of operation allows the laser to be operated at peak powers. These powers are proportionally higher than the average laser power operating limit by a factor that is the inverse of the duty cycle of the quasi-cw laser pulse train.

Usage of this technique is currently limited by the maximum peak power of the diode pump laser - approximately 10 W. It is anticipated that this will increase in line with the introduction of the next generation device.

Meister et al.5 were able to showcase the generation of 15.7 mJ in 2.5 ms pulses from a quasi-cw diode-laser-pumped Er:YSGG laser designed to be utilized in soft tissue microsurgical applications. This demonstrates good agreement with Sheaumann’s 6 mJ in 2.5 ms data, shown below.

Meister et al. also offer a comprehensive review of a number of other quasi-cw diode-laser-pumped 3-micron Er-lasers able to generate 30 mJ energies, but these had not been enhanced to enable efficient operation at lower pulse energies. These lasers were deemed not cost-effective because of their use of stacked arrays of diode laser bars.

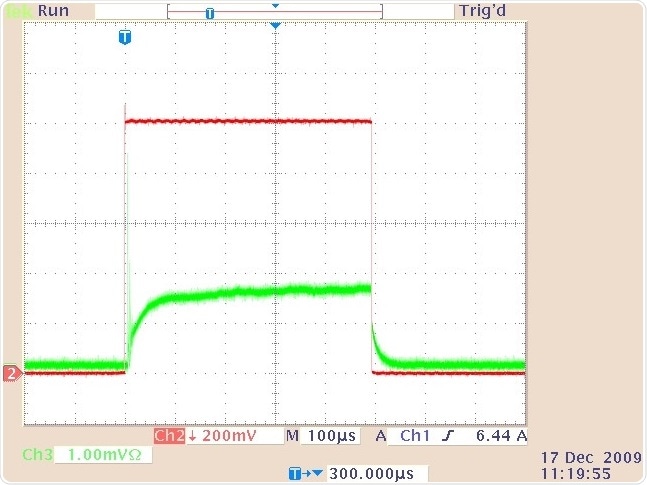

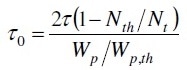

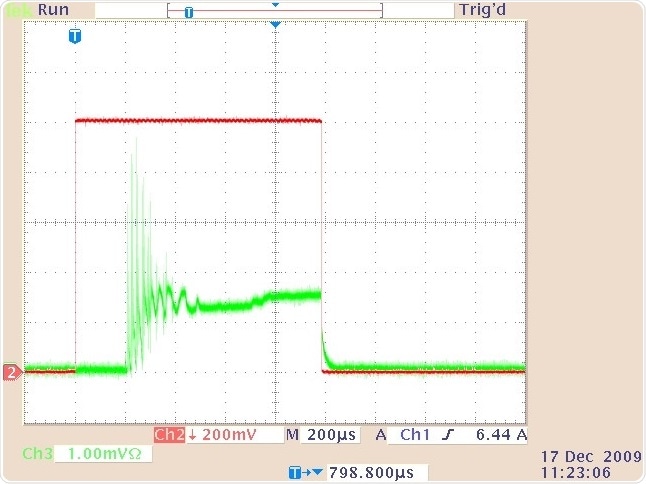

Figure 4. The quasi-cw laser output (lower trace) and drive current waveform (upper trace) for a 0.5 ms duration, 10 A current pulse at a 1000 Hz repetition rate. Image Credit: Sheaumann Laser, Inc.

Figure 4 shows a standard quasi-cw Er:YAG laser pulse generated via pumping with a 0.5 ms diode laser pulse at a repetition rate of 1000 Hz.

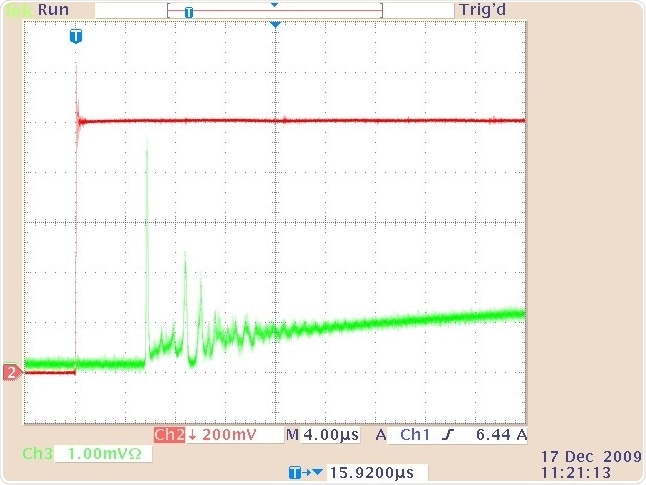

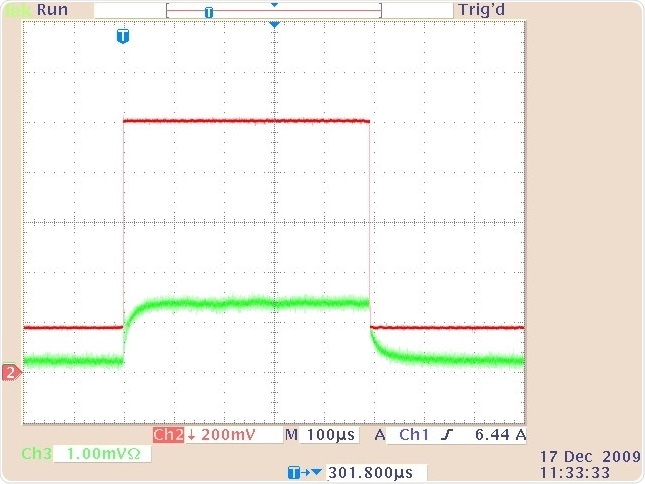

Figure 5. The quasi-cw laser output (lower trace) and drive current waveform (upper trace) showing the relaxation oscillations at the beginning of the pulse shown in Figure 4. Image Credit: Sheaumann Laser, Inc.

At the onset of lasing, a series of gain-switched pulses are emitted, which transition into the established damped relaxation oscillation (Figure 5) condition. This precedes oscillation free quasi-cw laser operation, which is terminated once the pump pulse has been extinguished.

It is possible to measure a build up time delay of 6 µs from the beginning of the pump pulse to the lasing threshold. This build up time delay reduces with higher peak pump powers, becoming negligible in line with the generation of millisecond duration pulses. The 100 µs transition to the stable quasi-cw is much more notable, when generating sub-millisecond pulses, however.

Relaxation oscillation damping time (τ0) of an ideal four level laser6 can be ascertained using the formula below.

In this formula, the upper laser level’s (τ) characteristic lifetime can be adjusted via the ratio of population inversion density at threshold to the total number of active ion sites in the pumped region of the gain medium (Nth Nt) and the number of times the optical pumping rate is observed as exceeding the lasing threshold (Wp Wp,th).

It is evident that pumping harder reduces relaxation oscillation damping time, and this core principle also applies to the 2.94-µm Er:YAG laser; despite its energy level dynamics being much more sophisticated than the energy level dynamic of the ideal four level laser.

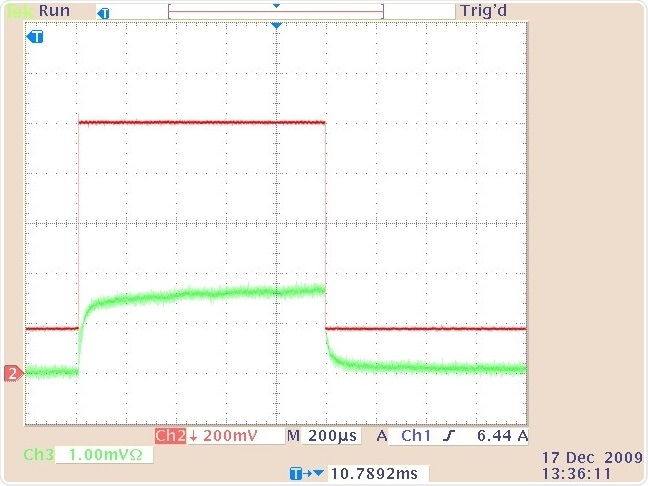

Figure 6. The quasi-cw laser output (lower trace) and drive current waveform (upper trace) for a 1.0 ms duration, 8.2 A current pulse superimposed on a 1.8 A continuous bias current at a 1000 Hz repetition rate. Image Credit: Sheaumann Laser, Inc.

Pumping the Er:YAG laser slightly under its lasing threshold prior to the main pumping pulse is able to reduce the relaxation damping time, almost completely eliminating any build up time delay (Figure 6).

The optimum pulsed drive current for the laser’s quasi-cw operation features a continuous bias current set between 80% and 90% of the continuous lasing threshold value (generally 2 A), plus a larger pulsed drive current.

Peak drive current may be as high as the 10 A maximum drive current of the diode pump laser, though this requires that the duty cycle corrected average 2.94-µm laser output power does not exceed the specified maximum operating power of the device.

After an optical pump pulse, the majority of quasi-cw lasers will switch off along with a monotonic decay in intensity. Sheaumann’s researchers noted this behavior when completely switching off diode pump lasers at the end of the pumping pulse.

Figure 7. The quasi-cw laser output (lower trace) and drive current waveform (upper trace) showing the relaxation oscillation decay at the end of the laser pulse shown in Figure 6. Image Credit: Sheaumann Laser, Inc.

When the diode pump laser operated continuously between pumping pulses (at slightly under the Er:YAG laser threshold) Sheaumann’s researchers observed a series of decaying relaxation oscillations (Figure 7) at the end of the Er:YAG laser pulse.

It has been theorized that these oscillations are a feature specific to the laser’s dynamic response, due to the continued and gradually decaying optical pumping of the upper laser level via phase delayed feedback provided by the upconversion pathway.

The Er:YAG laser’s pulsed peak power capability is ultimately limited by the thermal fracture mechanism that limits this during continuous operation. This is specified at 1 W for the current product, but device improvements over time have resulted in potential operation up to 1.5 W (Figure 1).

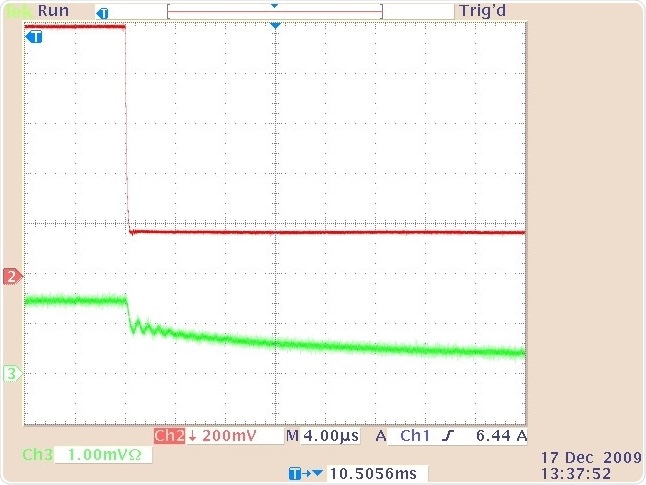

Corresponding recommended peak power for quasi-continuous operation limited to a duty cycle of 10% and 1 ms pulses at a repetition rate of 100 Hz - would be >10 W. Despite this, the pump diode laser included in the standard 2.94 µm MIR-Pac Er:YAG laser product is limited to a maximum drive current of 10 A in practice, which typically corresponds to peak powers up to 2.5 W.

Figure 8. The quasi-cw laser performance at a fixed pulse repetition rate of 100 Hz for 8.2 A drive current pulses superimposed on a 1.8 A continuous bias current. Image Credit: Sheaumann Laser, Inc.

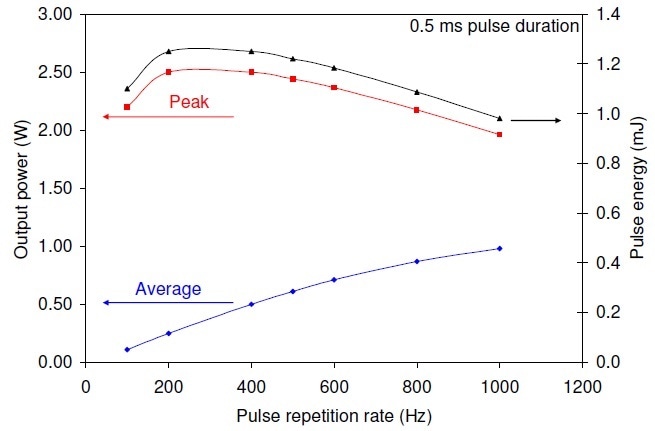

Figure 9. The quasi-cw laser performance at a pulse duration of 0.5 ms for 8.2 A drive current pulses superimposed on a 1.8 A continuous bias current. Image Credit: Sheaumann Laser, Inc.

Figures 8 and 9 contain data illustrating the generation of up to 2.5 W peak powers in quasi-cw operation. These examples are operating at the maximum drive current limit to generate millisecond regime pulses at pulse repetition rates.

In the examples presented here, it was possible to generate maximum pulse energies of 9 mJ for 5 ms pulses at 1.8 W of peak power. It was only possible to achieve the average power limit at duty cycles of approximately 50% and pulse peak powers as high as 2 W. Corresponding pulse energies were found to be 1 mJ at 1 kHz.

Operating at low duty cycles with longer intervals between laser pulses causes transient thermal lensing, which results in undesirable spatial mode modulation. Operating the Er:YAG laser close to its threshold (without lasing) in between laser pulses can address this issue, as this introduces a significant fraction of the thermal lens experienced under typical lasing conditions.

Figure 10. The quasi-cw laser output (lower trace) and drive current waveform (upper trace) for 0.5 ms duration. 10 A drive current pulse. Image Credit: Sheaumann Laser, Inc.

Figure 11. The quasi-cw laser output (lower trace) and drive current waveform (upper trace) for 0.5 ms duration. 8.2 A drive current pulse superimposed on a 1.8 A continuous bias current. Image Credit: Sheaumann Laser, Inc.

Figure 10 highlights this issue, whereby the rising edge of the pulse walks through a number of relaxation oscillation events suggesting multiple spatial mode evolution. The elimination of this problem is shown in Figure 11.

Figure 12. Direct Beam Output. Image Credit: Sheaumann Laser, Inc.

The data presented here was acquired from an Er:YAG laser housed in a hermetically sealed windowed package (Figure 12). Recently, Sheaumann evaluated fiber-coupled versions of this laser package with 0.22 NA ZBLAN (IRphotonics) fibers, ranging in core diameter from 150 µm to 450 µm.

Figure 13. Fiber Coupled Version. Image Credit: Sheaumann Laser, Inc.

Direct beam output

Fiber-coupled output powers of 1.1 W were obtained for a total of 1.3 W of power incident on the input face of 1.5 m long fibers of each core size. Once output fiber face Fresnel loss had been accommodated, it was estimated that power coupling efficiency was >90% (Figure 13).

Fiber coupled version

Sheaumann has also successfully designed and developed an efficient diode-laser-pumped 1.5 W, cw 2.94 µm Er:YAG laser, which features a TEM00 output beam housed in a hermetically sealed windowed package.

This laser includes a fiber-coupled output beam delivery option which delivers 1.1 W from 150 µm to 450 µm core diameters and 0.22 NA ZBLAN (IRphotonics) optical fibers. This innovative laser has been demonstrated as operating in the quasi-cw mode, able to generate pulse energies as high as 10 mJ in a 5 ms pulse at a 100 Hz repetition rate.

It has also been possible to generate 1 mJ pulses at repetition rates from a single-shot to 1 kHz. Millisecond duration laser pulses like these offer high beam quality and are an optimal solution for applications necessitating the use of controlled heat deposition in limited volumes of material. This typically involves materials with some water content due to the operating wavelength, however.

Work at Sheaumann is ongoing in order to increase the cw laser output power to several Watts using a longer traditional laser resonator rather than a microlaser chip.

Sheaumann’s researchers are also looking to scale both pulse energy and peak power in the quasi-cw regime of operation using higher peak power pump laser diodes and the current Er:YAG microlaser chip. The overall aim of this work the generation of >5 mJ in 1 ms.

References

- Chen, D., Fincher, C.L., Todd, S.R., Vernon, F.L. and Fields, R.A., “Diode-pumped 1-W continuous-wave Er:YAG 3-µm laser,” Opt. Lett., 24, 385 (1999).

- Dinerman, B.J. and Moulton, P.F., “3-µm cw laser operation in erbium-doped YSGG, GGG and YAG,” Opt. Lett., 19, 1143 (1994).

- Stoneman, R.C. and Estrowitz, L., “Efficient resonantly pumped 2.8-µm Er3+:GSGG laser,” Opt. Lett., 17, 816 (1992).

- Georgescu, S. and Toma, O., “Er:YAG three-micron laser: performances and limits,” IEEE. Sel. Top. Quant. Electron., 11, 682 (2005).

- Meister, J., Franzen, R., Apel, C. and Gutknecht, N., “Multi-reflection pumping concept for miniaturized diode- pumped solid-state lasers,” Appl. Opt., 43, 5864 (2004).

- Zayhowski, J.J., Welford, D. and Harrison, J., [The Handbook of Photonics; Miniature Solid-State Lasers], CRC Press, (2007).

Acknowledgments

Produced from materials originally authored by John Gary Sousa and Josh Foster from Sheaumann Laser, Inc., and David Welford from Endeavour Laser Technologies.

About Sheaumann Laser, Inc.

Sheaumann Laser specializes in the design and manufacture of semiconductor laser diodes and modules for sensing, imaging, telecom, navigation, and illumination applications for the industrial, defense, and medical industries. We also produce space-qualified lasers for data transmission from satellites.

All of our R&D and production activities are efficiently housed in one centralized facility near Boston, giving us complete control over all processes and the flexibility to create custom solutions for OEMs with unique requirements.

Our 18,000 square foot cleanroom houses all activities, from wafer growth to test and reliability, under one roof. Our quality management system is certified to ISO 9001:2015 and CMMC readiness Level 3 for NIST SP 800-171, FAR 52.204-21 and DFARS 252.204-7012 compliance. Our products also comply with RoHS 3 and REACH requirements.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.