Sponsored Content by Mo-SciReviewed by Alex SmithDec 8 2023

Bioactive glasses, also called bioglasses, are silica-based biomaterials with a three-dimensional silicon-oxide network, including calcium, sodium, and phosphorus oxides. They are compatible with the human body as they bond to soft tissue and bone and stimulate new bone growth.

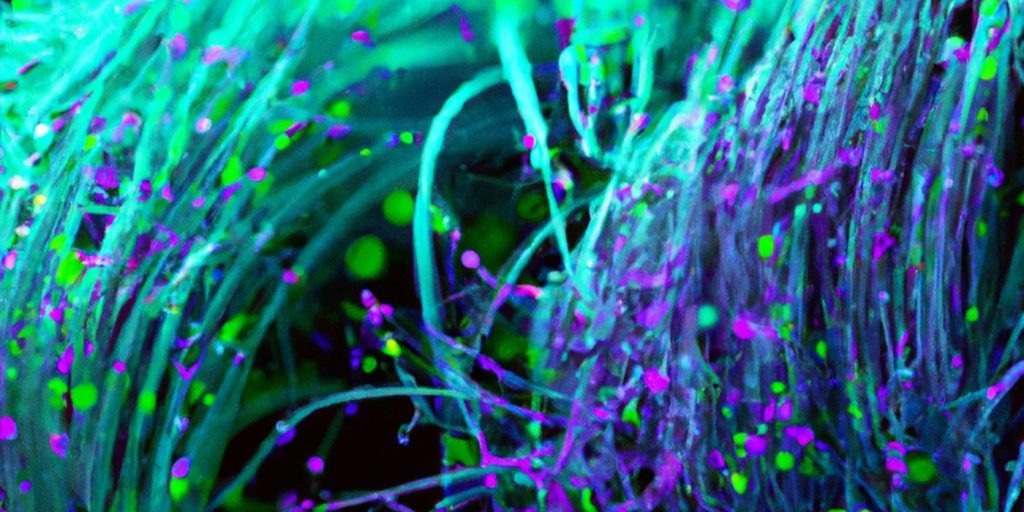

Image Credit: Mo-Sci

Such biomaterials can potentially restore damaged or diseased bone to its previous state.1 By modifying their structure and composition, it is also possible to modify their physical properties to meet a specific requirement and control how long they last in the body before degradation occurs.2

The history and development of bioactive glass

In 1969, the first bioactive glass material was developed by Larry Hench, a professor of ceramic engineering at the University of Florida. Hench collaborated with doctors during the Vietnam War to create a material that could replace bone and other tissue types in severely wounded soldiers.3

Hench’s discovery led to a new field of research in ‘bioactive’ materials. At this time, biomaterials research was primarily about making materials as unreactive as possible to reduce the body’s inflammatory response and te likelihood that the body would reject the implant device or material.

Researchers at this time were oblivious to the potential that an artificial material has for aiding the regeneration or healing of tissue.

However, Hench’s team discovered that its material, later trademarked as Bioglass®, could bond with bone. This was the first time that researchers had seen a surface bond formed between implanted material and tissue.4

This first bioactive glass (45S5) comprised four components: calcium dioxide, silicon dioxide, sodium oxide, and phosphorus pentoxide. The name 45S5 denotes the 45% weight of silicon dioxide and the 5:1 molar ratio of calcium to phosphorus.

This composition was vital to the highly reactive material in bioactive and aqueous fluids.

Hench and his team tested bone implants of the material in rats and discovered their removal was difficult after six weeks.

The reported strength of the interfacial bond between the bone and Bioglass® was greater than or equal to the strength of the host bone.5 Over time, it became evident that Bioglass® could form bonds with soft connective tissues.6

The team studied a variety of compositions, including experimenting with silica levels, adding fluoride and boron, and comparing crystallized to amorphous states.

Hench discovered that different compositions impacted the rate of bone bonding as well as the stability and strength of the bond. For 45S5, the bonding was quick at silica levels within the range of 42–53%, taking 2–4 weeks at 54–60% silica levels, with bonding not occurring at all over 60% silica.

The team investigated the sequence of reactions following the implantation of bioactive glass in bone or soft tissue. This complex and multistage process generates a layer of biologically active hydroxycarbonate apatite (HCA).

Like the mineral phase in bone, it seemingly helps bone cells to adhere to and grow on the implant surface and is ultimately replaced by bone.1

In the 1990s, it was revealed that these glasses release biologically active, soluble calcium and silica ions, which stimulate the cells that secrete the material for stem cells and bone formation (osteoblasts).1

This research conducted by Hench and others proved that ionic release and the HCA layer are how bioactive glasses stimulate cell growth and speed up the healing process via the repair of tissues.

It is now understood that some bioactive glasses can stimulate the development of new blood vessels (angiogenesis) and have antimicrobial activity due to this release of ions.

Overcoming challenges of bioglass

Although bioglass has many benefits, the original bioglass has disadvantages, including being mechanically weak and brittle.7 Scientists designed bioactive glass polymer hybrids to strengthen them and make them more resistant to fracture.8

In these materials, if the production process is carefully controlled, networks of both organic and inorganic components combine and bond at the nanoscale. The scientists also discovered that hybrids' degradation rates and mechanical properties are more easily controlled than original bioactive glasses.

It was challenging to make the original biomaterials into porous structures appropriate for scaffolds in tissue engineering due to how they crystallize during sintering (a heat treatment process utilized to create porous materials). Scientists addressed this by using a different approach to make the glass.8

Conventionally, making glass (melt-quenching) involves temperatures exceeding 1300 °C. However, the sol-gel chemistry-based method enables the assembly of silica nanoparticles at room temperature.

Other advances in processing (foaming, solid freeform fabrication, and nanofiber spinning) result in porous bioactive glass scaffolds being produced from melt and sol-gel glasses.

Nanotechnology advancements have enabled scientists to produce bioactive glass nanoparticles that can transport genetic or therapeutic material or be tracked within cells.8 Both melt and sol-gel glasses can be manufactured as nanoparticles.

Bioactive glass applications

The first application of bioactive glass was as a middle ear prosthesis in 1985. Since then, bioactive glass has been widely utilized in biomedical applications, such as dental reconstruction, bone grafting, and wound healing.

This versatility is due to the ability to stimulate new bone and soft tissue growth and new blood vessels that deliver nutrients to the new tissue. These glasses can also be tailored to suit each application.

Particulate forms are well-suited for spine implants, while fine particulates are best suited for dental applications and fibrous glasses as wound dressings. The focus has recently been the engineering of tissue and cell-seeded porous scaffolds that allow full integration into the body.

Silicate-based bioglasses are suitable for several dental and orthopedic applications. Variations on the original material include bioglass 13-93, which comprises more silicate (50-56%) than 45S5 and includes network modifiers, such as magnesium and potassium oxides.

It performs as well as 45S5 regarding the encouragement of bone to grow but it is stronger than 45S5 and is quicker to degrade.9 This material is employed for bone grafts and in repairing periodontal and facial defects, blood loss control, and wound care.

Some bioglasses have antibacterial properties, such as S53P4, which contains 53% silica and lower calcium, sodium, and phosphorus weights than 45S5. It was developed at Åbo Akademi University and the University of Turku in Finland in the early 1990s.10

Sodium ions are released when the implant encounters bodily fluids, which raises pH. Other released ions join to increase salt concentration levels, increasing osmotic pressure. These conditions hinder the growth of bacteria.

The antimicrobial effects of bioactive glass can be enhanced using ions, such as copper, boron, yttrium, silver, iodine, or organic nanoparticles.

Borate-based glasses have demonstrated antimicrobial properties against various bacteria, such as E-coli and MRSA. As evidenced by research, bacteria cannot stick to these glasses, making them particularly valuable for preventing infections in burns and wounds.

One example of this is Mirragen®, developed by a team at Mo-Sci (Rolla, Missouri, USA) involving Mo-Sci cofounder Delbert Day and Steven Jung, a graduate student at the Missouri University of Science and Technology and now Chief Technology Officer at Mo-Sci.11

Jung worked with the former CEO of Mo-Sci, the late Ted Day, to refine the material for FDA approval in 2017 for wounds treatment. Rediheal® is a similar product employed by veterinarians for healing major wounds in animals.

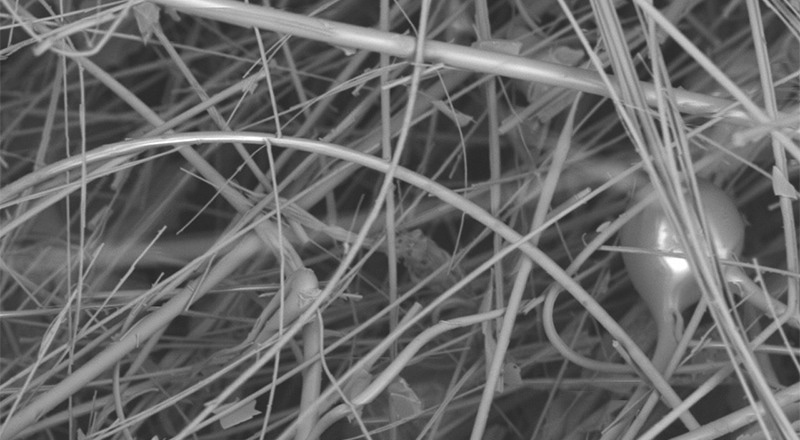

With a high calcium content, fibrous glass was the world's first bioactive glass-based wound care product. It has now been proven to assist chronic diabetic ulcer healing. Its fiber structure enables Mirragen® to absorb fluid from the wound site to facilitate healing.

SEM image of Mirragen® bioactive glass fiber at 800x magnification. Image Credit: Mo-Sci

In addition to preventing infection, borate-based bioglasses help tissue regeneration by encouraging cells to secrete the growth factors involved in blood vessel regrowth, which are critical for tissue development as they deliver all required nutrients.

This makes the bioactive glass highly beneficial to creating tissue engineering scaffolds, as recombinant growth factors were previously required.

These materials also accelerate the healing process because borate-based glasses react five to ten times faster than 45S5 in the conversion process, i.e., converting a bone graft into hydroxyapatite, which can subsequently be remodeled into bone.

As a result, borate-based glasses have also been employed as coatings for dental and orthopedic implants, bone grafts, and materials for tooth fillings.12,13,14

Another class of bioglasses is based on phosphates and frequently includes other additives, such as zinc, copper, or silver oxides. These are not as rigid as silicate glasses and may be prepared in various forms, such as discs, spheres, and microspheres.15

These glass fibers can form microtubes, which may be incorporated within a range of polymers to help the diffusion of nutrients and the regrowth of blood vessels when utilized as scaffolds for regenerating tissue.

Microspheres have been utilized in radiotherapy as they offer a stable surface for the growth of cells and the prevention of tissue damage.

Mo-Sci’s role in bioglasses

Most of the bioactive glass used today in medical devices is produced by Mo-Sci, and can be traced back to the first days of the first bioglasses when Larry Hench selected the start-out company to produce the glass he required to manufacture products through his company U.S. Bioglass.16

Founded by Delbert Day in 1985, Mo-Sci was a spin-off from Day’s work on radioactive glass spheres at the Missouri University of Science and Technology.

Mo-Sci’s first product was a glass microsphere employed in TheraSphere®, a technology for delivering minute amounts of radioactive materials to treat inoperable liver cancer.

Since then, the company has developed various bioactive glasses, including microspheres, glass powders (frit), and porous structures.

These materials are offered in various sizes and compositions depending on the form of the glass and the intended application. Mo-Sci also offers custom-made bioactive glass for specific degradation rate and strength needs.

The company’s products may be employed in various healthcare and medical applications, such as implant coatings, powders for mixing with composite materials, and tissue engineering scaffolds.

The latest bioactive glasses from Mo-Sci are borate-based, which use boron rather than silica for the glass former (see Mirragen® above). The company has an exclusive license for soft and hard tissue applications for these glasses.

The Mo-Sci spin-off company, Engineered Tissue Solutions (ETS), now distributes Mirragen®.

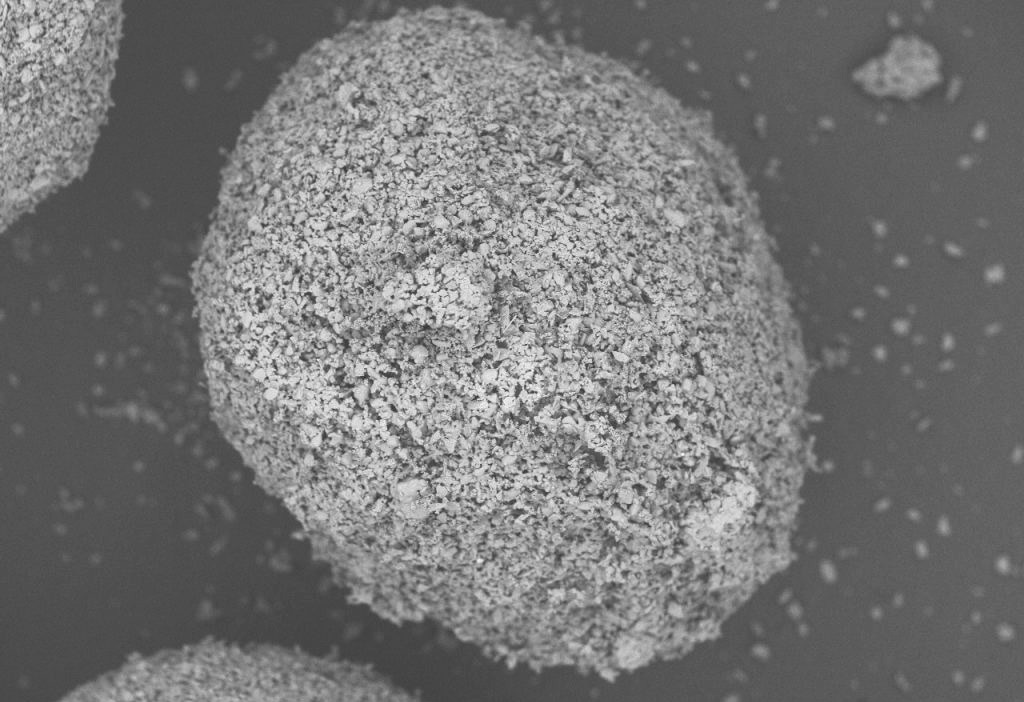

The company works closely with medical professionals and the healthcare industry. For instance, the highly porous material Porogran was designed in collaboration with surgeons for utilization in implantable grafts and scaffolds.

Porogran can be used as a granular material or processed into putty or collagen strips. Because of its high surface area, reactions occur more quickly. Porogran can be produced in several bioactive glass compositions, including 45S5 and S53P4.

SEM image of Porogran bioactive glass. Image Credit: Mo-Sci

Mo-Sci has been involved with bioglass from the very beginning, which means the company can provide a unique combination of extensive expertise and experience in glass science, healthcare applications, and product development.

References and further reading

- Greenspan D. Bioglass at 50 – A look at Larry Hench’s legacy and bioactive materials. Biomed. Glasses 2019; 5:178–184

- Rahaman M.N., et al. Bioactive glass in tissue engineering. Acta Biomaterialia 2011;7:2355 2373

- Hench L.L. The story of Bioglass, J. Mater. Sci: Mater. Med., 2016, 17, 967-978

- Hench L.L. et al. Bonding mechanisms at the interface of ceramic prosthetic materials. Journal of Biomedical Materials Research Volume 5, Issue 6 p. 117-141

- Jones J.R. Introduction – the discovery of Bioglass. Chapter 12.1 Bioceramics and their Clinical Applications, 2008 edited by Kokubo T. Woodhead Publishing

- Wilson J., et al. Toxicology and biocompatibility of bioglasses. Journal of Biomedical Materials Research Volume 15, Issue 6 p. 805-817

- Kaur G., et al. Mechanical properties of bioactive glasses, ceramics, glass-ceramics and composites: State-of-the-art review and future challenges. Materials Science and Engineering: C Volume 104, November 2019, 109895

- Jones J. Reprint of: Review of bioactive glass: From Hench to hybrids. Acta Biomaterialia Volume 23, Supplement, 1 September 2015, Pages S53-S82

- Hoppe A., et al. In vitro reactivity of Sr-containing bioactive glass (type 1393) nanoparticles. J. Non-Cryst. Solids, 2014, 387, 41-46

- S53P4 bioactive glass in healthcare – International Year of Glass. 2022. S53P4 bioactive glass in healthcare – International Year of Glass – Bonalive

- Brown R.F. et al, Growth and differentiation of osteoblastic cells on 13-93 bioactive glass fibers and scaffolds. Acta Biomater. 2008 Mar;4(2):387-96

- Lopez-Esteban S, et al. Bioactive glass coatings for orthopedic metallic implants. Journal of the European Ceramic Society 2003;23:2921–2930

- Pugely AJ, et al. Influence of 45S5 Bioactive Glass in A Standard Calcium Phosphate Collagen Bone Graft Substitute on the Posterolateral Fusion of Rabbit Spine. Iowa Orthop J. 2017; 37: 193–198.

- Khvostenko D., et al. Bioactive glass fillers reduce bacterial penetration into marginal gaps for composite restorations. Dental Materials Volume 32, Issue 1, January 2016, Pages 73-81

- Islam M.T., et al. Bioactive calcium phosphate–based glasses and ceramics and their biomedical applications: A review. Journal of Tissue Engineering Volume 8, January-December 2017. https://doi.org/10.1177/2041731417719170

- Bioactive glass. Mo-Sci Bioactive Glass – Mo-Sci.

About Mo-Sci

Mo-Sci, a world leader in precision glass technology, explores and develops new and exciting ways for their products and services to integrate within a wide variety of useful applications.

Mo-Sci has become a world leader in the research, development, and manufacturing of glasses for specialty applications.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.