Sponsored Content by Merit SensorReviewed by Louis CastelMar 14 2025

During the COVID-19 pandemic, many medical studies highlighted the risk of barotrauma from mechanical ventilation, emphasizing the importance of precise pressure sensor devices.1,2,3

Pressure sensors, however, have a wide range of uses beyond medicine, including pneumatic systems, electronics, and dry, non-corrosive gas pressure devices.

Merit Sensor's CMS Series pressure sensors offer high-performance solutions for all of these applications. This article examines these sensors in the context of analyzers and ventilators, demonstrating why they are the preferred option of medical experts, engineers, scientists, and industry leaders worldwide.

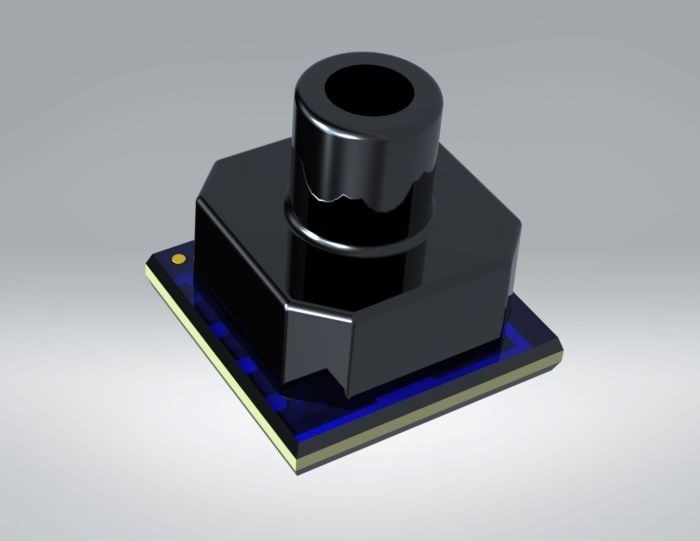

Image Credit: Merit Sensor

Analyzers and ventilators: In a nutshell

Analyzers are a large group of instruments that measure and profile many different substances, including gases, liquids, and blood samples. They play an important role in diagnostics, environmental monitoring, and quality control.

Blood gas analyzers, gas chromatographs, ECMO devices, and other equipment, such as air quality monitors, are equipped with analyzers to track contaminants and ensure appropriate indoor air quality. Pressure sensors are used to monitor and manage airflow and pressure levels to ensure that these systems work within optimal parameters.4

Mechanical ventilators, on the other hand, are specialized pieces of equipment that help patients breathe. These machines provide positive pressure 'breaths' to the lungs, guaranteeing proper oxygen circulation and CO2 outflow.

Ventilators accurately control airflow depending on patient-specific parameters such as pressure, volume, and breathing rate to fully support or augment spontaneous breathing. Precise pressure sensors are also essential for maintaining proper air pressure and avoiding issues like barotrauma.5

Enter the CMS Series by Merit Sensor

Merit Sensor's CMS Series is a high-performance pressure sensor series focused on precision and dependability. This sensor uses an ASIC for calibration and thermal correction, ensuring long-term, accurate pressure responses.

It has a piezoresistive Wheatstone bridge with glass connected to a chemically etched silicon diaphragm, which allows the sensor to remain stable under various environmental conditions.

Its compact size, broad operating voltage range, and low energy usage make it useful in a variety of applications. The CMS Series is appropriate for a wide range of pressure-sensing applications, including absolute and gage pressure options, as well as I2C and SPI digital outputs.

Merit Sensor, headquartered near Salt Lake City, Utah, designs, engineers, and produces its products in-house, ensuring quality control from beginning to end. The company's proprietary Sentium® technology offers best-in-class temperature stability, allowing sensors such as the CMS Series to work reliably even in extreme situations.

The company’s entire approach to development and production positions it as a market leader in high-precision pressure sensing products.6,7

CMS Series: Specifications breakdown

The CMS Series' unique profile distinguishes it from other pressure sensors on the market, making it the preferred choice for both analyzers and ventilators.

1. High precision

Whether employing analyzers or ventilators, high precision is essential to produce data that accurately reflects sample conditions. The CMS Series provides accurate pressure measurements (±0.25 % full-scale output) for peace of mind in situations where small errors impact performance and patient outcomes.4

2. Durability and stability

These sensors, which are built with a durable silicon piezoresistive element, enable long-term repeatability and can work in harsh outdoor climates and hospital settings. Their stable functioning over time lowers the need for regular maintenance or calibration.6

3. Wide pressure range

The CMS Series offers a wide range of pressures—from -2 to 150 psi—to meet the demands of both high- and low-pressure applications. Its adaptability makes it appropriate for a wide range of devices and industries.4

4. Compact design

The CMS Series, being only 6.8 mm × 6.8 mm, is compact enough to be easily integrated into compact devices while maintaining performance. This is a huge advantage for manufacturers who create portable or space-constrained equipment, such as handheld analyzers.4

5. Temperature compensation

CMS Series sensors are also outfitted with temperature compensation over a range of -40 °C to 85 °C, making them reliable even in fluctuating environmental conditions.7

6. Low power consumption

Efficient power consumption is critical in equipment that requires continuous operation, such as ventilators, as well as battery-powered analyzers used in the field. The CMS Series' low power mode assures minimal energy consumption while maintaining performance.6

7. Domestic manufacturing

All CMS Series items are proudly made in the United States, providing the highest level of quality and compliance with local rules.4

8. RoHS compliant

All products are RoHS compliant, meaning they meet the European Union's special environmental safety regulations.6

Merit Sensor's CMS Series: A precision and performance benchmark

The CMS Series uses cutting-edge pressure-sensing technology, combining innovation and precision, to give unparalleled performance.

With its innovative design, temperature correction, and energy efficiency, it is an essential component in life-saving medical devices such as ventilators and environmental analyzers.

The CMS Series, manufactured in the United States with a commitment to exceptional quality, is designed to adapt to changing needs. Its adaptability ensures that professionals worldwide, from engineers to healthcare providers, can rely on it to operate under the most demanding conditions.

References and further reading

- Serck, N., et al. (2023). Barotrauma in COVID-19 acute respiratory distress syndrome: retrospective analysis of the COVADIS prospective multicenter observational database. BMC anesthesiology, 23(1). https://doi.org/10.1186/s12871-023-02093-1.

- Belletti, A., et al. (2021). Predictors of Pneumothorax/Pneumomediastinum in Mechanically Ventilated COVID-19 Patients. Journal of Cardiothoracic and Vascular Anesthesia. (online) https://doi.org/10.1053/j.jvca.2021.02.008.

- Rajdev, K., et al. (2021). Pulmonary Barotrauma in COVID-19 Patients With ARDS on Invasive and Non-Invasive Positive Pressure Ventilation. Journal of Intensive Care Medicine, 36(9), pp.1013–1017. https://doi.org/10.1177/08850666211019719.

- Merit Sensor DS-045T – CMS1610 Technical Datasheet.002. Available at: https://meritsensor.com/assets/documents/pdf/CMS-Series.pdf.

- Hickey, S.M. and Giwa, A.O. (2024). Mechanical Ventilation. (online) PubMed. Available at: https://www.ncbi.nlm.nih.gov/books/NBK539742/.

- Merit Sensor. (2023). CMS Series - Merit Sensor. (online) Available at: https://meritsensor.com/products/cms-series/ (Accessed 29 Jan. 2025).

About Merit Sensor

One size does not fit all. Whether it is design assistance, custom products or smaller volumes, clients need flexible solutions instead of rigid excuses.

In addition to our standard products, we offer an array of design and manufacturing services.

As the leader in piezoresistive pressure sensing, we are ready and able to address key issues such as media compatibility, sensitivity or packaging feasibility. Instead of searching for and interfacing with a variety of sources, we’ll get you the answers you need to get your products up and running quickly.

Design

We offer the following design services:

- Customization (sensitivity, resistance, bridge configurations, pressure ranges, pressure types, packages, etc.)

- Analysis (application, media, packaging etc.)

- Verification (prototyping, testing, etc.)

If we can’t do it for you, we will likely know who can and we will refer you to them.

Manufacturing

Because we own and operate our own wafer fabrication facility, we can offer the following manufacturing services:

- Customized manufacturing

- Selected contract manufacturing

- Small volume runs

Considering the years we have been in business, chances are we have or can create a solution for you.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.