Simplify and accelerate the creation of your lyophilized amplification assay to expedite the development of your point-of-care application.

Overview

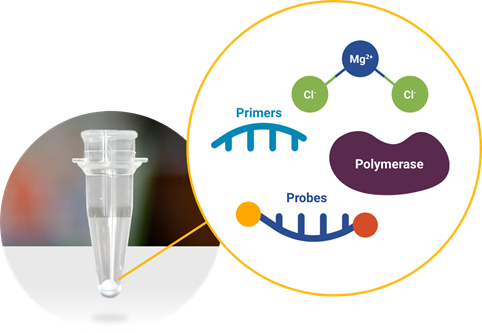

Everything users need in a single bead

Promega has dedicated time to perfecting reagent formulations to better serve its clients, shorten the development process, and reduce hazards associated with the lyophilization process. The lyophilized beads provide a versatile format that streamlines sample preparation while also meeting the stability and storage requirements of commercial applications.

Image Credit: Promega Corporation

Accelerate the time to results

One bead consists of the complete reaction—users just need to add a sample. This streamlines the sample preparation procedure, saves time, and increases consistent, dependable performance by lowering the possibility of human mistakes.

The adaptable fit-for-purpose lyophilization capabilities can be tailored to meet individual requirements, regardless of whether the customer wants a basic PCR test or a thorough reaction including primers and probes.

Flexible, scalable format

The lyophilized beads provide a format that minimizes waste while supporting and improving productivity. Among the advantages are:

Bulk. Image Credit: Promega Corporation

Bulk with Primers and Probes. Image Credit: Promega Corporation

8-Well Strip Tube. Image Credit: Promega Corporation

96-Well Plate. Image Credit: Promega Corporation

Adaptable format

As manufacturing demands evolve, beads can be readily scaled to suit any reaction volume and application.

Flexible dispensing options

Beads can be dispensed to meet any format requested by the user, such as bottles, 96-well plates, and 8-well strip tubes.

Easy integration for sample-to-answer assays

Bead format facilitates integration into the design and manufacture of sample-to-answer diagnostics.

Ambient storage

Without cold-chain transportation or storage, reactions remain stable.

Partnerships process

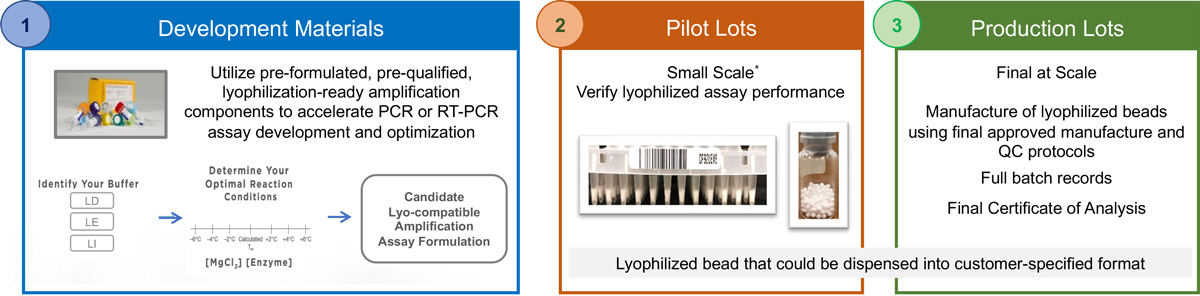

Lyophilization partnership process

When it comes to the creation, validation, and manufacturing of a lyophilized PCR amplification test, Promega can assist its clients effectively. These are the steps involved in creating a lyophilized PCR amplification test suitable for its intended use.

Summary of Fit-for-Purpose Lyophilized PCR Amplification Assays. Image Credit: Promega Corporation

*Minimum order quantity required

Capabilities

Lyophilization development and manufacturing capabilities all under one roof

Primary manufacturer

Being the leading producer of PCR enzymes and reagents, Promega has complete control over the entire product manufacturing process, from raw materials to the final product. Promega can avoid lag time and efficiently remove supply chain uncertainty to assure consistent supply with different global inventory locations and integrated logistical assistance.

Image Credit: Promega Corporation

Fit-for-purpose service

Working with a lyophilization service provider who is also a reagent supply will help users avoid the extra time, complications, and handoffs that might delay the development process. With the full custom service solutions, Promega can provide a custom solution that best fits the workflow, regardless of whether users need only reagents or a complete kit with primers and probes.

Image Credit: Promega Corporation

Experienced, trusted partner

Promega has been a top supplier in the PCR and amplification industries for almost 40 years. Utilize the knowledge and skills, and work closely with the scientists who are developing, producing, and testing the products.

Image Credit: Promega Corporation

Quality manufacturing

Take advantage of all the advantages of a customer-focused quality system without having to develop the controls or invest in the necessary equipment. To guarantee consistent, dependable manufacturing, Promega's products are produced under a strict quality system that complies with ISO9001 and ISO13485 standards.

Image Credit: Promega Corporation

Environmentally sustainable

Shelf-stable reactions with no special storage conditions needed. Image Credit: Promega Corporation

Reduced shipment packaging cuts carbon footprint of transport. Image Credit: Promega Corporation

No need for hazardous chemicals. Image Credit: Promega Corporation

No dry ice and transporting via cold chain required. Image Credit: Promega Corporation

Let’s discuss your product requirements!