The BTA Frontier represents a new standard in breakthrough adsorption analysis, providing unparalleled accuracy in evaluating packed beds under realistic operating conditions. Equipped with sophisticated sensors for detecting CO₂, H₂O, and organic vapors, the instrument precisely quantifies competitive adsorption phenomena involving multiple gaseous and vapor-phase species.

This capability facilitates in-depth characterization of sample properties and performance.

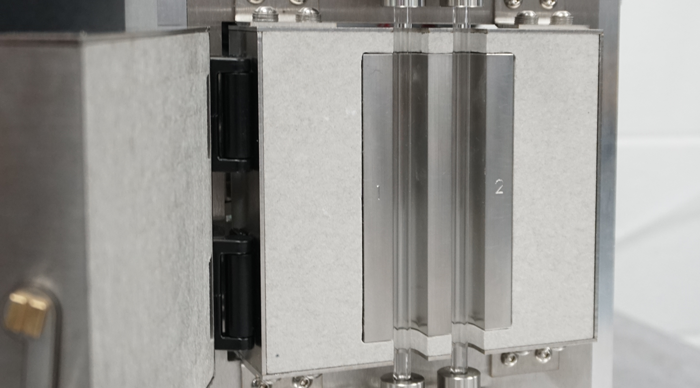

Engineered for optimal productivity, the BTA Frontier incorporates a dual-sample column configuration, enhancing throughput and enabling multi-component adsorption studies. These studies are supported by precise control over gas-phase composition and accurate adsorbate detection. Furthermore, the system's rigorous temperature and flow control mechanisms ensure exceptional data reliability and confidence in experimental outcomes.

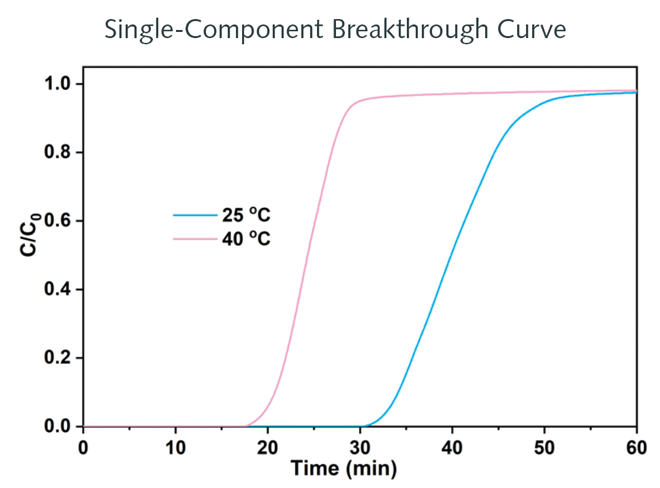

Single and multicomponent breakthrough

Measure the kinetics and uptake of gases and vapors (e.g., CO₂, VOCs) using different components (e.g., humidity, N₂).

Elevating throughput

Dual sample columns make sequential experiments and automation possible, improving throughput.

Customizable sensor array

A high-sensitivity TCD, specialized sensors for CO₂, water, and organics, and other sensors remove the need for a mass spectrometer.

Ultimate accuracy and flexibility

Automated apparatus for precise mixture preparation and measurement requiring few samples.

Benefits

Image Credit: Surface Measurement Systems Ltd

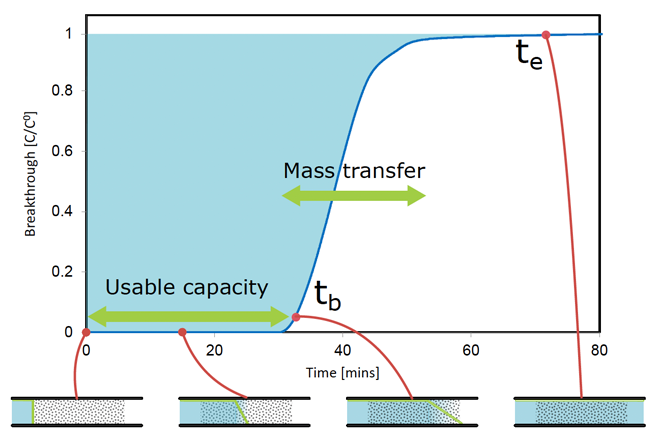

Comprehensive adsorption analysis

To fully comprehend adsorption properties and material performance, perform single and multi-component sorption experiments, including sample regeneration and cycling.

Real-world multi-component testing

To accurately analyze competitive adsorption, replicate real-world conditions by examining the absorption of one gas or vapor in the presence of others (such as CO₂, VOCs, and water, N₂).

Enhanced throughput and efficiency

The dual-column design facilitates parallel activation by eliminating downtime and permitting successive experiments. This increases throughput and yields maximum lab output.

Broad measurement range

The BTA Frontier allows for precise analysis across various concentrations for various research and testing applications by measuring VOCs from ppb to high% and CO₂ from ppm to high%.

Adaptability to sample types

It is highly versatile for various materials and applications because it can handle sample masses between 30 and 3000 mg and various morphologies (such as pellets and monoliths).

Precision and control

Gives each experiment more reliability by using an optimized flow path with pressure transducers, specialized mass flow meters, and automated dead volume determination for accurate, reliable results.

Capabilities

Image Credit: Surface Measurement Systems Ltd

- The experimental procedures encompass sorption with single and multiple components, as well as sample regeneration and cyclical testing

- To replicate conditions found in practical applications, samples are localized and heated within a temperature range of 5 to 60 °C.

- The feed side is equipped with a maximum of five gas inlets, allowing for the introduction of solvents, humidity, and various gases.

- Sample masses vary from 30 mg to 3000 mg, and the samples are prepared in different forms, including pellets and monolithic structures.

- Sample columns are offered in stainless steel and silanized glass, with 2 mm, 3 mm, 4 mm, and 1 cm internal diameter options.

Applications

- Material Characterization

- Carbon Capture, Utilization, and Storage

- VOC Capture and Remediation

- Adsorbent Process Scale-up

Specifications

Construction materials

- Custom-built manifold: 316 stainless steel

- Tubing: 1/16- or 1/8-inch 316 stainless steel

- Seals: Viton. or equivalent, Kalrez. optional

Inlet flow control

- Up to six gas inlets

- Turn-down Ratio up to 1000:1

- Calibrated gases include: N2, CO2, He, O2, Ar, and more

- Control Range per MFC: FS up to 200 sccm

Temperature control

Incubator control

- Control Range: 5 °C to 60 °C

- Control Accuracy: ±0.1 °C

- Controls the complete gas mixing, vapor generation, and measurement system

Column oven

- Control Range: Up to 500 °C

- Control Accuracy: ±.2 °C

Sample and configuration

- Small sample amounts (~30 to 3,000 mg)

- Two-column quick-connect system

Column sizes

- Length: 165 mm

- Glass: 2, 3, 4, 10 mm ID

- Stainless Steel: 3-4 mm ID

Pressure transducer

- Pressure transducers at column inlet and outlets

- Accuracy better than 1.0 % F.S.

- Full scale 0-2.5 bar

- Temperature compensated

Vapor generation

Liquid reservoirs

- Heated to prevent evaporative cooling

- Two 50 mL easy-change reservoirs are possible

Vapor generation range

- 0 – 90% for 5-60 °C

- Accuracy: ± 0.5 p/p0

|

Gas and vapor sensors

Humidity measurement

- Measurement Range 0-100 %RH

- Accuracy (5-40 °C) ± 0.8 %RH

- Accuracy (40-85 °C) ± 1.5 %RH

CO2 measurement

- % level 0-20% vol, atmospheric pressure, accuracy down to 0.1 %vol CO2

- Ppm level 0-30,000 ppm, accuracy down to ±40 ppm CO2

Thermal conductivity detector (TCD)

- High corrosion resistance

- High-temperature capability up to 180 °C

- Quick response – T90 ≤ 3 sec

Organics measurement (PID)

- 0 – 98% for 5-60 °C

- Low-range sensor: 1 ppb-40 ppm

- Mid-range sensor: 0-4000 ppm

- High-range sensor: 0-10,000 ppm

System information

- Dimensions: 520 mm (W) × 980 mm (H) × 610 mm (D)

- Electrical: 200 – 240 v, 50/60 Hz, 1500 VA

- Weight: 80 kg (180 lb)

System software

Instrument control software

- Effective custom methods and sequences

- Complete parameter control

- Live data viewing and plotting

- Component identification

- Variations in temperature within a single experiment

- Multiple concentrations or temperature cycles.

BTA analysis software

- Capacity correction for dead volume in many components

- Ease of plotting of normalized and molar concentrations and other custom plots

- User-defined control over calculation parameters

- Software that calculates many components' dead volume corrected capacities

|

Schematics

Image Credit: Surface Measurement Systems Ltd

Find out more about the BTA frontier

Image Credit: Surface Measurement Systems Ltd

The BTA Frontier is an intriguing new tool that offers researchers worldwide new possibilities.