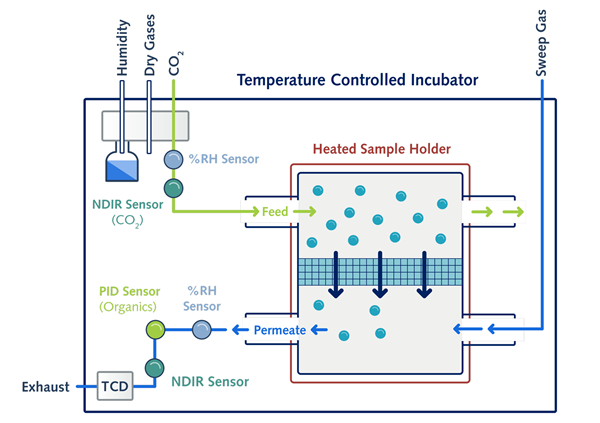

The Membrane Permeation Analyzer (MPA Horizon) is a self-contained cross-flow gas permeation device designed to investigate the competitive permeation of gases and vapors through barrier films and membranes. It enables a thorough evaluation of membrane performance by measuring key parameters such as the oxygen transmission rate (OTR) and water vapor transmission rate (WVTR), while offering multi-component analysis capabilities.

The penetration of gases or vapors through most membranes is significantly affected by environmental factors, particularly temperature and humidity. The MPA Horizon enables the testing of gas and vapor permeation, as well as permeation kinetics, under real-world conditions.

Looking for greater efficiency?

Image Credit: Surface Measurement Systems Ltd

The MPA Horizon tackles the critical issues researchers confront while assessing polymer barrier performance. It provides critical insights into material performance by precisely monitoring the transmission rates of water vapor, oxygen, and CO2 across polymer films.

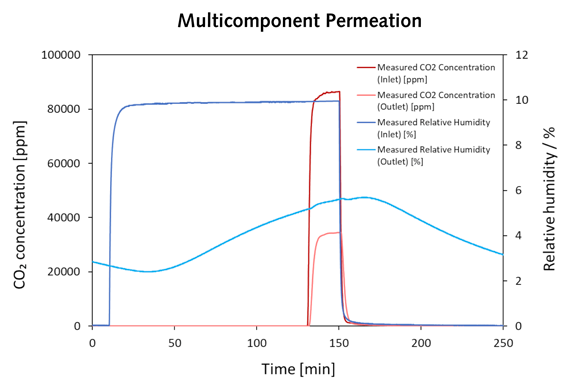

The MPA Horizon enables researchers to investigate the effect of changing environmental conditions—such as temperature, humidity, and the presence of organic compounds—on component permeation across membranes. This capacity is critical for understanding real-world permeation behavior and modifying materials to improve barrier characteristics.

Multi-component permeation analysis

Simultaneously analyze complicated mixes of gases, vapors, and humidity to gain a thorough understanding of material performance under a variety of instances.

High sensitivity sensors

The MPA Horizon is equipped with modern sensors that allow for precise measurement of water vapor, oxygen, and CO2 transmission rates. These high-sensitivity sensors provide accurate and trustworthy data, which is critical for determining the efficacy of polymers as barrier materials.

Measurement of permeation kinetics

Monitor and analyze permeation kinetics over time to better understand dynamic interactions and optimize materials for barrier characteristics.

Mimics real-world condition

Simulates variable temperatures, humidity levels, and organic compounds to correctly anticipate material performance in real-world applications.

Precise Water Vapor Transmission Rate (WVTR) measurement

Water vapor transfer rates are accurately measured from 0.05 to 500 g/m²/day (80 cm²).

Tunable Mass Flow Controllers (MFCs)

Gas flow rates are precisely controlled and adjusted to ensure reliable, reproducible results that may be applied to a wide range of research.

Benefits

Image Credit: Surface Measurement Systems Ltd

Real-world conditions

Analyze various temperatures, humidity levels, and organic compounds to predict material performance.

Multicomponent analysis

Investigate complex combinations of gases, vapors, and humidity to gain a thorough understanding.

Variable sample thickness

Sample thicknesses range from micrometers to millimeters, making it suitable for a wide range of material studies.

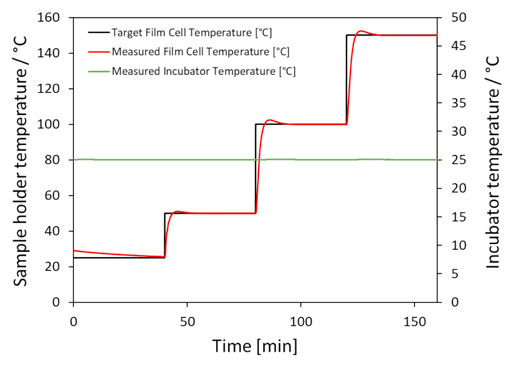

High-temperature capability

Heat samples to 150 °C to investigate temperature-dependent permeation behaviors.

Cross-flow configuration

Use nitrogen or helium carrier gases to provide efficient gas flow and accurate control.

User-friendly interface

Use easy controls and software to make setup and operation easier.

Rapid results

Obtain quick and reliable findings while saving crucial research and development time.

High reproducibility

Ensure consistent outcomes throughout several tests to obtain accurate data.

Capabilities

Image Credit: Surface Measurement Systems Ltd

- The production of single component flows of O2, CO2, or water vapor (>90% RH) in a carrier gas

- Permeation of several components and detection of vapors, gases, and humidity

- To replicate real-world conditions, the sample is locally heated between 10 and 15 ºC

- The feed side has five gas mixing inlets for gases, humidity, and solvents

- Detection alternates between feed and permeate streams

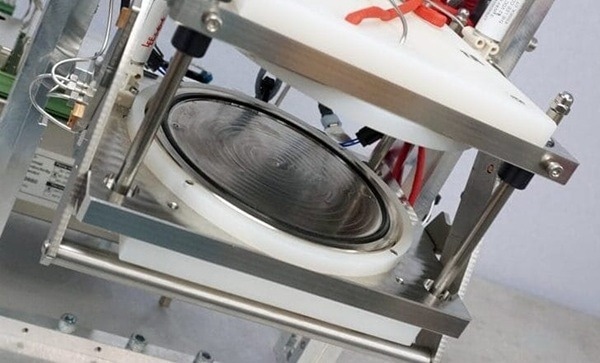

- Sample sizes range from small to large, with a maximum diameter of 11 cm

Applications

- Pharmaceuticals

- Cosmetics (contact lenses and wound dressings)

- Carbon capture with membranes

- Packaging film testing

- Membrane testing labs

- Electronics encapsulation

Image Credit: Surface Measurement Systems Ltd

Specifications

Construction materials

- Custom-built manifold: 316 stainless steel

- Seals: Viton® or equivalent, Kalrez® optional

- Tubing: 1/16 or 1/8 inch 316 stainless steel

Gas flow control

- Control Range 0-200 SCCM

- Turn-down Ratio up to 1000:1

- Calibrated gases N2, CO2, He, O2, Ar

Temperature control

Incubator control

- Controls entire generation and measurement system

- Control Range: 5 °C to 60 °C

- Control Accuracy: ±0.2 °C

Local sample heater

- Control Range: 10 °C to 150 °C

- Control Accuracy: ±1 °C

- Heated diameter: 120 mm

Sample dimensions

- Variable sample diameter

- Standard width 11 cm

- Thickness <0.5 mm

Humidity generation

Water reservoirs

- 50 mL easy-change reservoir

- Heated to prevent evaporative cooling

Generation

Measurement

- Measurement Range 0-100% RH

- Accuracy (5-40 oC) ± 0.8% RH

- Accuracy (40-85 oC) ± 1.5% RH

|

Gas and vapor sensors

CO2 measurement

- 0 – 25% vol, atmospheric pressure

- Accuracy: Exact 3 or 0.05 %vol. of inlet concentration

Organics measurement

- 0 – 98% for 5-60 oC

- Low-range sensor 1 ppb-40 ppm

- Mid-range sensor 0-4000 ppm

- High-range sensor 0-10000 ppm

TCD gas measurement

O2 measurement

- Measurement range 0-100%

- Accuracy (<1% O2) ± 0.02%

- Accuracy (100% O2) ± 2%

WVTR measurement

- (80 cm2) 0.05 – 500 g m-2 day-1

- System Information

- Dimensions: 520 mm (W) × 980 mm (H) × 610 mm (D)

- Weight: 80 kg (180 lb)

- Electrical: 200 – 240 v, 50/60 Hz, 1500 VA

System software

Instrument control software

- Several component permeation and detection

- Numerous concentration or temperature cycles

- Temperature changes in a single experiment

- Live data view and plotting

- Full control over parameters

- Powerful custom methods and sequences

MPA analysis software

- Calculation of water vapor transmission rate (WVTR)

- Calculation of diffusion lag time

- Easy graphical plotting

- Permeability calculations

|

Schematics

Image Credit: Surface Measurement Systems Ltd

Standard compliance

The MPA Horizon conforms with:

Oxygen:

- F-1307-20

- F2622-08 (Reapproved 2013)

CO2:

- F-1307-20

- F2622-08 (Reapproved 2013)

H2O:

Bring the power of the MPA Horizon to the lab

Image Credit: Surface Measurement Systems Ltd

The MPA Horizon is the preferred device for accurate cross-flow analysis of films and membranes.