Key trends shaping pharmaceutical manufacturing

Challenges facing the industry

References

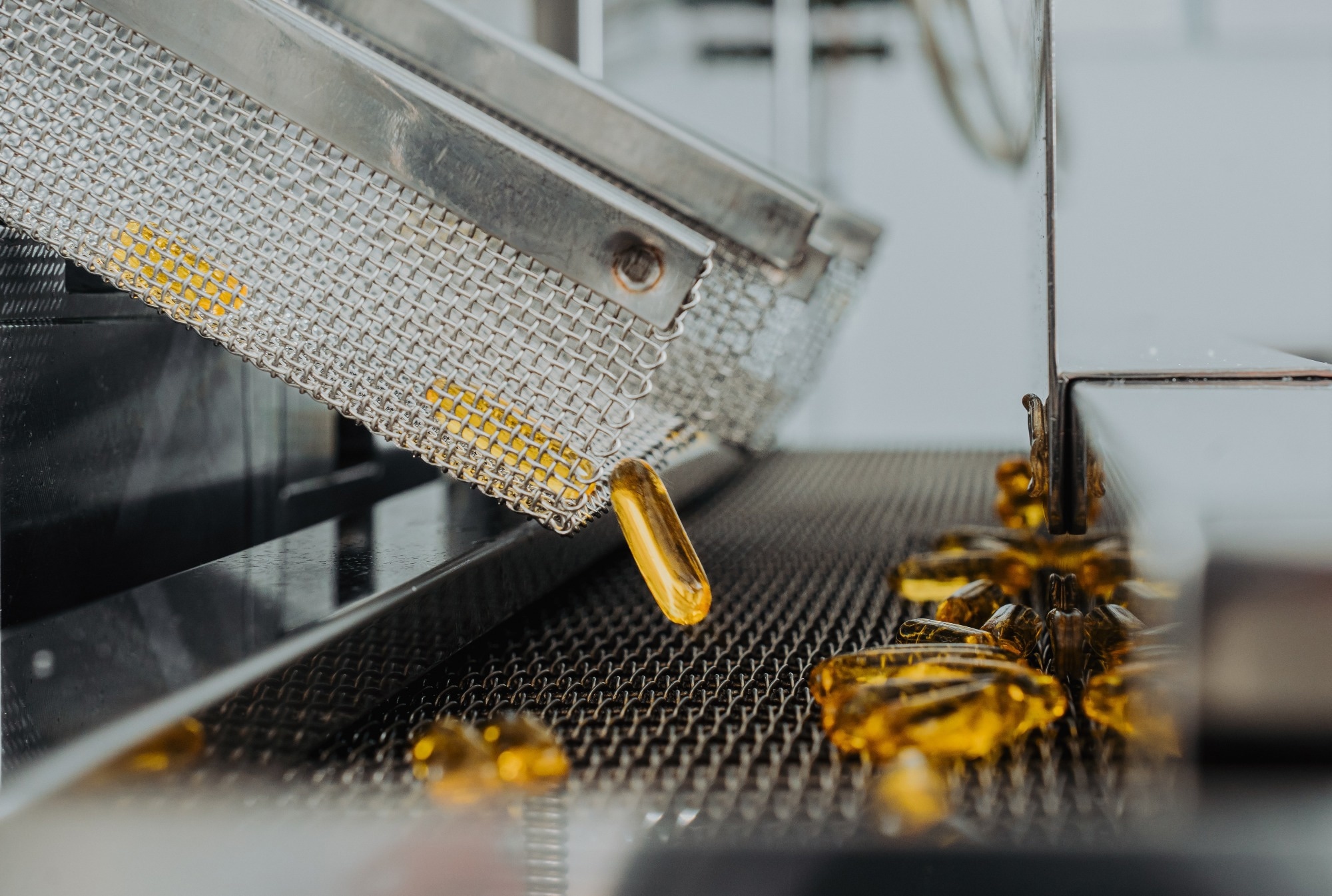

Pharmaceutical manufacturing encompasses all processes involved in the manufacturing and production of biological and medical products, botanical drugs, and herbs, as well as other pharmaceutical products used for internal consumption, such as tablets and capsules, as well as those used for external applications, like ointments.1

In 2024 alone, the pharmaceutical and medicine manufacturing market was estimated to be worth over $1 billion USD, and it is expected to continue expanding to a valuation of over $2.5 billion USD by the end of 2034.2

Image Credit: Ann Rudova/Shutterstock.com

Image Credit: Ann Rudova/Shutterstock.com

Key trends shaping pharmaceutical manufacturing

Mergers and acquisitions (M&A)

M&A plays a key role in bringing highly lucrative medications to market, as large pharmaceutical companies often look to invest in young biotechnology companies for their innovative products. In 2024, most M&A deals were less than $5 billion USD, which has been largely attributed to smaller biotechnologies taking their own drugs to market rather than relying on investments from larger companies like Pfizer.

Some key biotechnology acquisitions this year included Vertex Pharmaceuticals purchasing Alpine Immune Science and Novartis acquiring MorphySys for $5 and $2.9 billion USD, respectively.3 Despite reduced investments in 2024, experts predict that much larger deals will occur in 2025.

Biosimilars on the rise

Of the 50 different drugs approved by the U.S. Food and Drug Administration (FDA) in 2024, 18 of these agents were biosimilars, eight of which target reference products with no previous biosimilar competition. The most recent biosimilar to receive approval by the FDA is Steqeyma, a biosimilar for Stelara (ustekinumab), which is an antibody therapy used in the treatment of several inflammatory conditions, including plaque psoriasis, psoriatic arthritis, and inflammatory bowel disease (IBD).

Biosimilars are defined as biological products such as therapeutic proteins or monoclonal antibodies that do not significantly differ from an existing FDA-approved reference product.4

After the expiration of a patent for any drug or biologic, the cycle of market-based competition and innovation begins, which allows other pharmaceutical companies to produce biosimilars that are often less expensive and may even exhibit superior properties than the original biologic drug.

Biosimilar Drugs: Overview and Industry Challenges

Outsourcing boom

In 2024, the largest M&A was the Novo Holdings buyout of Catalent, a contract development and manufacturing organization (CDMO), for $16.5 billion USD.3 CDMOs offer a wide range of comprehensive services to pharmaceutical companies, some of which can include supporting formulation development, upscaling current drug processes, clinical trial management, and regulatory support.5

Some of the key advantages associated with CDMOs include reduced costs, as many CDMOs are equipped with laboratory and manufacturing infrastructure that is ready for use. CDMOs also employ highly experienced professionals, many of whom can offer their expertise in navigating the highly complex aspects of the pharmaceutical manufacturing process.

Technological advancements

Over the past several years, significant advancements in both artificial intelligence (AI) and machine learning (ML) technologies have transformed almost every industry, including pharmaceuticals. During drug development, AI has been used to accelerate the identification of potential drug candidates by circumventing conventional screening studies that are often labor-intensive and expensive to perform.6

AI has also been used to predict any defects or other quality deviations during the manufacturing of pharmaceutical products, thereby ensuring the safety, efficacy, and high quality of final products.

As technology continues to advance, the integration of AI into various aspects of the pharmaceutical industry will undeniably drive innovation, improve patient outcomes, and reshape the future of healthcare.6”

Exploring Sustainable Practices in Pharmaceutical Manufacturing

Sustainability in manufacturing

In 2018, the pharmaceutical industry produced over 52 million metric tons of carbon dioxide (CO2) equivalents, with these emissions directly contributed by research, transportation, and manufacturing processes. 7

One of the primary ways in which the pharmaceutical industry has reduced its carbon footprint is by reducing its use of solvents, which are increasingly being replaced with “green solvents,” such as water, ionic liquids, or those derived from renewable sources.

Additive manufacturing (AM), which is more commonly referred to as three-dimensional (3D) printing, allows for the custom design and printing of structures for a wide range of purposes. Within the medical industry, AM has been used to create personalized drug delivery systems and customize drugs based on the patient’s age and health.

AM also offers a more sustainable approach to drug manufacturing, as it can significantly reduce the amount of materials used, as well as the amount of energy and time needed to complete the print.

Continued monitoring of energy and input/output statistics will be imperative for adjusting the applications of technologies to help optimize their sustainable progression.7”

Key FDA Decisions Made in 2024

Challenges facing the industry

The pharmaceutical industry must comply with numerous laws, guidelines, and standards that are enforced by local and federal entities, such as the FDA in the U.S. and the European Medicines Agency (EMA) throughout Europe.

Some of the key regulations that pharmaceutical companies must adhere to include 21 CFR Part 11, which requires all companies to maintain secure electronic records to ensure the integrity of their data, as well as Good Manufacturing Practices (GMP), which emphasizes the need to comply with strict quality and safety standards throughout all manufacturing processes.

The cost of non-compliance varies; however, experts anticipate that the average cost of a single violation will be about $14.8 million USD in 2025. In fact, one of the most expensive violations was reported in 2022 by Sanofi, which cost the company over $190 million USD in fines.8

As regulatory bodies like the FDA are faced with the challenge of updating their regulations to continuously changing technologies, pharmaceutical companies must also ensure that they are abiding by these new drug manufacturing rules. Some of the different ways that pharmaceutical companies can achieve regulatory compliance include the implementation of a strong quality management system (QMS), proactive audits and inspections, regular training of employees, and incorporating automated tools to reduce the risk of human error.

References

- “Pharmaceutical and Medicine Manufacturing Sector (NAICS 3254)” [Online]. Available from: https://www.epa.gov/regulatory-information-sector/pharmaceutical-and-medicine-manufacturing-sector-naics-3254.

- “Pharmaceuticals & Medicine Manufacturing Market Set to Surge at 8.9% CAGR, to Reach US$ 2,516.46 billion by 2034” [Online]. Available from: https://www.globenewswire.com/news-release/2024/12/24/3001650/0/en/Pharmaceuticals-Medicine-Manufacturing-Market-Set-to-Surge-at-8-9-CAGR-to-Reach-US-2-516-46-Million-by-2034-Fact-MR-Report.html.

- “Pharma Has Kept M&A Spending Small This Year, With Just One Deal Topping $5B” [Online]. Available from: https://www.biospace.com/business/pharma-has-kept-m-a-spending-small-this-year-with-just-one-deal-topping-5b#:~:text=By%20far%2C%20the%20largest%20acquisition,than%20%245%20billion%20per%20deal.

- “What biosimilars have been approved in the United States?” [Online]. Available from: https://www.drugs.com/medical-answers/many-biosimilars-approved-united-states-3463281/.

- “CDMO: What Is IT and How It Benefits Your Business” [Online]. Available from: https://adragos-pharma.com/cdmo-what-is-it-and-how-it-benefits-your-business/.

- Huanbutta, K., Burapapadh, K., Kraisit, P., et al. (2024). Artificial intelligence-driven pharmaceutical industry: A paradigm shift in drug discovery, formulation development, manufacturing, quality control, and post-market surveillance. European Journal of Pharmaceutical Sciences 203. doi:10.1016.j.ejps.2024.106938.

- Weaver, E., O’Hagan, C., & Lamprou, D. A. (2022). The sustainability of emerging technologies for use in pharmaceutical manufacturing. Expert Opinion on Drug Delivery 19(7). doi:10.1080/17425247.2022.2093857.

- “Regulatory Compliance for Pharmaceutical Industry: A Comprehensive Guide for 2025” [Online]. Available from: https://www.compliancequest.com/bloglet/regulatory-compliance-for-pharmaceutical-industry/.

Further Reading

Last Updated: Jan 15, 2025