DSM’s biomedical work brings new material innovation to market through the development of novel materials-based solutions that meet the present and future needs of the medical device and pharmaceutical industries.

Current business segments include biomedical polyurethanes, biomedical polyethylenes, resorbable polymers, ceramics, collagens, extracellular matrices, silicone hydrogels, device coatings and drug delivery platforms.

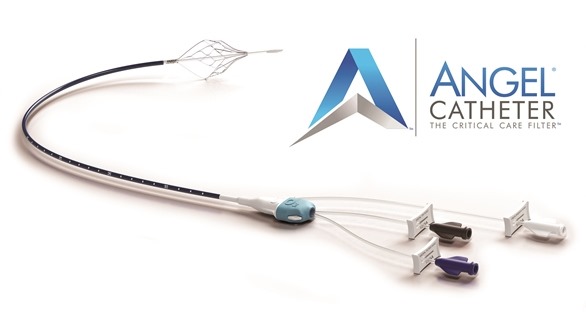

The BiO2 Angel Catheter, which uses DSM's ComfortCoat coating.

Could you please give an overview of the partnership with BiO2 Medical? Why has ComfortCoat® lubricious coating been chosen for use with the Angel® Catheter?

DSM provides its proprietary ComfortCoat® coating to BiO2 Medical for use in the Angel® Catheter.

ComfortCoat® coating is a hydrophilic and lubricious coating that enhances ease of placement and reduces access site trauma by maintaining lubricity during catheter insertion.

It also offers easier maneuverability of the device and reduces damage to the veins and urethra.

The lubricity helps reduce the rate of bacteria that adheres to the catheter, significantly lowering the chance of infection.

BiO2 partnered with DSM due to the Company’s highly regarded coating technology, technical support, responsiveness, and ability to meet project timelines.

What are the important properties and benefits of the ComfortCoat® coating? What further applications can the ComfortCoat® coating be used for?

ComfortCoat® coating helps maintain a hydrophilic and lubricious environment around medical devices. The coating is used on catheters, guidewires, and other devices in vascular and urinary applications where lubricity and water retention are important.

Essentially, any device small enough to be delivered via catheter can benefit, as sometimes these devices need to be navigated through tortuous and narrow anatomies.

Easing insertion of a dilator, introducer sheath, and catheter can lead to more accurate device implantations, increased comfort for patients, and prevention of unnecessary tissue damage.

The Axis Shield Afinion Cartridge, which uses DSM's VitroStealth coating.

What are some of the other coatings that DSM provides?

DSM manufactures VitroStealth® antifouling hydrophilic coating, which reduces unwanted protein adsorption and cellular adhesion on material surfaces, resulting in reduced biofouling on medical devices.

VitroStealth® antifouling coating is mechanically strong, has excellent wettability and is permeable to molecules such as glucose and oxygen.

VitroStealth® coating is primarily used in the diagnostics market in insulin pens and pumps, biosensors (like continuous glucose monitoring), and point-of-care diagnostic cartridges.

Lastly, how do you see the coatings sector advancing over the next 10 years, especially in the biomedical field?

DSM is always following market trends and we stay on top of new developments and ongoing innovations. Generally, we see a trend in the biomedical field towards smaller devices, which will lead to coatings with smaller molecules.

DSM’s coating service plant is equipped to handle a wide range of sizes and geometries of medical device parts and components and we are excited to see what new breakthroughs are on the horizon.

About Dr. Hinke Malda

Dr. Hinke Malda is the Director of Medical Coatings at DSM Biomedical where she leads research, application and product development, and marketing and sales teams that are responsible for DSM’s global medical coatings business.

Dr. Hinke Malda is the Director of Medical Coatings at DSM Biomedical where she leads research, application and product development, and marketing and sales teams that are responsible for DSM’s global medical coatings business.

Dr. Malda has been with DSM since 2006. Within DSM, she served in several positions in research, development and application with increasing responsibilities. In her first role at DSM, Dr. Malda was responsible for a team that designed, synthesized and up-scaled emulsion and urethane polymers. Before starting her role as Director of Medical Coatings, Dr. Malda was a Business Development Manager within the EMEA region and lead negotiations for contracting various large medical device companies.

Dr. Malda holds several degrees including a Masters of Chemistry from the University of Groningen and a Ph.D. in Chemical Engineering and Biomedical Engineering from Eindhoven University of Technology. She is a co-inventor and co-author of several patents and scientific publications.