Collaboration between Primasil Silicones and its academic partner University of Huddersfield has enabled Paxman™ to bring relief to cancer patients undergoing chemotherapy by further reducing the risk of hair-loss during treatment.

The latest innovations in development are being designed to improve the effectiveness and availability of the cooling cap which Paxman first developed in the late 1990s with help from Primasil. Their main challenge this time was to create a new silicone rubber formulation that would give the reusable cap greater flexibility to adapt to varying head shapes and sizes around the world. In addition, the partners looked at ways of increasing automation in the cap’s production to satisfy increasing demand for the product.

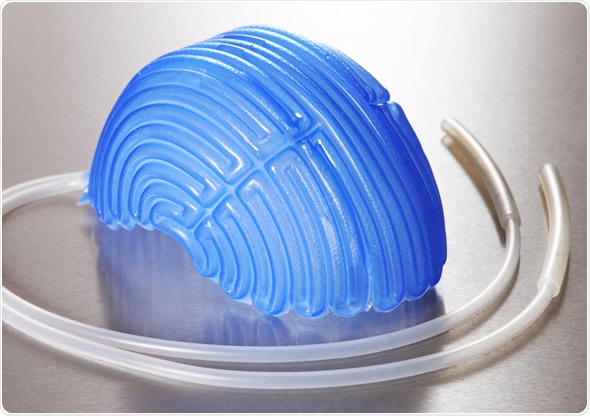

Chemotherapy affects rapidly dividing cells, which include most of our hair follicles. Its unintended consequence can be atrophy of the hair root bulb. The Paxman cooling cap essentially consists of a compact refrigeration system connected to a lightweight silicone rubber cap. By lowering the head and scalp temperature, immediately before, after and during treatment, it reduces blood flow to the follicles and so prevents or minimises damage.

“Primasil silicone’s rubber experience in the medical industry and its understanding of, quality standards and certifications has made them an invaluable partner in both developing and improving the cooling cap,” Richard Paxman, Managing Director, Paxman Coolers explains.

Medical innovation is not just about curing illnesses, it also helps the treatment process. In the case of chemotherapy, hair loss can have a devastating effect on a patient’s self-image and confidence, which is why the Paxman cooling cap was originally developed and launched to the market in 2000.

Primasil Managing Director Steve Wheeler, comments, “Our latest joint efforts have produced a better fitting cap which ensures that the coolant running through it is always in close contact with the scalp, all over the head and throughout the treatment. We also now have a more automated manufacturing process that allows increased efficiency and higher volume supply in response to market needs and opportunities.

“Silicone rubber is a remarkable material which is flexible in every sense of the word. Through subtle alterations of its chemistry we can bend and shape its properties to meet most needs, and when the right minds are brought together our potential for creating, improving and transforming medical devices is almost limitless,” he concludes.

For further information on Primasil Silicones’ products and services, visit www.primasil.com For details of Paxman, the leading global manufacturer and supplier of scalp cooling equipment for cancer chemotherapy patients, visit www.paxmanscalpcooling.com

About Primasil Silicones

An impressive track record for creating innovative and perfectly tailored solutions has made Primasil Silicones Europe’s leading independent manufacturer of silicone and organic rubber products. Customers are assured that all materials formulated will meet their precise business requirements. Materials can be supplied for use in the customer’s own manufacturing process or converted into finished products using Primasil’s extensive moulding and extrusion plant. Working across industries, worldwide, Primasil’s market-leading expertise is combined with its exceptional quality and service standards, facilities and flexibility to deliver the latest silicone technology and the perfect fit.

Source: www.primasil.com