Nov 18 2016

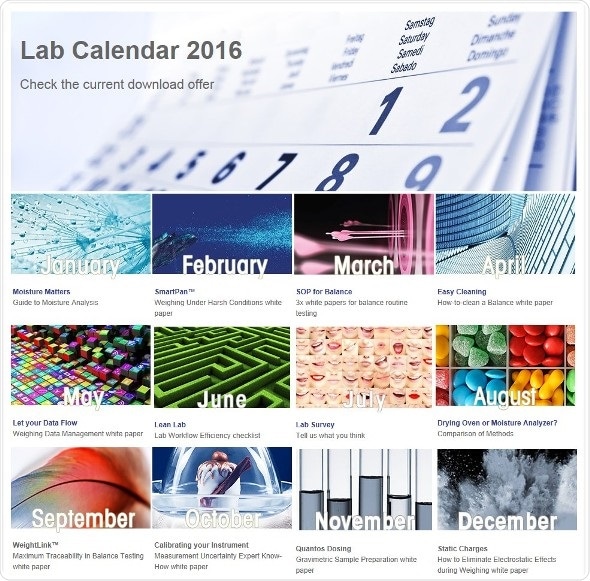

A gravimetric approach to sample preparation can increase accuracy while reducing material use and costs. Learn how in a new, free white paper from METTLER TOLEDO, available only in November as part of the world-renown lab equipment manufacturer’s 2016 e-calendar.

Out-of-specification (OOS) results can have a significant impact on the profitability and even reputation of a pharmaceutical or biotech company. Yet workflows to prepare samples manually, which rely on volumetric flasks and subjective meniscus reading, have not changed significantly in nearly 100 years.

During this time, however, substances being measured have become more refined, potent, hazardous to handle, and often more costly to procure. Pressure to bring products to market faster has heightened and the cost of disposal for unused solutions has increased, as municipalities the world over become more aware of their impact on the environment.

Gravimetric sample preparation (GSP) offers a solution to issues of accuracy, speed, and waste. Solids and solvents are dosed into small, disposable vials on analytical balances to prepare specific, precise concentrations by weight, minimizing or eliminating out-of-specification errors using a method that is much faster than spatulas and funnels. Additionally, GSP enables preparation of just the amounts needed rather than being dependent on larger flask volumes, thus reducing waste and disposal costs.

A new white paper from METTLER TOLEDO, entitled “Quantos Dosing: Gravimetric Sample Preparation”, explores how GSP promotes greater accuracy on an ongoing basis than even the most consistent human operator using volumetric methods. Coupled with enhanced operator safety, reduced environmental impact, and valuable time, resource and monetary savings, as well the benefits of gravimetric preparation, become difficult to overlook.

To learn more about how GSP can help improve sample and solution preparation accuracy while saving time and resources in lab processes, download “Quantos Dosing: Gravimetric Sample Preparation” in November.

December’s final installment of METTLER TOLEDO’s 2016 e-calendar will help further optimize lab processes for greater accuracy, so keep watching for additional information.