An interview with Richard Harvey, Medical Group Leader, Hamamatsu, conducted by April Cashin-Garbutt, MA (Cantab)

Can you please give a brief introduction to silicon photomultipliers (SiPM) and their use in medical imaging?

The silicon photomultiplier, or SiPM, is a solid state detector representing the next generation of photon counting detector that can be used in medical imaging.

Traditionally, medical imaging modalities such as PET were carried out using photomultiplier tubes (PMT), which are a glass vacuum tube technology and have been in production since the ‘50s. This next generation of photo detector instead uses silicon and this brings many advantages.

One of the key benefits to medical imaging that we are seeing is that the SiPM is insensitive to magnetic fields. This means that you can combine a PET detector with an MRI detector and use them simultaneously in multimodality imaging.

This cannot be done with a PMT because electrons inside the glass tube are affected by the high magnetic field, affecting their trajectories through the dynode chain. If the electrons impact in the wrong place, the signal is completely destroyed. Because the silicon photomultiplier is insensitive to magnetic fields, a PET ring can be used inside the MRI machine.

The early generation PET systems were known as ‘clip-ons’, and were used in pre-clinical research. Here the PET ring would be attached to the front of the MRI machine. However, the next generation will be ‘up the bore’ where the PET ring is fully integrated in the scanner. This is one of the key areas of PET development at the moment.

The SiPM can also be used in SPECT, which is the most commonly adopted imaging modality, and again this has been the home of PMTs in the past. Additionally, it is possible to combine SPECT with PET and MRI.

How have SiPM products advanced over recent years?

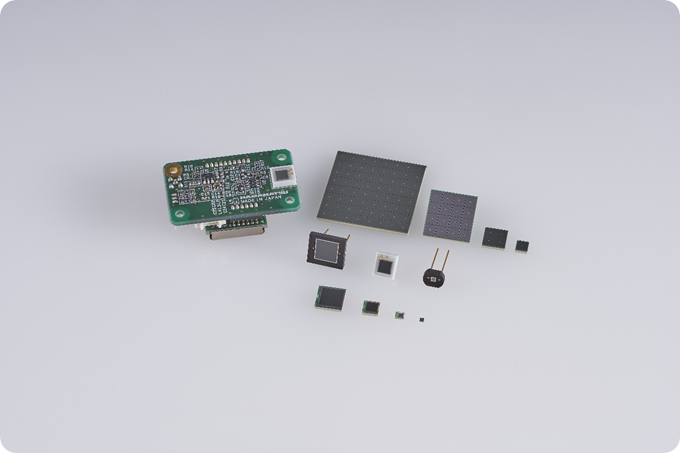

The technology has been around on paper for decades but the manufacturing techniques took longer to develop. Hamamatsu has had SiPM detectors (which we call MPPC for Multi-Pixel Photon Counter) commercially available since early 2007.

The first generation of SiPM was adopted by high energy physicists working at the T2K experiment in Japan and later the Large Hadron Collider at CERN in Switzerland. They were able to utilize the benefits of these detectors at a very early stage, but they weren't yet suitable for commercial use in the medical environment.

Over the last 10 years, there have been multiple generations of these detectors released. With each generation there has been an improvement in the fill factor, sensitivity, reduction of afterpulsing, crosstalk and also in the dark count rate. All of these different parameters contribute to the overall performance of the detector.

Fill factor is a very important parameter because the detector itself is made up of many small pixels ranging from 10-100μm in size. Each one of these small pixels is an avalanche photodiode operated in Geiger mode and all are connected to a common output.

A certain proportion of the available silicon is taken up by the detector’s architecture including quenching resistors on each pixel. The fill factor is telling you how much silicon is available to detect light, compared to how much silicon there is in total. So it makes sense that the higher the fil factor, the better the detector will perform. The current fill factor can be as high as 82%, and that has increased from 60% in the first generation of detectors.

For time-of-flight PET (TOF PET), afterpulsing is an important factor and the detector technology is being improved in this area too. An afterpulse is created when a charge carrier generated by a photon is trapped in the silicon crystal lattice and is then released after the main photon event. The afterpulse will look like another photon has arrived and can lower the resolution of timing based measurements. The afterpulse rate in the first generation of detectors was very high, close to 100%, but today this has been reduced to less than 3%.

At the same time crosstalk has also been reduced. Crosstalk occurs due to the pixelated structure of the SiPM. If a pixel is triggered by a photon, an adjacent pixel may fire as well. Similar to an afterpulse, this will look like the detector has measured two or more photons rather than the one photon that was incident on the detector. Crosstalk is reduced with an advanced wafer processing technique that adds trenches around each individual pixel. This process reduces crosstalk from approximately 50% to less than 2%. These two improvements mean that in current generations, afterpulsing and crosstalk can be ignored in most general applications.

The final parameter that has been improved is the dark count rate. There has been approximately a 20 times improvement in dark count rate since the first SiPM detectors were released in 2007. Again, we are now at the point now where in many applications the dark count rate can be effectively ignored. The technology has come a long way over the different generations.

Since the Hamamatsu MPPC SiPM was released we have offered integrated detector modules. Today this range of modules has expanded further and we now offer complete assemblies for PET and TOF PET. These modules include the detector array, scintillator crystals (also manufactured by Hamamatsu), ASICS and all associated drive electronics.

This is one of the ways that Hamamatsu is trying to differentiate itself from competitors, by utilising all of our, often unique, in-house technologies.

What challenges still need to be overcome and how do Hamamatsu plan to assist?

We regularly hear from users that the Hamamatsu SiPM detector is the best on the market in terms of performance. There is always room for improvement and so this means going back to the areas I mentioned in the previous question. Fill factor is one of the key areas to continually improve, as you need to make sure as much of the silicon in your detector as possible is capable of measuring light. Dark count rate, crosstalk and afterpulsing will also be further improved in future generations.

Today different detectors are being released with an extended different spectral response. Soon we will have a near-infrared (NIR) SiPM tailored towards different application areas. In this case an NIR SiPM is ideally suited to laser range finding (LIDAR) in the automotive industry, where there is vast amounts of R&D underway working towards self-driving cars.

The SiPM technology itself is now matured to an advanced stage. Several years ago, when doing a Google Scholar search, you would find a high number of papers detailing improvements made in the technology. Whereas performing the same search today will reveal that the majority of papers are discussing the applications that can use the SiPM. This is an important shift and shows how the SiPM has been accepted by the market.

Is SiPM a good technology for point of care?

The whole premise of point of care is that it needs to be low cost, in some cases disposable, compact, reliable and simple to use. Point of care has been discussed for many years and it is now becoming a reality. The Hamamatsu PMT has always been a contender for point of care, but it is often slightly larger and more expensive (although there is much progress in the PMT technology field today as well).

The PMT is still the gold standard for low light detection, but in many cases in the point of care environment a silicon photodiode, APD or an SiPM can be used. Using a semiconductor detector will usually give some benefit in terms of size and cost. Today we are seeing a marked increase in enquiries from the point of care sector, and more often than not for the SiPM.

Hamamatsu can offer complete OEM detector modules that can be easily integrated in to various instruments in a production environment. At the development stage we can also provide the customer simple but powerful evaluation circuits which allow them to get up and running very quickly.

The SiPM is an enabling technology in the point of care field, which at this stage is unrivalled in terms of cost to performance ratio.

What other techniques can be used?

Hamamatsu is in an excellent position whereby we can offer multiple technologies to a customer. This means that we can select the most appropriate detector technology for their measurement and are not tied to any particular detector type.

In terms of increasing sensitivity with semiconductor detectors we start with simple silicon photodiodes, moving avalanche photodiodes (APD) and finally the MPPC SiPM. APDs are typically used in high speed applications such as LIDAR but, can also be found in other areas such as ophthalmology.

The other major technology used today is the Hamamatsu micro-spectrometer. The benefit of the micro-spectrometer, compared to the SiPM, is the fact that it will output spectral information. The SiPM covers a broad spectral range, approximately 320 to 900 nanometers, but the only information gathered by the detector is the number of photons incident on the detector. In a measurement with a broad spectral output, without filters it is not possible to know what wavelength these photons were. The micro-spectrometer will break down the input light via a grating and CMOS image sensor, telling you how much light of each wavelength was received over the range from 340 to 950nm.

Micro-spectrometer

By looking at the spectrum of your signal, you could identify multiple fluorescence markers simultaneously. This can be achieved with a single compact detector which is now fingertip size. To achieve this with a SiPM or similar detector the user would need either multiple excitation sources, multiple detectors or filtering, so increasing the cost of the detection system.

For point of care, the micro-spectrometer is a very important product. Although the sensitivity is not as high as the SiPM, the low cost alongside the rich spectral information make the micro-spectrometer a key enabling technology for point of care.

What do you think the future holds for silicon PM in medical imaging?

The SiPM is now being widely adopted in PET and SPECT, so the future of the technology looks very strong. As the technology continues to improve, the transition speed from PMT to SiPM will likely increase. However, we think there will still be a place for the PMT in the future as it does offer some key advantages. The SiPM is going to be the technology of choice particularly for medical imaging though.

MPPC SiPM

What is Hamamatsu’s vision for the future?

On our website, we have an area called “Life Photonics” and this details some of the key areas that we feel will be impacted by photonics over the next twenty to thirty years. The path to a sustainable future is not without obstacles. At Hamamatsu, we believe that photonics technology can provide the means to overcome many of these challenges, in areas such as healthcare, medicine, energy, and the environment. All of these facets of life fall under our research & development theme of Life Photonics.

Across the company we are looking at grand long term technologies such as laser fusion whilst also more immediate medical device development. Hamamatsu invests between 10% and 15% of our annual turnover back into R&D activities across the company.

We have a centre called the Central Research Laboratory in Hamamatsu City as well as the Graduate School of Photonics, which is similar to a small university purely focussed on photonics and its application.

Hamamatsu Photonics definitely sees itself firstly as a technology company.

How do Hamamatsu differ from competitors in this space?

Hamamatsu is a very customer-relationship focused company. We prefer to work closely with customers, large or small, assisting them through their development process and eventually becoming a strategic partner with the organisation going forward. It is not uncommon for a customer to use their relationship with Hamamatsu as a selling point for their own technology or product.

Hamamatsu looks, where possible, to supply a complete solution and not just a component. In medical imaging for example, we will manufacture the scintillator crystal, the detector and the control electronics for a detector assembly. All of which can be mounted in a custom housing. Our ability to offer a tailor made solution we feel is what differentiates us most from other competitors.

Another way in that we are different from our competitors is that we provide a huge variety of product ranges. This not only includes PMT and SiPM but also lasers, LED, image sensors, lamps, complete end user camera systems and products sold directly into the medical field. The actual number of products we can offer is in the thousands and nearly all are developed in-house.

Due to this wide product range, we often have multiple solutions for a single problem. This means that a customer has much more choice and, because we understand the multiple technologies on offer, we can help them to choose the best technology for that customer’s needs.

Where can readers find more information?

Our website: http://www.hamamatsu.com

About Richard Harvey

I joined Hamamatsu in 2007 after studying for a masters in physics at the University of Birmingham. Being able to work in a business environment whilst still using knowledge gained during my degree course was very attractive.

I joined Hamamatsu in 2007 after studying for a masters in physics at the University of Birmingham. Being able to work in a business environment whilst still using knowledge gained during my degree course was very attractive.

In 2009 I became a field based Sales Engineer focusing across all application areas and also responsible for sales into Ireland.

In 2015 I was promoted to be the Medical Group Leader. In this new position I am responsible for developing and increasing the medical and healthcare related business for Hamamatsu in the United Kingdom and Ireland.

This includes responsibility for all sales, business development and a deep input in marketing and promotional activities.