Global engineering and healthcare technologies company, Renishaw, is attending the British Association of Oral and Maxillofacial Surgeons (BAOMS) Annual Scientific Meeting at the International Convention Centre in Birmingham, UK. The conference is taking place between June 28th - 30th, as a platform for surgeons and industry professionals to present the latest research and development in the field.

The company will present its latest developments in craniomaxillofacial implants and support a workshop run by three surgeons with whom it has collaborated. Renishaw can be found on stand 15.

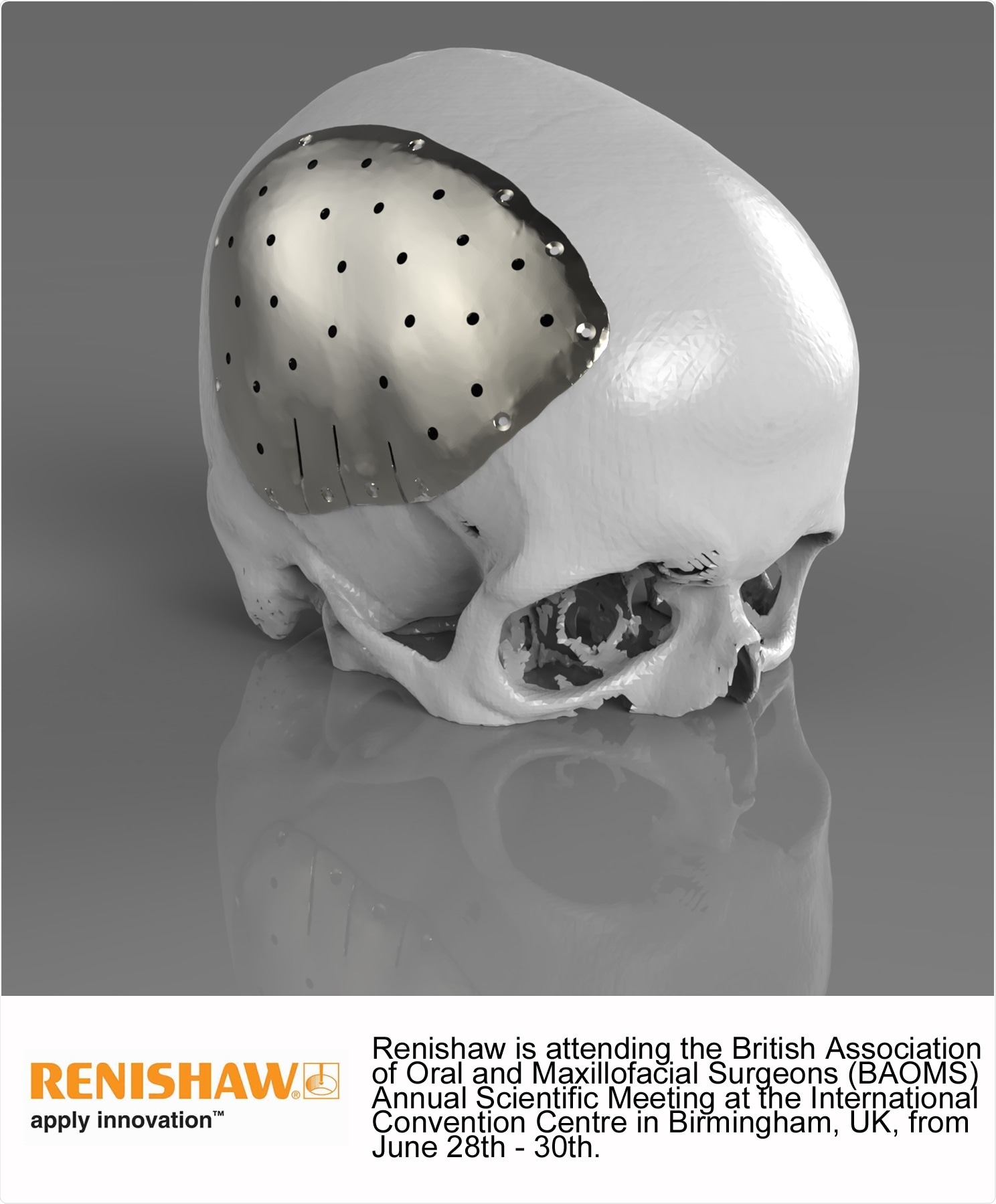

This year marks Renishaw’s third appearance at the conference, where it will be exhibiting additively manufactured implants and guides. The implants are designed using information acquired from a patient’s MRI or CT scan, produced on a Renishaw additive manufacturing system and offered in three finishes; clean, satin and mirror. The implants and guides can be used in many oral and maxillofacial applications.

Renishaw’s stand will feature demonstrations of its new implant design software, ADEPT, to show first-hand how easy-to-use the software is and how it can improve a hospital’s working practices.

The company is supporting a workshop run by three surgeons that have used implants manufactured with Renishaw’s metal 3D printing technology in surgery. The session will focus on the use of metal 3D printing, skull base access and providing patient specific solutions, based on the experiences of the surgeons and cases they have been involved in.

“3D printed implants and guides are still considered a relatively new technology for craniomaxillofacial applications,” explained Ed Littlewood, Marketing Manager at Renishaw’s Medical and Dental Products Division. “However, a growing number of UK NHS hospitals are now using additive manufacturing to improve predictability, efficiency and safety. An increasing number of surgeons are commissioning the design and production of additively manufactured bespoke implants and guides.”

Additive manufacturing technology can be used by hospitals to improve patient outcomes and speed up surgery. The benefits to the patient, surgeon and team can be a powerful motivation for hospitals to make a change and adopt the technology”

Amy Davey, Reconstructive Scientist at North Bristol NHS Trust

“The workshop will help give surgeons experience and confidence using patient specific implants and will demonstrate meaningful evidence of their success,” continued Davey. “Ultimately, this will help in the goal to improve patient outcomes by making additive manufacturing technology more accessible and widespread.”

Renishaw is a world leading engineering and scientific technology company with expertise in additive manufacturing, precision measurement and healthcare. It is the only UK manufacturer of metal additive manufacturing machines.