An interview with Dr. Heidi Grimmer, Head of Flavor Stability Team FlavorActiV.

What are the main challenges when optimizing beer’s shelf life and achieving flavor stability?

The main challenges in optimizing beer shelf life is that most manufacturers can only perform accelerated shelf life testing on packaged beer. So, it's almost impossible to determine where in the process you've had a positive or a negative impact on the freshness of the beer.

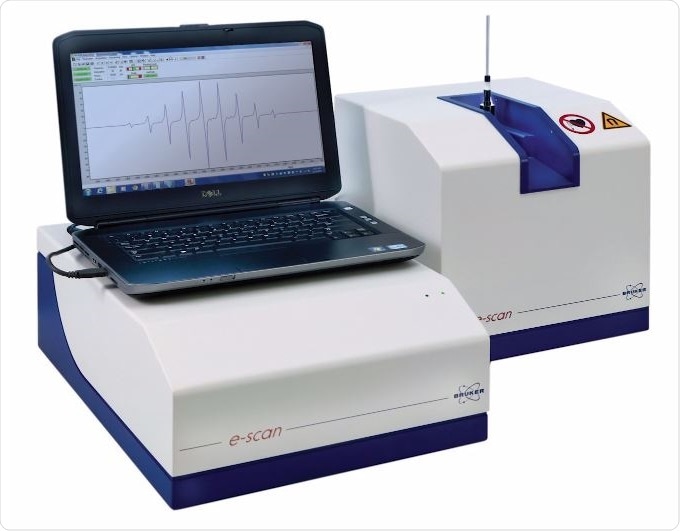

That's where benchtop EPR becomes useful, because one can look at each step of the process to see where one could improve the beer shelf life.

Benefits of Benchtop Electron Spin Resonance

How important is freshness to manufacturers and consumers?

The focus needs to be on the consumer, because the consumer enjoys the beer. It's about creating beers that are fresh, drinkable, and that are sessionable.

Consistent experience is also important. Beers that are made inconsistently have a major impact in terms of the freshness. The compounds that give rise to the off-notesss and lack of freshness are trans-2-nonenalites - a dominant compound that appears in beer.

What compounds give rise to the “cardboard like” flavor of stale beer? What causes these flavors?

The cardboard like flavors are predominantly oxidative flavors, so one of them is trans-2-noneal which is a typical cardboard flavor, and that doesn't make the beer very sessionable and is one of the reasons people don't enjoy the beer because it just becomes very bitter.

Benchtop EPR measures free radicals, which are things that make us, and beer, age. We look for the rate of free radical formation in the beer which allows us to measure the lag time and we use the rate of formation to tell us about the shelf life of the beer.

The faster the rate of radical formation in the beer, the faster the beer ages. We then try to optimize our raw materials and our brewing process, such that we optimize the antioxidants in that beer. This can reduce the rate of radical formation in our beer and hence increase the shelf life and beer freshness.

Why is FlavorActiV focusing on electron spin resonance (ESR)?

FlavorActiV is the global leader in the supply of GMP standards, training panels and proficiency in quality control environments. It's important to be able to link some of the tasting to an analytical method, particularly because a lot of the tasting can't happen in process, but only in packaged beer.

Working with Bruker allows us to bring the technology together with sensory feedback as a two-way approach to ensuring beer freshness.

Can you please explain how the lag time assay works?

For a lag time assay we simply take a beer - or an in process sample, and add a compound called PBN, which is a spin trap. It traps the radicals and - forms a steady radical adduct which we - measure over time.

During the assay, we will plot the increase of concentration of the radicals and from the graph calculate the lag time, which is then related to the shelf life of the beer.

Benchtop EPR technology enables you to measure anything from - malting all the way through to wort cooling, fermentation, maturation and packaged or kegged beer.

At each point, you identify those steps in the brewing process that either impact positively or negatively on the brewing process, and hence you are - able to measure how that improves your beer freshness and the enjoyment for the consumer.

Most other analytical methods have a limitation to what you can sample and what you can analyze. With benchtop EPR you can go all the way through the process to the packaging. So, it's one of the technologies that allows you to sample throughout, creating good fingerprint of the beer freshness throughout its process.

The important approach is to identify and then to fix. It's about finding the critical points in your process that you then measure in your packaging for example increasing the fermentation rate, or increasing the dissolved oxygen, and answering “how does that impact the beer?” It's about identifying and making sure that once you have measured and identified the critical point that it stays fixed.

It's important because brewing is a multi-step process, and we need to ensure that the interventions that maintain consistency are identified and are always consistently adhered to and monitored in detail. There have been applications for wine producers but they haven't been as developed as the beer market, however I think there's a future for it.

Is that because of the particular peculiarity in the market for beer?

Beer is quite a complex matrix with some interesting chemistry. We have seen applications for fruit juices,. Whether you could do it with a simple beverage, I don't know, but that needs to be tested.

I think there are some exciting developments happening with Bruker and we have seen some of the new developments in software. Simply by making it easier in terms of the user interface and being able to compare different brewing sites.

This means that when breweries have multiple instruments on the site for different things, it makes it easier to be able to compare them directly. That's been part of the challenge. It's not an accredited method, either as an EBC or ASBC accredited method. People don't know what the standard on which we measure is

About Dr. Heidi Grimmer

Dr Heidi Grimmer heads up flavor stability at FlavorActiV. Dr. Grimmer focuses on how FlavorActiV can support their customers to apply benchtop EPR to improve their beer shelf life and freshness.

Dr Heidi Grimmer heads up flavor stability at FlavorActiV. Dr. Grimmer focuses on how FlavorActiV can support their customers to apply benchtop EPR to improve their beer shelf life and freshness.

She is a biochemist by training and has been involved in flavour chemistry as a flavourist at Givaudan, and subsequently as a research scientist during her time at the former SABMiller. Dr Grimmer is experienced in both technical and consumer sensory research.