Delivering Cost Savings, Reducing Waste and Standardizing Workflow

Beckman Coulter Life Sciences expands its global services to flow cytometry customers by placing its DURA Innovations dry reagent solutions at the heart of its enhanced external business resources for laboratories. The dry, unitized reagent assays are available from LUCID custom design and cocktailing services (CDS), or in bulk through RESOURCE contract manufacturing services (CMS).

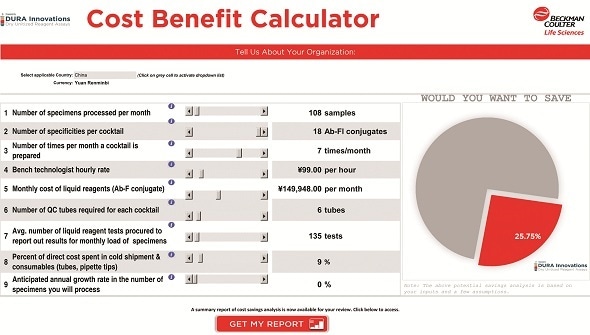

Cost Benefit Calculator. Image credit: Beckman Coulter

DURA Innovations underpin all Beckman Coulter’s dry reagent solutions including ClearLLab.They are highlighted at the 70th American Association for Clinical Chemistry (AACC) Annual Scientific Meeting and Clinical Laboratory Expo (CLE), being held July 29 - August 2, 2018 in Chicago. Beckman Coulter Life Sciences, part of the Danaher Corporation, is exhibiting on booth #3612 alongside Beckman Coulter Diagnostics (another Danaher company).

The multicolor pre-formulated options standardize flow cytometry workflows, helping the lab simplify sample preparation, by reducing preparation time and reagent waste. Using dry, unitized antibody combinations makes it easier to reproduce results and include single color compensation tubes for greater accuracy. Ready to use panels eliminate errors caused by manual antibody pipetting, and also simplify inventory management. Supplies of the tube kits are easy to ship or transfer between labs because they can be stored at room temperature, unlike liquid reagents.

Delivering Efficiency to the Flow Cytometry Lab

Dr. Mario Koksch, Vice President and General Manager of Beckman Coulter’s Cytometry Business Unit, said:

Scientists using flow cytometry techniques are resources of talent and need to free up their time to focus on investigations – not having to create antibody cocktails.

Dura Innovations solutions deliver greater efficiency while ensuring they have confidence in delivering high quality, reproducible results – and that that they will be compliant with current exacting standards.”

The challenge for flow cytometry labs is how to reduce waste and streamline workflow to achieve greater efficiencies, while improving overall quality. Beckman Coulter research indicates that a significant amount of time spent on preparing cocktails could be avoided if a more efficient approach was adopted, especially to sample preparation. It also shows that on an average 25% of the reagents used in the lab are wasted due to factors such as errors, supply expiry, spillage and internal quality control requirements.

Dr Koksch added:

Through the technology of DURA Innovations, and the resources we provide, we are able to demonstrate that producing in-house cocktails is no longer the most efficient way to save time and costs. In contrast, we are able to offer customers choice and flexibility, tailoring a service exactly to their requirements, from small quantities to high volume throughput demands.”

Reagents account for around one quarter of all lab expenditure and there is increasing pressure to cut overall costs. Beckman Coulter provides flow cytometry customers with the DURA Innovations Cost Benefit Calculator Tool so that they can analyze areas of waste in their lab. The Cost Benefit Calculator places the emphasis on helping the lab achieve greater efficiencies by identifying at least eight significant sources of waste. Examples are the number of times a month a cocktail is specially prepared, the amount spent per month on liquid reagents and the cost of shipping refrigerated supplies.

DrKoksch explained:

For example, manually mixing large quantities of cocktails, say 10 specimens with single color panels, would take approximately four hours from sample receipt to first results. In contrast, our RESOURCE service would deliver the panels ready mixed to the lab’s specific requirement, completely eliminating both labor costs and reagent waste.

The DURA Innovations Cost Benefit Calculator Tool enables customers to see for themselves how certain practices they have taken for granted actually increase waste and reduce efficiency by hindering workflow.

The lab can then identify exactly the right way of sourcing their antibody cocktail requirements to remove this waste. Initially, some labs had under estimated problems caused by wastage and manual errors but when they used the business tool and calculated this for themselves, they were surprised at the impact on overall productivity and performance.”