Researchers at the Institute for Bioscience and Biotechnology (IBBR) in Maryland in the U.S. have taken the first step towards developing a method for the production of a standardized monoclonal antibody (mAb).

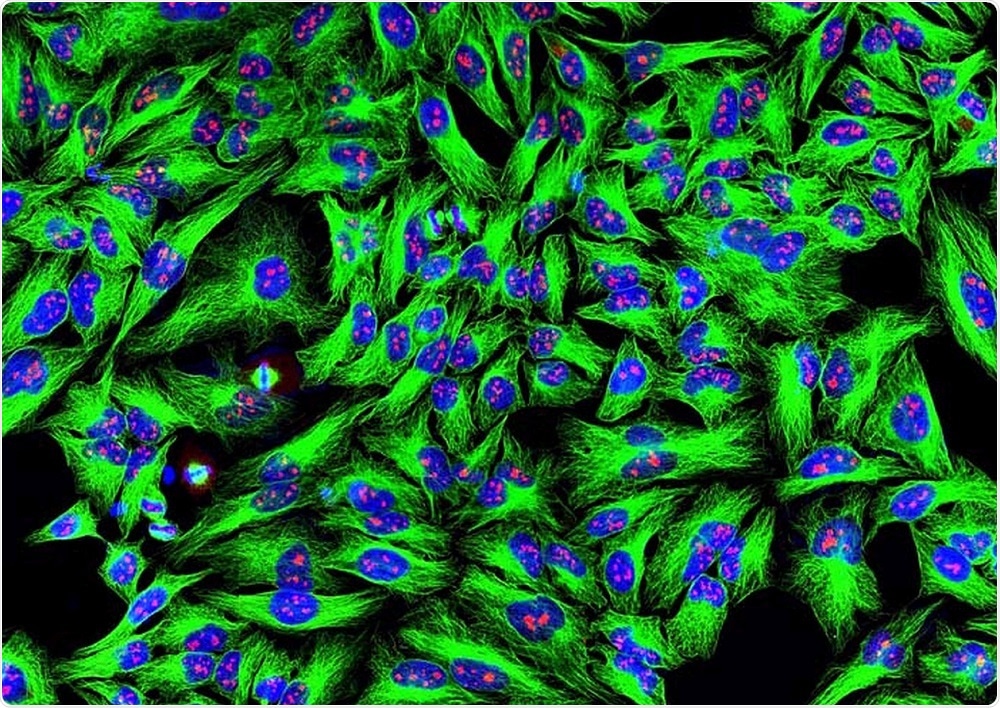

©EnCor Biotechnology Inc

©EnCor Biotechnology Inc

Study author Zvi Kelman says that by developing a way of producing the antibody, called NISTmAb, they can make the measurements that will define the production process.

Monoclonal antibodies are synthesized proteins that are designed to specifically target diseased cells, pathogens and other antigens for removal from the body. They are also used to deliver dugs or radiation to specific sites in the body.

The drugs have had an astonishing impact on medicine and today five of the ten most commonly sold pharmaceuticals are mAbs.

As patents on these mAbs expire in years to come, many biopharmaceutical companies will want to release generic versions (called biosimilars) of the original mAbs.

Both the manufacturers and FDA regulators of the biosimilars must confirm that they match the originals in terms of effectiveness, quality and safety.

In July 2016, the National Institute of Standards and Technology, issued the world’s first standardized mAb which was intended to help verify the quality of measurement techniques used in the development of biologics for a wide range of health conditions.

While the drug itself has been well characterized, the proprietary method used to produce it has not.

As reported in the journal mAbs, the IBBR researchers have now engineered three cell lines to produce non-propriety versions of mAb that closely match the characteristics of the original drug.

Having a rigorously characterized mAb production process, along with our standard NISTmAb protein, will serve as powerful benchmarking tools that should help manufacturers and regulators release new mAb therapeutics and biosimilars with greater confidence."

John Marino, Co-author

Source

https://www.eurekalert.org/pub_releases/2018-07/nios-ncl073118.php