News Medical Life Sciences discussed how lab automation can improve the efficiency of biome research with Tom Copeland, Sales and Marketing Coordinator of Hudson Robotics, at Pittcon 2020.

Could you give our readers an overview of Hudson Robotics and the solutions you provide?

We manufacture automated pipettors, reagent dispensers, microplate washers, magnetic bead solutions for purification and extraction, and positive pressure filter plate solutions for purification and extraction.

Then on the microplate handling side, we have three different types of robotic arms for moving microplates to different instruments in a workcell. Hudson manufactures LabLinx which uses microplate stackers and tracks to deliver plates to instruments in a workcell to create an assembly line process.

We also have three different types of colony pickers. A single-pin tungsten colony picker, mainly for bacteria such as E. coli or yeast. It'll pick between 200 to 250 an hour. We have a second unit that has 20 pins, it looks a little bit like a Gatling gun, that will pick between 2400 to 3000 an hour, including having a robotic arm to move plates in and out of the source and inoculation nests. Hudson’s Harvester uses pipette tips for picking fungal samples and stem cell clusters.

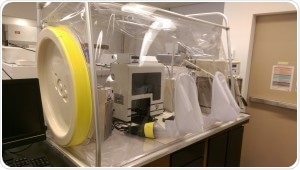

The beauty of these instruments is that they are small. Because of their size they fit in anaerobic chambers or custom biosafety chambers.

The RapidPick SP in an Anaerobic Chamber. Image Credit: Hudson Robotics

A lot of people we work with need a type A, class two biosafety chamber to put their instruments in, and our instruments are small enough to build workcells in these chambers.

Then there's the Rapid_pH robotic pH meter, which is mainly used in the formulations department. It just allows you to walk away to do other work. pH testing is a time consuming, tedious process.The Rapid_pH allows you to select the wells on a microplate that you want and when you come back the pH measurements are finished.

What are the industrial applications of Hudson Robotics’ instruments?

Currently there is a lot of interest in using our instruments for COVID-19 testing and COVID-19 testing kit manufacturing. Some of the applications we work with are ELISA, Microplate coating workcells for ELISA protocols, RNA purification and extraction, DNA purification and extraction, serial dilutions, DNA and RNA normalization, NGS library prep and Zebrafish studies.

Lab automation can be applied to almost any scientific application because the overall benefit is the repeatability, precision, and data tracking that robotics provide.

The software allows you to import data to affect how the robot is going to work and export reports. When you're doing hit picking, you may be pulling data from a reader, and based on that data you're going to then transfer positive samples from one plate to another.. Robotics basically frees up time in a scientist’s day, and provides higher through-put that people can't do, as well as run a system for more than eight hours a day.

Why is lab automation helpful for Microbiome research?

In the microbiome space, our main niche is gut microbiome. You're dealing with anaerobic chambers where there is no oxygen in the chamber. A simple thing like colony picking, since it is in a chamber, would require having to look through glass, or a plastic film which is part of the chamber.

If your hand is in a glove, and you are having to look through glass in order to pick millimeter sized bacterial colonies, how can you actually see properly and have precision in what you're picking?

The precision is going to be much higher using our colony pickers and it's not going to be so tedious. You can actually track the data from the image exactly where you clicked on the plate. To do all those steps manually would lead to some mistakes. Hudson can build complete microbial cultivation workcells by integrating the colony pickers with growth media dispensers, robotic arms to deliver plates to the different instruments, plate sealers, microplate readers and incubators.

How do robotic arms and moving microplates improve efficiency in the lab?

The lab automation software allows you to track exactly where a specific plate is, within all the instruments. By reading the barcode, you can track that it's gone into an incubator, and the software is going to allow you to track how long that incubation time is, and it will schedule the robotic arm to move the plate immediately to the next instrument at the precise moment that it needs to be moved.

For a human to do that, how are you going to figure out exactly which plate you need and when? Lab automation software allows you to control the environment much more effectively.

Soft Links Player software. Image Credit: Hudson Robotics

You can have up to 15 micro-plate stacks using our robotic arms. That could allow up to 420 micro-plates to be handled in one workcell.

The LabLinx Microplate stacker and tracks can be used to create fast assembly line lab workcells such as coating plates for ELISA protocols. LabLinx can also be used in conjunction with robotic arms to create large complex workcells. The largest workcell Hudson Robotics has designed had 64 instruments in the workcell.

How do Hudson Robotics’ workcells enable complex tasks such as synthetic biology and protein expression?

In synthetic biology, automation varies widely. Almost everything that Hudson does has some flavor of synthetic biology. Plasmid prep, DNA transformation, DNA and RNA normalization, NGS library prep, gene assembly and proteomics are just a few applications Hudson has experience automating. Hudson application specialists work closely with our clients to understand their protocols and through-put requirements to configure workcells to meet their need.

Synthetic biology workstation. Image Credit: Hudson Robotics

How does Hudson Robotics customize robotic instrumentation to suit their customers research and development projects?

Hudson can use ‘off the shelf’ instruments to create unique workcells based on a client's protocols and through-put requirements. This can include integrating instruments from other manufacturers. Then there is the client that says, "Well, your instrument will do 90% of what we need, but there is this 10% where there needs to be customization to meet our requirements.

Hudson is run by engineers. We can customize the instruments, by physically designing and manufacturing custom parts for the instruments or writing software as needed.

About a third of our business is OEM manufacturing where we're manufacturing products for companies to sell under their own brands. We work with companies through the stages of prototyping to getting the final product to market.

They sell them, and depending on what they want us to do, we'll install the instruments at the client’s site or we will train the company’s technical staff to do their own installations.

How can our readers find out more about Hudson Robotics?

To learn more about Hudson Robotics please go to www.hudsonrobotics.com, email [email protected] or call (973) 376-7400.

About Tom Copeland

Tom Copeland is the Sales and Marketing Coordinator at Hudson Robotics specializing in Laboratory Robotics & Laboratory instrument Solutions/Services (Rapid_pH pH meter, microbial cultivation/colony picking solutions, automated pipettors, reagent dispensers, plate washers, magnetic bead & filter plate solutions, robotic arms and more...) Contact information [email protected] (973) 376-7400 ext 209