Sponsored Content by AutomataMar 16 2023

In this interview, we speak to Mostafa ElSayed, CEO of Automata, about their new, open, integrated lab automation platform Automata LINQ and how it unlocks labs' people, space and potential.

Please could you introduce yourself, tell us about what Automata does, and what makes it exciting?

My name is Mostafa ElSayed, and I am the co-founder and CEO of Automata. Automata is a laboratory automation business that was founded as a startup in London in 2015. What we work on is moving laboratories towards a model of open, integrated automation, which allows them to access the full potential of automation many are missing today.

If you walk into a laboratory today, there is a pervasiveness of partial automation. In the trade show today, you will see a lot of these devices that automate a step in a scientist’s workflow.

We have seen a massive demand in the market for automation that takes that partial automation and connects it together to automate that scientist’s complete workflow. We call this kind of automation open, integrated automation and that is what we are focused on here at Automata.

You are the CEO and co-founder of Automata, a lab automation company. Can you tell us a little bit more about it? What are some of your aims and missions?

Automata was born from an observation that automation was not taking off in a range of markets. We have seen the world of automotive manufacturing get transformed through automation. We have a fundamental belief that this technology can change the way people work.

Being in the market for so long, for five years, and selling hundreds of our robots, we realized that customers were starting to use robots more and more, but they were not adopting the technology at a scale that could transform their business.

We decided two years ago that for a company to truly adopt automation at scale, there is a change that needs to happen in the management process. Automata cannot just be involved in a part of that journey. We have to own that journey to deliver value to our customers as quickly as possible. This is the idea of time to science. We have transformed the business around that idea, both in the types of products we make and the teams we create to support our customers on that journey.

It has been a really exciting couple of years. We have started to see our customers and the laboratories that we work with adopt this technology at scale. They are now able to run their laboratories at the throughput that they previously were not able to achieve and at a reliability rate that was previously impossible under manual paradigms. For us, it is a really exciting time in the adoption cycle of this technology.

Laboratory automation has seen tremendous advancements in recent years, with many companies turning to automated procedures to increase their workflow. What could automation bring to the life science space, and which sectors would particularly benefit from this?

We see three main drivers for automation in this sector. The first is like the bread and butter of automation, which is the reduction of menial tasks. Everyone knows that this is the benefit of automation.

In the life sciences, the word science is heavily dependent on the repeatability and reliability of the results. It was shocking to us when visiting laboratories that operate at scale in various institutions that their error rates were through the roof. The traceability of a sample is opaque at best. We have seen automation change other industries in this respect. I think this is a clear benefit that automation can bring to this market.

The last benefit is what we are seeing in spaces like next-generation sequencing, high throughput screening, and experimentation for the reasons of drug discovery. Automation is a fundamental tenant for them to be able to do these workflows at the pace and scale that they need to achieve their target.

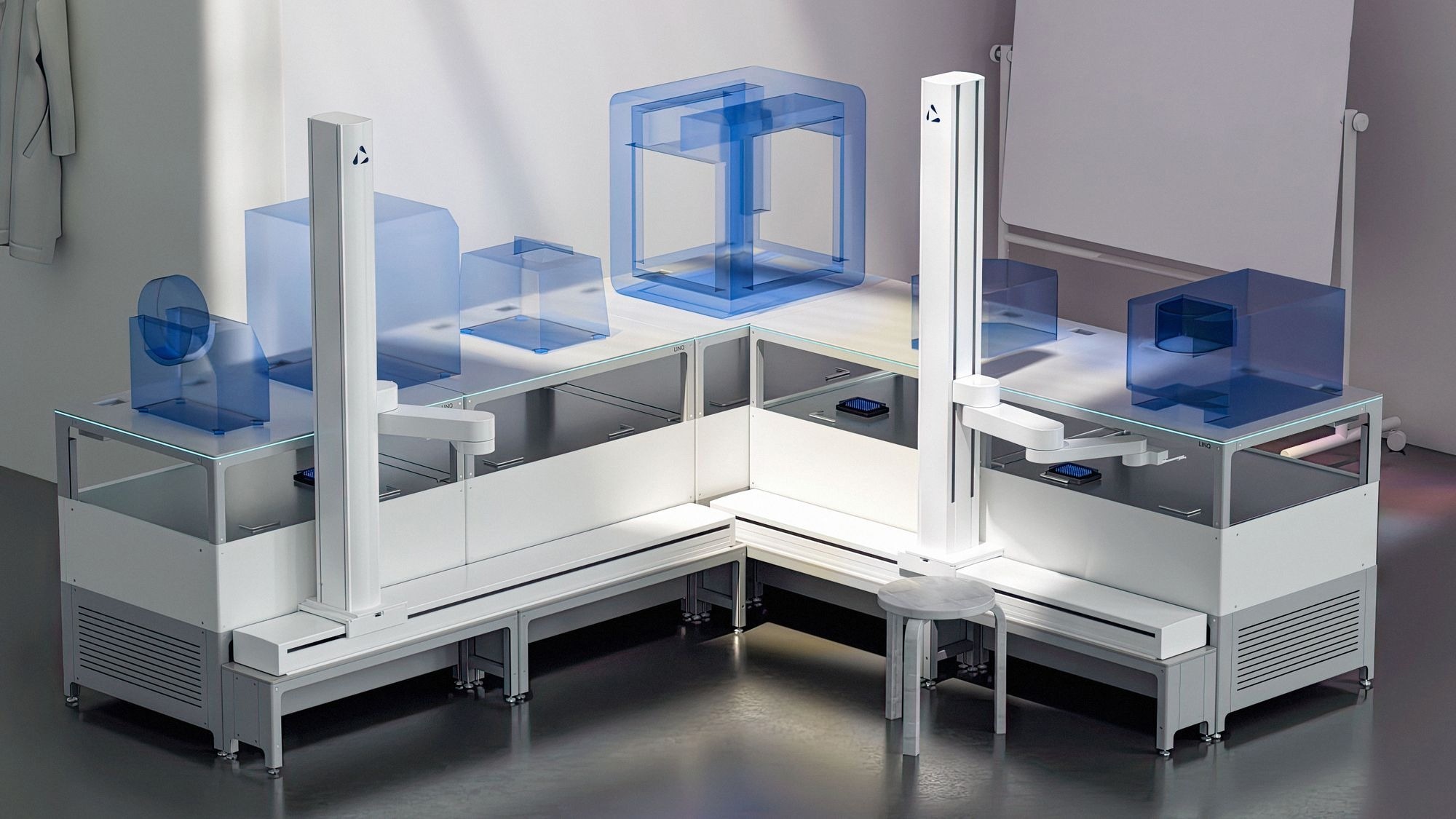

Image Credit: Automata

At Automata you have developed Automata LINQ, a platform that provides true end-to-end automation by both robotically and digitally connecting lab equipment. Can you tell us more about this? What advantages does using LINQ have not only for research but innovation also?

We are big believers in the rise of automation scientists. We have seen this role in some of the most progressive laboratories that we have worked with. There is a newly empowered role in these organizations for an individual who is responsible for the adoption of this technology.

Our job is to empower them through our technology. We do not see ourselves as the experts in their space. We see ourselves as helping those experts. That is why LINQ was born and why it is not just a hardware offering. The LINQ combines our fully automated lab bench, which fits into the same footprint as a regular lab bench while providing robotic connections between instruments, and our software which digitally connects instruemnts and enables true walkaway time. With LINQ, our goal is to empower automation scientists to transform the organizations that they move.

You recently attended SLAS 2023. Can you tell us more about what technology you showcased here?

At SLAS this year, we unveiled the LINQ platform for the very first time. Automata LINQ supports labs at every level of automation, by combining three components: the Automata LINQ bench, the Automata LINQ software and a world-class service, to create a lab automation solution specialised for each lab's workflow and lab.

We were running demos at our stand showing the end-to-end automation of media exchange, cell counting and imaging and quality control in genomics capabilities. These are just a few examples of ways the platform can be utilised in labs. Because of the flexibility of both the size and configuration of the bench (it can be set up like a linear bench, or as an islan, or to fit around corners), and the fact that it can be integrated with any number of 3rd party instruments, it is able to be adapted for any lab or workflow.

At SLAS2023, we had a really good response because I think people are intrigued that these capabilities are possible within this footprint and within a business model that adapts to them.

The COVID-19 pandemic put a hold on many in-person exhibitions and conferences. Why are in-person conferences and exhibitions so important for companies like yourself? What advantages do they have compared to virtual ones?

For in-person events, especially in this kind of market, there is a ‘show me’ attitude. Nothing speaks louder to these automation scientists than for them to see a like-for-like in person. It is one thing to educate them about what automation can do. It is another thing to show them.

Again, you should not burden these people with the idea of what can I do with this technology? It is our job to show them what is possible and then build products that allow them to scale from there. I think in-person events are a fantastic vehicle to do that.

The ongoing COVID-19 pandemic has also highlighted the need for fast, automated technologies concerning testing capabilities. What involvement did Automata have within the COVID-19 pandemic?

COVID-19 was an opportunity for us to demonstrate two of the company’s fundamental principles that make up our values. The first is space. This is 50% of the reason why Automata got a significant number of projects during the COVID-19 pandemic. We were able to speak to the urgency of our customers and show an ability to respond. We embed people in your laboratories if you have the scale that makes it necessary. The other factor that COVID-19 showed is what can happen when you automate in terms of turnaround time and scale. Another reason we have seen success during COVID is that the science was being figured out as we went along. In the world of traditional automation, that is a very troublesome paradigm.

If you talk to some of our customers, you will see that one of the main reasons they chose us is because we work on 48-hour turnaround times by adapting our platform to fit the customers’ needs. Furthermore, we are now in a place where they can do it themselves through our product.

These tools should never get in the way. That is something we see heavily in this market. The tool can be fundamentally great, but many times the elements associated with that tool can become cumbersome for these scientists.

Fully automated media exchange and supernatant sampling

Are you hopeful that with increased awareness surrounding the advantages of companies automating their workflow, we will see more researchers using these kinds of platforms?

We are seeing a level of interest, demand, and awareness that we could not have imagined prior to the pandemic. We set up an advisory board and what they are seeing on the ground is incredible.

What we are also seeing in genomics, for example, is the universality of these technology platforms, which is really exciting. It shows that genetic platforms are applicable to a wide variety of diagnostic uses. In the past, this universality was somewhat crippling.

With this kind of technology, which we have seen in the NHS, is that you can take these platforms and build a genomics or genetics factor. This is where you house technology under one roof that services a variety of diagnostic verticals. To me, if that is not the future, I do not know what is.

What advice would you give to researchers or companies looking to start using automation but are unsure where to start?

First and foremost, it is easier than you think. Look for people who make it easy for you. Do not look for those who have opaqueness and credibility combined. The second is that we find success the fastest, this idea of time to science, for customers who understand that they are the experts in their assays. The customers are the experts of their workflows, and we help them automate them.

As technology providers, we want to make these tools work for you. I think it is that synergy between not preaching about customers’ workflows or scientific processes and respecting that they are the subject matter expert in their field.

We also see a significant ‘land and expand’ mentality in this market. A lot of these people are now comfortable with the idea of liquid handling, for example. It is a very small step to question what can be automated in a liquid handling operation. This ultimately drives the seed of change. Then three months or so down the line, companies could have automated more than 43% of their overall process.

We have seen this in people who have adopted automation for the first time. Initially, they did not even have automated liquid handling. We have been in laboratories where automation is their bread and butter, and they are known for the scale of automation they have. Automating a process step-by-step is a really important part of the journey for organizations to adopt this kind of technology.

What do you believe the future of laboratory automation and robotics will look like within the life sciences industry?

We strongly believe in and support the rise of automation. We believe that this will transform the industry. There will be an increasing number of laboratories with completely automated workflows in the future. This enables incredibly fast turnaround times and incredibly fast-changing times. Ultimately, the benefits are the flexibility and the scale of experimentation.

We are also seeing, in the UK, for example, the idea of empowering people who previously could not access automation because they did not have the scale to financially argue for automation.

Once you build this idea of a factory and a horizontal technology platform that services a variety of people within the same organization, whether that is the NHS, a private diagnostic provider, a biotech research agency, or a CRO, you suddenly have an ability to decide who can access automation in those organizations. This barrier massively comes down. To use a common word, the democratization of who can access this technology rises.

Finally, we are seeing some of the most progressive organizations promote ideas like completely light-out wet laboratories, which for people like us is incredibly exciting. You can see the benefits quite clearly. It all relates to scale, flexibility and reliability while empowering an organization’s scientists and operators to do more meaningful work.

Image Credit: PopTika/Shutterstock.com

What is next for Automata?

At Automata, we feel like we’re just getting started. In the last two years, people have started to understand what we are trying to do, and they are adopting our attitude at scale. We have moved them across that automation journey, and they are starting to see the benefits of this technology and scale.

For us, that means launching the LINQ globally this year. It means geographic expansion into these exciting markets that we see in the US from our home base of the UK and Western Europe. It means doubling down on the use cases that we see today that are incredibly exciting. There are a variety of use cases, for example, spaces like cell culture and next-generation sequencing.

Due to the company’s growth in the last two years, last year we closed a $50 million fundraiser to allow us to support that expansion. We are hiring across the team from a commercial perspective, a product perspective, and an engineering perspective.

We are looking to deepen our partnerships with companies that we have been working with over the last two years, even perhaps bringing a few companies into the umbrella of Automata. I think there is room for a couple of European companies to rise in this space. I think the east and west coast have this incredible ability to build these incredible change-making organizations. We see many companies doing amazing things in the UK, but they do not have access to that scale. If they could have access to it through Automata, that would be an incredibly exciting thing.

About Mostafa ElSayed

Mostafa ElSayed is the CEO and co-founder of Automata, a world-class, London-based automation company disrupting the life sciences industry by creating and deploying fully automated solutions into labs across the world. Its current workflow automation offering, LINQ enables labs to unlock their people, space and potential by offering true walkaway time, increasing throughput and improving the quality of results.

Prior to co-founding Automata, Mostafa spent five years at Zaha Hadid Architects, becoming the Lead Designer of the firm’s Computation and Design Group. Automata was born from Mostafa’s fascination with the potentials of design, engineering, and robotics to transform workplace efficiencies and output.

Automata is today a leader in open, integrated automation in life sciences, where Mostafa spearheads the company’s vision and innovation with one eye to the future of life science automation. Automata is changing perceptions that automation technology is expensive and complex and redefining what it means to ‘work’, empowering industries to automate previously dangerous, boring, and difficult physical work.

About Automata Technologies

Automata is a leading robotics and automation company powering the laboratories of the future. Our mission is to unlock labs' space, people, and potential through automation hardware and software.

Our lab automation technology is efficient, scalable and reliable and effectively carries out routine tasks, to free up scientists to work on innovative research.

We meet labs where they are on their automation journey, and are the trusted partner to customers including trusts within the NHS, bit.bio and The Francis Crick Institute. We are also supporting advancements across Core Testing Labs, Academic Institutes, CDMOs, Pharma’s and Biotech’s.

We meet labs where they are on their automation journey, and are the trusted partner to customers including trusts within the NHS, bit.bio and The Francis Crick Institute. We are also supporting advancements across Core Testing Labs, Academic Institutes, CDMOs, Pharma’s and Biotech’s.