Introduction

In UVC LEDs, the term “spectral quality” has different implications based on the application. For instance, a narrow peak without secondary peaks is usually favored in spectroscopy, while the total energy within the UVC peak can be utilized to neutralize microorganisms for disinfection purposes.

Spectral Quality in Spectroscopy

Deep UV LEDs are an alternative light source to conventional full spectrum UV light sources. In fact, applications in fluorescence and absorption spectroscopy are now implementing deep UV LEDs. These LEDs have simple spectra, i.e., a single peak having a narrow spectral bandwidth, unlike the wide and complex spectra seen in UV lamps.

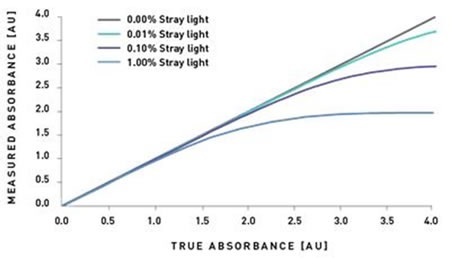

Traditional deep UV LEDs were characterized by small secondary peaks. In spectroscopy, when stray light from a broad or a secondary peak reaches the detector, it can obstruct the measurement result. As illustrated in Figure 1, the presence of stray light not only leads to reduced concentration measurement, but also results in poor linearity of measurement, thus giving a false picture of the actual condition.

Figure 1. Linearity of measurement versus stray light.

In fluorescence spectroscopy, secondary peaks emitted from a light source can impede understanding of the emission spectra, since there is always the possibility of reduced signal-to-blank ratios and overlapping wavelength. This effect is more significant when the quantum yield of fluorescence is low.

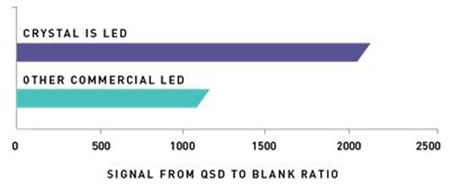

Crystal IS follows streamlined manufacturing practices, which reduce the presence of secondary peaks and thus result in better signal-to-blank ratios and superior linearity of measurement in fluorescence, as shown in Figure 2.

Figure 2. Comparison of fluorescence sensitivity using QSD (Quinine Sulfate Dihydrate, a fluorescence reference standard).

Crystal IS’ UVC LEDs have a narrow primary peak with little or no secondary peaks and help improve sensitivity and measurement precision. Furthermore, this excellent spectral quality not only allows for simple optical designs, but also reduces the cost of them.

Spectral Quality for Disinfection

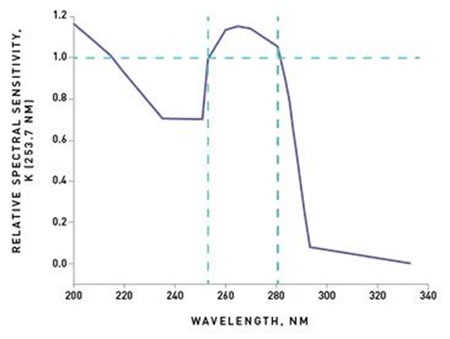

Germicidal ultraviolet light is often employed to deactivate pathogens such as viruses and bacteria. The nucleic acid that absorbs UV-C light from 250 to 280nm range undergoes a photochemical transformation, which in turn deactivates the pathogens. The action spectrum of B. Subtilis shown in Figure 3 is often used as a baseline for germicidal effectiveness in water disinfection. Germicidal power output is measured with the LED’s output power as a virtue of wavelength with the absorption spectrum.

Figure 3. The action spectrum according to Sommer R, 2004. Although the 260-270nm range is regarded as the most favorable germicidal wavelength, Figure 3 reveals that absorption of UVC energy transpires across the 250 to 290nm range, which may play a role in disinfection, although at different levels. This happens to be the most important spectral parameter in these kinds of applications.

The optimization process of the germicidal power or germicidal action (Po) depends on the overlap of the microbe’s absorption spectrum and the diode’s emission spectrum, which may reveal some amount of difference based on the species to be deactivated. Therefore, in germicidal action, the quality of spectra is of utmost importance when maximizing the overlap of absorption and emission.

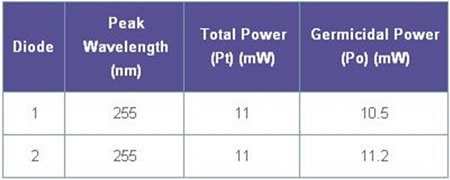

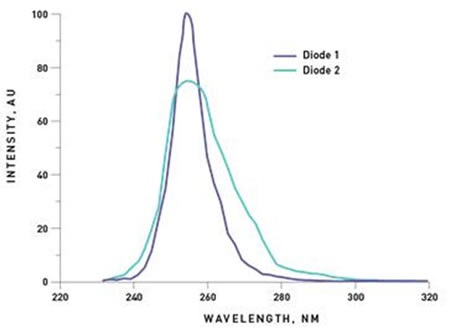

In order to demonstrate this phenomenon, two diodes having the same total integrated power (Pt) and peak wavelength are compared, as shown in the table below. While the diodes would possess the same Pt, some variation will be present in the optical power available for germicidal power (Po).

Table 1. Diodes with same peak wavelength and total integrated power (Pt)

In disinfection processes, the shape of the curve is not important, provided the curve falls between the 250 and 280nm wavelength. In Figure 4, the spectral curves of the two diodes show that the FWHM of Diode 1 is extremely narrow compared to that of Diode 2. On the other hand, the germicidal power for Diode 2 is comparatively higher than Diode 1. This is because more of the emission from Diode 2 falls inside the germicidal range.

Figure 4. Spectra of two example diodes. Note the difference in the FWHM.

Conclusion

The quality of spectra is a major aspect for applications where UVC LEDs are typically used. However, disinfection and spectroscopy applications place different demands on the LEDs’ spectral quality. Therefore, in disinfection applications, high integrated intensity across the entire range of germicidal wavelengths is required, while in spectroscopic applications high intensity at one wavelength of choice is preferred.

About Crystal IS

Crystal IS, an Asahi Kasei company, is a U.S.-based manufacturer of high-performance LEDs that emit UV light. These LEDs are integrated into our customers’ products to sterilize and disinfect water, air and surfaces in a variety of applications. Additionally, our LEDs can be used as light sources for scientific and industrial instrumentation applications.

Crystal IS, an Asahi Kasei company, is a U.S.-based manufacturer of high-performance LEDs that emit UV light. These LEDs are integrated into our customers’ products to sterilize and disinfect water, air and surfaces in a variety of applications. Additionally, our LEDs can be used as light sources for scientific and industrial instrumentation applications.

Crystal IS was founded in 1997 by Rensselaer Polytechnic Institute (RPI) professors, Leo Schowalter and Glen Slack to develop native aluminum nitride (AlN) substrate technology for more powerful and reliable semiconductor devices.

Today, our award-winning technology provides the industry’s highest performing ultraviolet (UVC) LEDs.

As the leading developers of the most effective UVC LEDs in the industry, our breakthrough performance is made possible by our low-defect density, single crystal aluminum nitride (AIN) substrates and our proprietary-technology for crystal growth.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.