Introduction

Gluten, a protein composite found in wheat and related grains such as barley and rye, gives a chewy and elastic texture to dough. Gluten causes health problems in people suffering from celiac disease or gluten intolerance. In these individuals, even a small amount of gluten can cause bowel dysfunction, abdominal pain, debilitating bloating and fatigue, as well as many non-abdominal symptoms.

However, it is very difficult to maintain a gluten-free diet since many processed foods such as luncheon meats and soy sauce contain wheat derivatives. With a growing number of gluten-free products becoming available, the need for precise and cost-effective assessment of the grains used to make such products has significantly increased.

Gluten-free Grains

Amaranth and buckwheat are gluten-free grains that are often processed on machinery that is also used to process other grains. Furthermore, when different types of grains are grown alongside each other in the field, there is also a possibility of contamination.

While contamination is generally less than 2%, the rigorous requirements that define “gluten-free” call for regular sampling during the processing of grains.

Figure 1. Many grains look very similar, and can be difficult to distinguish by eye.

During the sampling procedure, trained workers have to manually inspect each sample of 50,000 kernels, making it a tedious and time-consuming process. Even then, repeatability is considerably low owing to slight shape and color variations among certain kernels (Figure 1).

NIR Spectroscopy and Machine Vision

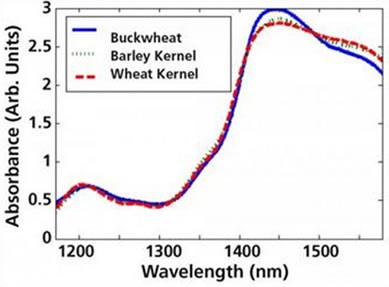

When machine vision is integrated with the near-infrared spectra of each kernel, the accuracy of classification is increased to more than 99.5%. Since each grain variety has a unique protein content, variations in absorbance spectra emerge at 1450 and 1550nm and these can be entered into predictive analytics algorithms so that a sorting decision can be made.

Figure 2. The NIR spectra of buckwheat, barley, and wheat grains differ above 1400nm, enabling spectroscopic identification.

The QSorter Explorer is an advanced system integrated with an Ocean Optics’ NIR spectrometer along with a tungsten halogen lamp. This system captures the reflection spectra of all the kernels as they pass through the eye of a high-speed robot, which can sort 30 kernels per second (Figure 2).

Rapid Grain Inspection

Within 30 minutes, about 95% of the kernels can be classed as gluten-free, while the remaining grains are directed to another bin to be visually examined. This bin is smaller and includes a combination of false positives and undesirable grains, such as buckwheat kernels that failed to fulfill the confidence factor required for decisive sorting.

Although some amount of manual examination is still needed, the entire process can be carried out in 1/20th the time. This not only significantly improves the efficiency of the process, but also acts as a check point for faulty processing equipment. In addition, the repeatability error is also reduced to 2%, which is 10 times better than the estimated human error.

Conclusion

The combination of machine vision and NIR spectroscopy gives rise to faster and more precise sorting of grains for contamination with gluten. This makes it possible to perform reliable and more frequent quality assurance for grains intended for gluten-free products.

About Ocean Optics

Ocean Optics is a diversified photonics technology firm and a global leader in optical sensing. With full-service locations in the United States, Europe and Asia, we serve a wide range of markets, including process control, consumer electronics and medical diagnostics.

Ocean Optics is a diversified photonics technology firm and a global leader in optical sensing. With full-service locations in the United States, Europe and Asia, we serve a wide range of markets, including process control, consumer electronics and medical diagnostics.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.