XPS is playing an important role in the development of the coating of surgical meshes. This has proven to be a major challenge for plasma technologists.

The well-established method for the chemical characterization of material surfaces is known as XPS. In recent years, key developments such as imaging, have resulted in a wider range of applications. Both manufacturers and suppliers of commercial and technical textiles are now exploiting XPS as an ideal tool to develop and optimize the types of surface coating or treatment demanded by industry and consumers.

Plasma Treatment of Medical Textiles

Plasma treatment of medical textiles Polymer meshes, including polypropylene and polyester, are typically used for the surgical repair of hernias and other soft tissue defects. Although the use of mesh material has led to improvement in this kind of surgery, their implantation has been known to be associated with serious infection rates. To reduce the infection rates of such meshes, their surface properties must be improved. The application of low pressure and atmospheric pressure plasmas for the functionalization and coating of textile surfaces is becoming increasingly important. The key areas of plasma process activity for new textile products include the production of repellent surfaces to limit the adhesion of biofilms/bacteria. An example of this is for use in surgical and hygiene applications. XPS is useful for investigating the integrity of a PEG (polyethylene glycol) plasma coating on a PP (polypropylene) mesh.

XPS of PEG Coated PP Mesh

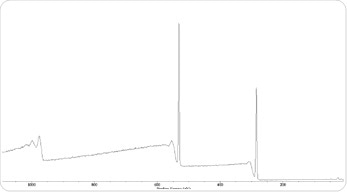

XPS of PEG-Coated PP Mesh the PEG coating can be detected by XPS spectroscopy in a survey spectrum as the presence of oxygen, however, only carbon is detected from an untreated PP surface.

Figure 1. XPS survey spectrum from PEG-coated PP.

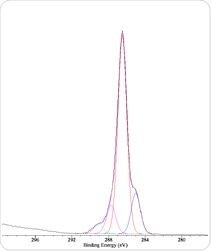

Figure 2a. C 1s XPS spectrum from PP mesh with good PEG coverage.

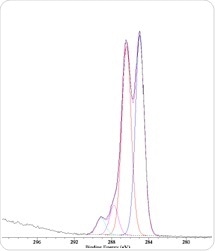

Figure 2b. C 1s XPS spectrum from PP mesh with poor PEG coverage.

Examination of the chemical states present are shown using high-resolution C 1s spectra. They also indicate the extent of the surface treatment. The C-O rich PEG coating dominates for meshes with good PEG coverage. From these experiments, it can be seen that large C-O component at a binding energy of 286.5 eV. On the other hand, this is in contrast with the significantly higher C-C component, characteristic of the PP mesh, for lower coating coverages.

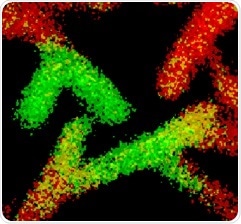

Figure 3. Overlay of C-C and C-OI chemical state images from a PEG-based coating on a PP mesh. Green regions

= good coating coverage (C-O), red regions

= poor coating coverage (C-C). Image dimensions

= 0.8 x 0.8 mm.

XPS imaging is important for assessing coating coverage in conjunction with the spectroscopy. For a region of plasma-treated mesh, the PEG-based coating is incomplete, and therefore PP mesh can be detected.

Furthermore, the PEG coating and integrity can be quantified as a function of the plasma treatment parameters. Therefore, XPS can aid in the optimization of the PEG coating for maximum anti-adhesive properties. This technique can be further used to assess the effects of sterilization such as autoclaving, gamma irradiation, ethylene-oxide, or packaging/storage on the PEG coating.

About Kratos Analytical, Ltd.

For the last 46 years Kratos Analytical has provided state-of-the-art spectrometers for surface analysis and we are committed to continuing with development of leading technologies. As we approach our fifth decade Kratos Analytical is still dedicated to providing service, quality and customer satisfaction, and we believe that this specialist web area will help you find the information you need for your surface analytical applications.

For the last 46 years Kratos Analytical has provided state-of-the-art spectrometers for surface analysis and we are committed to continuing with development of leading technologies. As we approach our fifth decade Kratos Analytical is still dedicated to providing service, quality and customer satisfaction, and we believe that this specialist web area will help you find the information you need for your surface analytical applications.

Global Headquarters

Kratos Analytical has its headquaters in Manchester, UK and offices in the USA, Germany and Japan. We have a large network of agents and representatives throughout the world.

The Kratos Analytical Ltd is based in Manchester, UK, and prides itself on being highly innovative, responsive, and internationally focused. Its strengths lie in the quality of design, in the excellence of its products and in the commitment to partnerships with customers. This market-leading technology is backed by the skills and experience of a responsive, forward-looking workforce.

Shimadzu Corporation

Kratos Analytical Limited is a wholly owned subsidiary of the Shimadzu Corporation of Kyoto, Japan. Shimadzu Corporation is a multi-billion dollar supplier of a wide range of scientific and industrial products to world markets.

Globally the Shimadzu corporation employs 7000 staff, it has a growing number of manufacturing facilities world wide including USA, The People’s Republic of China, Australia, the Philippines and the UK with sales and distribution outlets in almost all countries in the world.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.