Lactose is a white, crystalline powder with a slightly sweet taste. It is a disaccharide which is made up of glucose and galactose. It is generally used as an excipient (a binder or filler) within the pharmaceutical industry.

To manufacture lactose powders, the shape, size and size distribution of particles must be modified, with these particles possessing distinct characteristics in terms of compactability, granulability and flow behavior.

Lactose is frequently referred to as ‘milk sugar’ because it is a naturally occurring carbohydrate constituent of milk. Whey is needed to make lactose, and this is often acquired as a by-product of cheese manufacturing. Lactose can be crystallized by concentrating the whey, and following crystallization the lactose will be filtered, washed and then dried.

A range of raw purities and contents may be manufactured, depending on the lactose’s intended use. Pharmaceutical grade lactose, for example, will contain more than 99.5 % lactose monohydrate and will possess a level of purity appropriate to its application.

Pharmaceutical grade lactose can need a range of particle size distributions and appropriate modifications during the formulation of dry powders for inhalation or oral solid dosage forms. Characteristics such as flow, compressibility and granulability of the lactose powder will be dependent on the size, shape and size distribution of the particles present.

The physical attributes of these particles can be altered if needed using techniques like sieving, milling, spray-drying or agglomeration. This is done to guarantee that the lactose possesses the most ideal functional characteristics for either blending, granulation or tableting.

To make sure that the lactose is of high enough quality, it is important to be able to undertake quick, accurate particle size analysis.

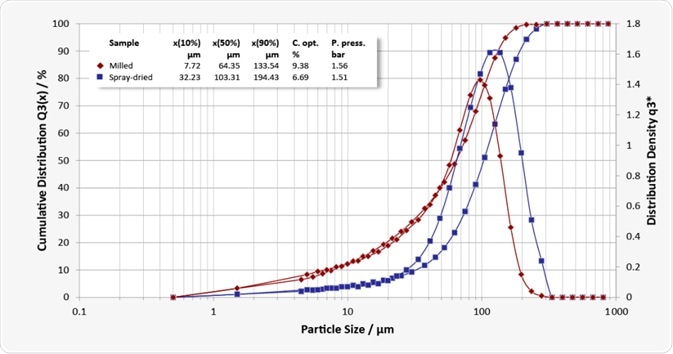

Particle Size Distributions of Different Lactose Qualities

Particle size distributions of milled lactose (red curve: evident fine fraction) and spray-dried lactose (blue curve: narrow distribution)

Better Particles with the Best Instruments

Laser diffraction systems such as the ones offered by Sympatec can provide reliable, accurate and efficient monitoring of the particle size distribution of practically any lactose powder product. These devices are ideal for quality control processes within a laboratory environment, or even in the process itself during high-volume production.

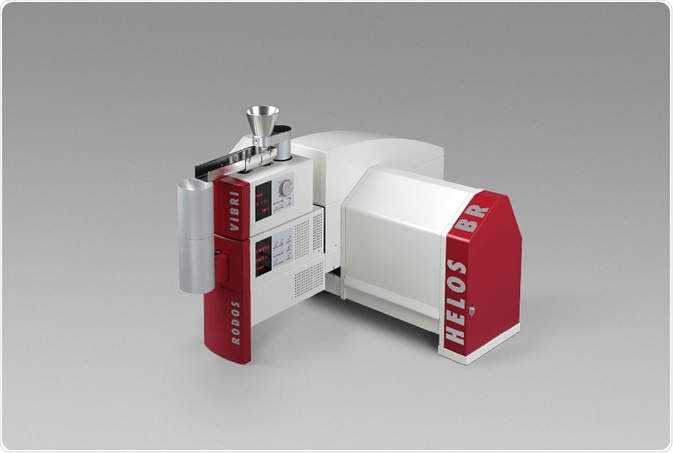

The HELOS sensor, used in combination with the RODOS dry dispersion technology offers a reliable solution within both these environments. It allows for reproducible dispersion of larger sample qualities, therefore ensuring that the measurement results it obtains are statistically reliable.

HELOS/BR with RODOS/L and VIBRI/L

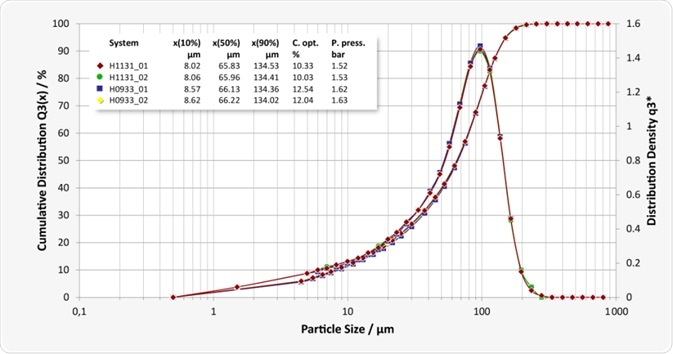

A robust, dry method such as this one can deliver excellent comparability and repeatability of measurement results, even between systems or across production facilities at various locations. Not only that, but measurement methods developed for specific product qualities can be easily transferred to other systems as standard operating procedures (SOP).

This impressive range of features allows for consistently high quality and also consistency between different batches of product, which in turn justifies consumer and business confidence in the quality of the products being manufactured.

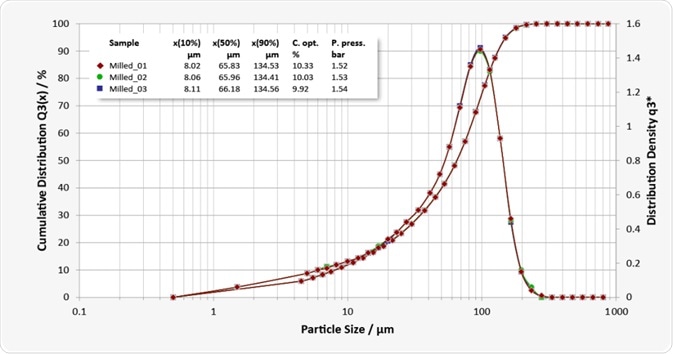

Repeatability and System-To-System Comparability

Three repeat measurements of subsamples of a milled lactose with good repeatability

Good system-to-system comparability of a lactose batch measured on two different systems

Fast and Reliable In-Process Quality Control

Laser diffraction systems within the MYTOS family offer in-process control, for example during batch-based or continuous micronization of dry powders. When working alongside innovative and representative samples, these can be implemented in either on-line or in-line systems that not only meet GMP requirements but can also be adapted for use within explosion-hazard areas (ATEX).

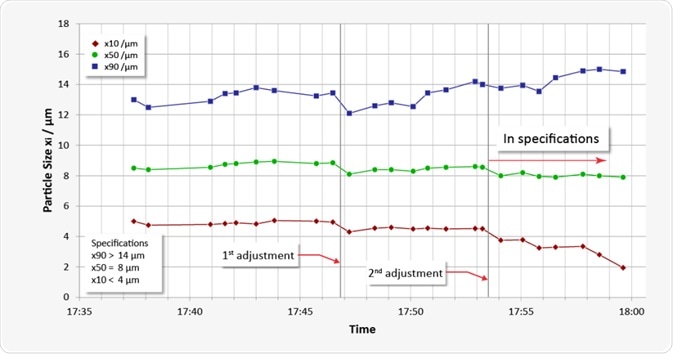

Trend display of critical values (x10, x50, x90) with real-time adaptation of air jet milling in order to satisfy the required specification

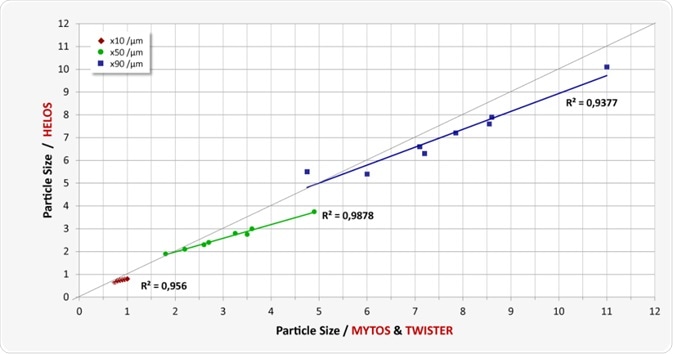

Comparability of MYTOS & TWISTER on-line measurements with HELOS & RODOS particle size analyses in the lab (n=8 different lactose samples)

Using the same components and technologies within both the laboratory and manufacturing settings ensures that results have maximum comparability when scaling up batch sizes.

About Sympatec GmbH

Sympatec develops, manufactures, sells, services and supports an innovative range of best instruments for particle size and particle shape analysis in laboratory and process: from small quantities as part of active ingredient development and preformulation through to manufacture of active pharmaceutical ingredients in batch operation or continuous volume processing on an industrial scale.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.