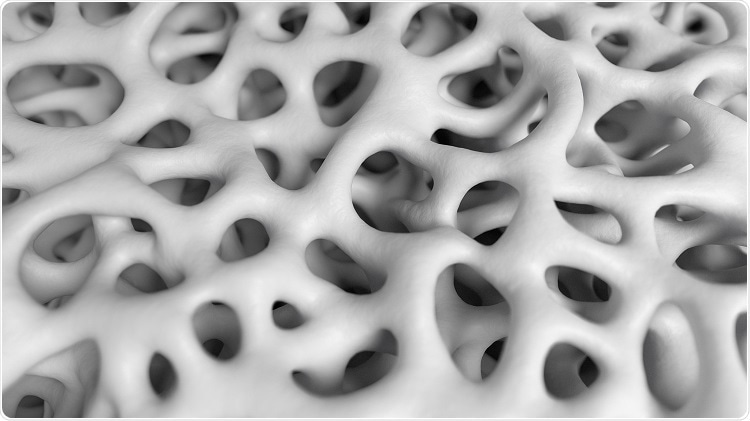

In 2012, researchers from the Division of Nanotechnology and Functional Materials of Uppsala University in Sweden were the first to synthesize a mesoporous magnesium carbonate (MMC) that had been impossible to create, until then.

They named the material Upsalite® after the city Uppsala. Upsalite/MMC has the highest surface area of any substance in its class, and as a moisture adsorbing material it performs equal to metal-organic frameworks, zeolites, and carbon nanotubes, but it can also adsorb moisture at low humidities better than existing zeolites on the market.

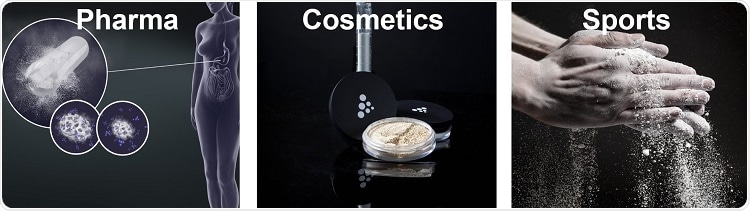

With the aim to commercialize the material, the research team went on to found Disruptive Materials. AZoMaterials spoke to Disruptive Materials about the inception of the company and the scope for applications in the sports, pharmaceutical, and cosmetics industries.

How was Disruptive Materials founded, and how was MMC/Upsalite created?

In 2012, when the team led by Professor Maria Strømmeat Uppsala University first succeeded in synthesizing MMC, the purpose was to create a safe, porous material that could be utilized to stabilize poorly soluble drugs in their amorphous form.

A number of active pharmaceutical ingredients (API) exhibit poor water solubility, which is a huge challenge in the pharmaceutical industry: around 70 percent of the pipeline drugs are poorly soluble. One way to enhance water solubility is to load an API into a mesoporous structure and thereby stabilize it in an amorphous highly soluble form. This method has been successfully demonstrated for a number of mesoporous silica-based drug delivery systems.

At the time, the MMC system was absent from the scene and numerous scientists had unsuccessfully attempted to create such material. It was therefore a major achievement when the team finally made a successful synthesis.

The team decided to file a patent application and it received massive media attention when the manuscript and press release were published in the summer of 2013. They also received many material requests from researchers and industries from around the world.

Image Credit: Disruptive Materials

It was thus clear that the MMC material could have large market potential and Disruptive Materials was formed by the inventors immediately afterward in September 2013. Today, Disruptive Materials has 30 employees and approximately half of the team is working with research and development.

We are well financed and have undergone three financing rounds; the last one was recently completed and will bring in another 10 million euros to the company. Although AZoMaterials first reported that MMC would be employed in clean technology, we have instead focused on the three business areas of cosmetics, sports, and pharma.

The scientist at Uppsala University had already considered pharmaceutical application of MMC, but sport and cosmetics are two new interesting areas which have great commercial potential in the short term.

Image Credit: Disruptive Materials

Following the successful synthesis of MMC, were there any challenges associated with the scaling up of manufacturing this material? If so, how have these been overcome?

Although initially, it was challenging to find a way to synthesize the material, it was a relatively simple and scalable process. The biggest challenge was to locate a contract manufacturer with access to the required equipment, who could help us scale up our process instead of building our own factory.

We now use two contract manufacturers who are both based in Germany and are ISO certified. We have recently received REACH registration allowing us to produce up to 10 tons per year. The manufacturing is going well, the process is constantly being optimized.

Image Credit: Disruptive Materials

MMC has the highest surface area of any material in its class. How has it been used in an optimized drug delivery platform for the pharmaceutical industry?

If a drug has low solubility it will not be efficiently taken up by the body if taken orally. Instead, it will just go straight through the gastrointestinal tract. A way to solve this issue is to make amorphous forms of the drug, but this presents a challenge in that amorphous formulations are less stable.

One way of overcoming this challenge is to dissolve an active pharmaceutical ingredient (API) in an organic solvent and loading it into a porous material with pores so tiny that each pore fits approximately one molecule, which hinders any re-crystallization. In spite of the lack of crystallization, this still creates a solid dispersion, which is physically stable over time. The bigger the surface area and pore volume of the material, the more API can be loaded into the material.

A proprietary drug delivery platform based on the MMC material platform has been developed, which we have named Pharma-MMC (pharmaceutical grade mesoporous magnesium carbonate). Pharma-MMC has exceptionally good drug loading capacity and is optimized for industrial processing. Multiple potential drug product candidates in development and patent applications are currently on file.

Stabilize poorly soluble drugs with Pharma-MMC

Video Credit: Disruptive Materials

MMC also has excellent moisture adsorption capacity and oil absorption properties. How has it been developed for additional sports and cosmetics applications?

Upsalite is the commercial brand name for MMC in sports or cosmetics products. The first sports product on the market uses the excellent moisture adsorption properties of Upsalite. It is a climbing chalk, which has been developed together with Black Diamond, a successful global climbing company.

Chalk, in the form of hydromagnesite (crystalline magnesium carbonate) has a flaky crystalline structure that creates friction and can take up some moisture but Upsalite has a moisture adsorption capacity that is 10 times better than hydromagnesite. When added to regular chalk Upsalite helps to absorb excess sweat in the hands and gives the climber a better grip, thereby improving the function of the chalk.

A liquid chalk is currently being developed. It can be used for climbing, Cross Fit, weightlifting, or other types of sports where a good grip is needed.

Image Credit: Disruptive Materials

The first products developed together with brands for cosmetics use the excellent oil-absorbing properties of Upsalite. When Upsalite is added to makeup it helps remove excess sebum on the skin and reduces the shine which makes the skin appear oily, greasy or sweaty.

It also has good setting properties, so will help makeup stay in place longer without the need to re-apply. The first product launched in Europe with Upsalite is called PROWDER from Palina Skin Philosophy. It is a Swedish brand that is only sold in Sweden. We are currently also working with brands that are sold on a global market.

Image Credit: Disruptive Materials

If anyone is interested in having Upsalite or Pharma-MMC in their research, development or final products, what is the process to have access to the material?

Disruptive Materials is an innovation and development partner to brands helping them to differentiate their portfolio and product concepts.

For sports and cosmetic applications with Upsalite, products are developed together with brands who then sell the finished products to their distribution networks or directly to consumers. In Pharma, our own drug products are being developed using Pharma-MMC, and thus we are not currently working with any other customers.

The best way to get Upsalite is to contact us to discuss a potential collaboration where both parties would enter into a legal agreement prior to any development or transfer of material. Pharmaceutical grade MMC is currently not offered in the public domain.

What is next for disruptive materials, Upsalite and Pharma-MMC, from drug delivery systems to ready-to-sell sports products and mineral cosmetics?

The goal of the pharmaceutical team is to develop selective drug products or drug intermediates within a market niche. This is something that we hope to see after the first clinical trials, which are likely to be starting in the near future.

A liquid chalk has been developed for sports, and it will be available on the market in 2020. It has been tested with professional athletes and are confident that it performs extremely well. We are working with brands who will place it on the market soon. We are also looking into new applications in sports, where moisture uptake is important.

With cosmetics, the business will be scaled up and the porous mineral makeup will be expanded to make it accessible to global brands. Liquid formulations are also being worked on in-house.

A long-term project is to utilize the drug delivery technique, which is used for pharmaceutical applications, in cosmetics and skincare - that is loading the porous structure with active ingredients. There is also the potential to work outside the three key application areas of pharmaceuticals, sports and cosmetics in the future, but this is not a focus at this time.

About Dr Cecilia Anneren

R&D Director at Disruptive Materials

Dr Cecilia Annerén is leading the R&D team at Disruptive Materials; a fast-growing company developing products and solutions based on Upsalite®, a patented mesoporous magnesium carbonate. She has an extensive scientific background in stem cell and molecular biology from the US and Sweden as well as comprehensive insight from senior positions in R&D, product management and marketing at GE Healthcare.

About Disruptive Materials

Disruptive Materials is a spin-out from the Ångström Laboratory at Uppsala University. We specialize in new advanced materials with extraordinary properties paired with great market potential. The initial focus is on commercializing the world record material Upsalite(R).

Disruptive Materials is all about disruptive innovations within the field of advanced functional materials. We actively scout and seek interesting technology with the potential of becoming true game changers in the industry, we nurture and industrialize these golden eggs and form a tailored go-to-market strategy for each idea, e.g. licensing, in-house manufacturing, partnering, etc.

Disruptive Materials is a dynamic company founded on a unique and patented technology for the production of a groundbreaking mesoporous magnesium carbonate.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.