Sponsored Content by OXGENEJun 1 2020

The relatively short history of gene replacement therapies is a story of the scientific enterprise, perseverance in the face of adversity, and revolutionary discoveries. It includes breakthroughs in cell biology, molecular biology, structural biology, biochemistry, immunology, oncology, virology, engineering, and biotechnology.

However, despite its hypothetical simplicity - overruling the disease-causing effect of an absent or damaged gene by inserting a properly functioning copy - there are still hardly any gene replacement therapies on the market, even though it has been thirty years since Rosenberg et al. proved the potential of retroviral based gene transduction in humans (Rosenberg et al. N Engl J Med 1990; 323:570–8).

Boom: The roaring nineties

The early 1990s were simpler times for gene therapies. Both researchers and clinicians believed that they possessed the key to treating all genetic diseases. Start-ups, spinouts, academics, and investors rushed to engage in this encouraging new market, prompted by the opportunity to develop innovative treatments for gene-based disorders.

During this time, the majority of gene therapy trials employed adenoviruses to deliver the transgene into patients, a technique which was made possible by Professor Frank Graham in the 1970s, via his efforts to understand why some viruses are oncogenic, while others are not.

In 1973, Graham – who, at the time, was a postdoc at the University of Leiden in the Netherlands – was able to create an adenovirus-transformed immortal human cell line, the Human Embryonic Kidney (HEK)293 (Graham et al. J. Gen. Virol. 1977; 36 (1): 59–74).

HEK293 cells can be easily transfected and include the adenoviral E1 genes, which enable replication-incompetent adenoviruses to continue to grow within these cells. These characteristics make them a clear choice for the production of the substantial quantities of a viral vector that are needed for human gene therapy.

While gene therapy was rapidly developing, the human genome project was underway, marking another extraordinary feat of scientific investigation. 2003 saw the first publication of the complete human genome sequence – the result of fifteen years of global research collaboration.

Following this landmark publication, scientists not only had access to the sequence of every human gene, but there were also now maps which detailed the location of these genes within chromosomes, as well as linkage maps which allowed them to track the inheritance of genetic disease (Science. Apr. 11, 2003 and Nature Apr. 24 2003, full issues).

Success, stall, repeat (2003-2017)

With the sheer amounts of information now available, it comes as no surprise that the gene therapy industry continued its work to revolutionize modern medicine. In 2003, the China State Food and Drug Administration was the first health authority in the world to specifically approve a gene therapy - an adenoviral vector called Gendicine, which carried the P53 tumor suppressor gene. However, it was not until 2017 that the U.S. Food and Drug Administration (FDA) approved its first gene therapy - Luxterna for retinal dystrophy - for use in the United States (source: genetherapy.net).

Despite many years of investment and research, the comparative lack of gene therapies currently available on the market, coupled with the cost of those that are available, are a testament to the challenges still hindering their development and manufacture.

A key challenge still to be overcome is that of ensuring cost-effective manufacture at the necessary speed, scale, and quality for clinical development. Gene therapies which target localized diseases and necessitate only small doses (like Luxterna), involve relatively simple manufacturing processes.

Published results from a successful hemophilia gene therapy trial in 2011 have, however, reinvigorated the gene therapy industry, as well as highlighting the requirement for innovative, scalable technologies which can support the manufacture of gene therapies for systemic diseases which necessitate high treatment doses (Nathwani et al. N Engl J Med 2011; 365:2357-2365).

A look to the future: Transformative solutions to manufacturing challenges

Many gene therapy manufacturers currently rely on the ‘scaling out’ of transient expression platforms. This is resource-intensive and expensive however, due to the significant amounts of GMP-grade plasmid DNA required, and/or the massive cell culture footprint needed by adherent cell cultures.

The future of gene therapy vector production unquestionably lies in stable, scalable manufacturing solutions.

OXGENE™ is a recognized expert in DNA design and engineering, development of cell lines, upstream and downstream processing, and automation. This expertise is leading the transformation of its fully optimized AAV and lentiviral transient expression platforms, moving them towards innovative technologies for scalable and stable manufacturing.

OXGENE is building on strong foundations. Its gene therapy production platforms are based on the proprietary SnapFast™ plasmid technology - modular plasmids that have been designed to function like ‘molecular Lego™’, employing a catalog of characterized DNA elements which can be reliably and easily inserted into specific locations in the plasmid.

OXGENE’s engineered AAV and lentiviral plasmids are able to considerably enhance packaging efficiency and viral titer, while its clonal HEK293 suspension cell line has been specifically chosen for optimal viral vector production.

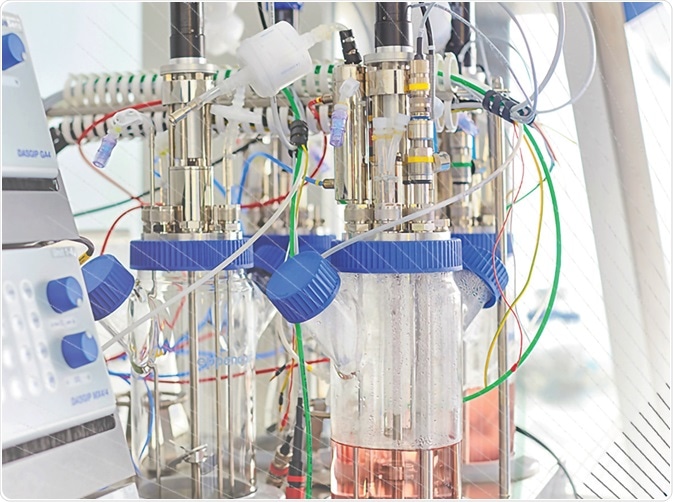

Partnering with OXGENE in the early stages of gene therapy development facilitates the establishment and optimization of transient production, with validated production up to 10 L scale. This process enables straightforward transitioning to a stable technology platform designed for large scale clinical manufacture.

The additional regulatory advantage is gained, as a result of utilizing the same genetic system throughout clinical development. This is because the stable platform maintains the same base cell line and expression cassettes as the transient system.

Producer cell lines are an appealing substitute for transient transfection. Within producer cell lines, all the elements needed for viral vector production, including the transgene of interest, are stably incorporated into the cell’s genome.

Therefore, these need no transfection and a comparatively little manipulation in order to scale up and reliably produce sizable quantities of the viral vector, with reduced batch-to-batch variation and with considerably fewer cost implications.

OXGENE has successfully developed producer cell lines and stable packaging for lentiviral-based gene therapies. A stable lentiviral packaging cell line was generated by transfecting packaging plasmids reconfigured with inducible vsv-g and gag-pol and constitutive rev expression into the HEK293 cell line.

Next, single-cell clones were screened for growth kinetics, as well as stable and inducible expression of viral genes. After numerous rounds of testing and analysis, a single clonal lentiviral packaging cell line was selected to expand, characterize, and optimize further.

Process optimization has improved viral titer more than ten-fold to date. The sheer level of optimization involved in refining OXGENE’s lentiviral packaging cell line makes this an ideal starting point from which to create producer cell lines by stably transfecting a transfer plasmid that contains a self-inactivating lentiviral genome and the transgene of interest.

After a further iteration of the cell line development process, clones which performed the best are expanded further, then transferred for process optimization and scaling up in order to maximize viral titer.

With AAV, however, a different approach was taken. Here, a novel Tetracycline-Enabled Repressible Adenovirus (TERA) system was used as the basis for a stable AAV production platform.

This makes use of an engineered Ad5 adenoviral helper plasmid which includes a switchable negative feedback loop in the viral genome, reducing helper adenovirus contamination to practically zero while increasing AAV yields. This system has also been shown to amplify both AAV rep and cap DNA from the cells’ chromosomes through the use of the well-established AAV Cis-Acting Replication Element (CARE).

This technology enables the stable integration of DNA into cells, as well as its subsequent amplification and concomitant high protein expression levels, which in turn provides a stable, scalable, and adenovirus contaminant-free manufacturing process for AAV.

To summarize, gene therapies are once again set to transform the treatment of some of the world’s most debilitating diseases. While manufacturing challenges have impeded their development and approval, OXGENE has continued to transform gene therapy manufacturing by pioneering the development of tightly controlled, meticulously optimized technologies which facilitate fully scalable, high-quality and cost-effective gene therapy manufacture – meaning that ultimately, gene therapies can be made available to patients who require them.

About OXGENE

OXGENE™ combines precision engineering and breakthrough science with advanced robotics and bioinformatics to accelerate the rational design, discovery and manufacture of cell and gene therapies across three core areas: gene therapy, gene editing and antibody therapeutics.

Gene therapy: We’re transforming the vision of truly scalable gene therapies into a reality; progressing our industry leading transient gene therapy systems towards alternative technologies for scalable, stable manufacturing solutions.

Gene editing: We have automated gene editing to deliver CRISPR engineered cell lines at unparalleled speed, scale and quality and generate complex disease models in mammalian cells.

Antibody therapeutics: We’re employing a novel proprietary mammalian display technology to discover antibodies against previously intractable membrane proteins.

OXGENE™ works at the edge of impossible in mammalian cell engineering. Our scientific expertise and technology solutions address industry bottlenecks. For more information, please visit www.oxgene.com

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.