Pharmacopoeias are assemblages of approved and binding quality regulations that define test requirements and techniques for the analysis of drugs, among other things.

Both the European Pharmacopoeia (Ph. Eur.) and the United States Pharmacopeia (USP) include particular chapters that handle the use of laboratory balances.

The cruciality of weighing samples precisely in pharmaceutical analytical processes has been highlighted in the chapters.

This article aims to present the testing needs for laboratory balances as explained in the appropriate chapters of the pharmacopoeias and the associated certificates provided by the Sartorius Service.

Requirements of the United States Pharmacopeia (USP)

The United States Pharmacopeia Convention is considered a non-governmental scientific organization through which standards for drugs and related products are fixed in the United States.

The United States Pharmacopeia (USP)1 is published on a yearly basis and is known as the official pharmacopeia for the United States of America. It focuses on the use of laboratory balances in two places. Firstly, in Chapter <41> named “Balances”, and then in Chapter <1251> named “Weighing on an Analytical Balance”.

The requisites of Chapter <41> are mandatory for weighing applications where “accurate weighing” is essential. Compliance checks are carried out as part of cGMP audits by the Food and Drug Administration (FDA). Failure to comply will lead to differences in the audit.

Chapter <1251>, at the same time, like all USP chapters from 1000 to 1999, seems to be informal in nature as it provides significant suggestions. But the execution of the recommendations made on the testing and use of balances is optional.

The United States Pharmacopeia: Chapter <41>

Chapter <41> explains particular criteria for all balances utilized for the “accurate sample weighing” of materials. The Chapter’s objective is to guarantee that the error initiated by the weighing application for “accurately weighed” material is decreased to an admissible or insignificant level. This ensures that the impact on the total error remains compliant.

The corresponding chapters on the manufacture of medicinal products or ingredients clearly state if and which substances should be “accurately weighed” within the meaning of the USP and therefore if the corresponding balance should comply with the needs set forth in Chapter <41>.

USP Chapter <41> outlines three particular needs for balances. Firstly, balances must be calibrated over the complete working range. They should fulfill tolerance needs for testing repeatability and precision.

The repeatability test is utilized as a ground for verifying if the “desired smallest net sample weight” could be made within the USP’s tolerance needs.

Calibration

USP Chapter <41> emphasizes that precise weighing of samples must be executed only on balances that are calibrated over the complete working range. But it is not clear how and in which cycles the calibration should be executed.

Sartorius suggests regular calibration in every case, depending on the cruciality of the application (see white paper "Test intervals and tolerances").2 The calibration result must be recorded in a calibration certificate for each case.

Calibration certificates from accredited providers offer the highest possible security, as they have a high level of international recognition and guarantee the traceability of the measurement results to national standards.

Read the following white papers to find out more: “Calibration certificates from accredited suppliers,”3 “The calibration certificate as per the EURAMET cg-18,”4 and “Calibration guideline EURAMET cg-18.”5

Minimum sample weight and repeatability

The requirements of repeatability restrict the weighing range to a usable working range by specifying the lowest sample weight. It is not right to perform weighing below the minimum sample weight.

Execution of repeatability testing is done by weighing a test weight at least ten times. The weight of test weight should be within the working range of the balance, and it does not have to be calibrated as per Chapter <41>.

Repeatability as per USP Chapter <41> also does not necessarily require the use of a small weight as it is presumed that repeatability is independent of the test load utilized. Chapter <41> emphasizes that the test load be within the working range (that is, not below the minimum sample weight).

For practical reasons (as for all repeatability measurements), Sartorius still suggests choosing a one-piece test load, if possible.

In this regard, the needs set out in USP Chapter <41> vary from the recommendation in Chapter <1251>. In this chapter, it is recommended that the size of the test weight for the repeatability test must not surpass a few percent of the weighing range of the balance.

Repeatability is deemed satisfactory if two times the standard deviation of the measured values divided by the smallest net weight to be weighed on the balance (“desired smallest net weight”) is not beyond 0.10%.

The standard deviation leading to the repeatability measurement is thus set in relation to the preferred smallest net sample weight.

If the USP requirement is achieved for the “desired smallest net sample weight”, this guarantees that the USP tolerance need for repeatability is also fulfilled for each initial sample weight above this value, as the relative error turns out to be smaller and smaller as the sample weight increases.

In this context, the general rounding rule of the USP must be noted: The result is first rounded to the number of digits of the acceptance criterion. Having the acceptance criterion of 0.10% specified here, a result of for example. 0.1049% is rounded down to 0.10%, so the repeatability test is thus thought to have been passed in this case.

At the same time, if the result is 0.1050%, the balance has been rounded up to 0.11%, so that in this case the balance does not pass the repeatability test.

Therefore, the repeatability test limits the working range of the balance downwards (see the separate white paper on the subject of the minimum sample weight).6

The smallest possible sample weight available on a balance, or minimum sample weight (M), is 2000 times the standard deviation of the repeatability measurement; it represents the beginning of the working range of the balance.

Therefore, if the standard deviation s is, for instance, s = 0.00015 g, the smallest possible sample weight M is M = 0.3000 g = 300 mg.

USP chapter <41> specifies an additional criterion if a standard deviation s seems to be very small. This pertains to the scale interval (d) of the balance and denotes that if the standard deviation s < 0.41 d, the least load is 2000 × 0.41 d.

Thus, the least sample weight is restricted to the smallest possible value of 820 d. For a four-digit analytical balance with d = 0.0001 g, for instance this implies that the least sample weight could never be below 0.0820 g or 82 mg.

As the repeatability is considerably impacted by the conditions at the place where the balances are installed, the test should be executed at the place of installation and must be checked evenly.

Normally, it is not advisable to alter the “desired smallest sample weight” to the least sample weight value leading to the last repeatability measurement; rather, this must always be specified on the basis of the actual laboratory needs.

Since standard deviation is a statistical quantity and is subject to little variations in each test, setting the “desired smallest sample weight” to the minimum sample weight would imply that the sample weight that can be identified on a balance would change with each test.

For instance, if users achieve the standard deviation of s = 5 μg in a repeatability measurement and fix the least sample weight for their balance to 2000 × s = 10 mg accordingly, they run the risk that in succeeding repeatability measurement where the standard deviation gets altered to, say, s = 8 μg, the minimum sample weight will increase to 2000 × s = 16 mg.

If, following the first measurement, weighing was performed down to the least sample weight; it would be questionable if preceding weights between 10 mg and 16 mg complied with the USP needs.

Thus, it is suggested, as also described in USP Chapter <41>, that the “desired smallest net sample weight” be identified by the user as per the laboratory needs and validated at the time of repeatability testing.

On balances utilized under USP regulations, the validated “minimum desirable net sample weight” must be marked clearly. Some Sartorius balances enable users to enter this in the service menu. Net sample weights below the “minimum desirable net sample weight” are further displayed with a warning symbol.

Furthermore, it must be reiterated here that the mass of the tare vessel is not taken into account for the lowest sample weight. This implies that the lowest sample weight is applicable to the complete weighing range of the balance, irrespective of the tare load.

Therefore, positioning a weighing vessel on the balance precludes weights below the lowest sample weight; instead, the net weight of every sample should be equal to or greater than the minimum sample weight, irrespective of the tare weight.

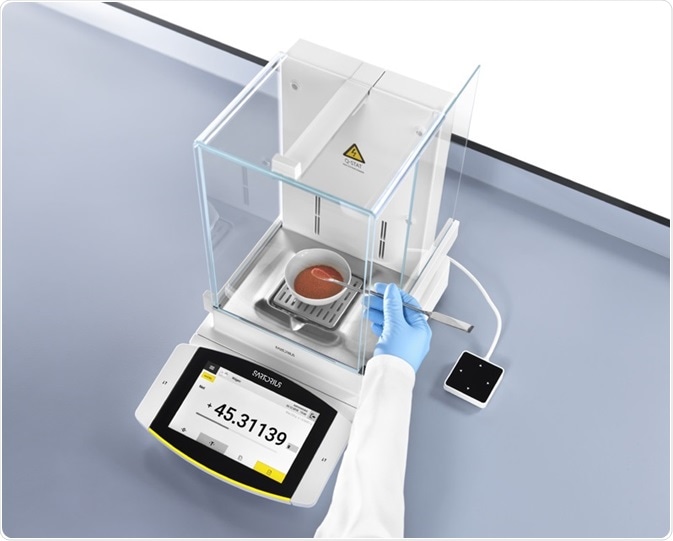

Figure 1. Analytical weighing on a Cubis® II balance. Image Credit: Sartorius Lab Instruments GmbH & Co.KG

To find out more about the requirements of Chapter 2.1.7 of the Ph.Eur. and Sartorius recommendations please download this whitepaper

To find out more about the requirements of Chapter 2.1.7 of the Ph.Eur. and Sartorius recommendations please download this whitepaper

References

- United States Pharmacopeia and National Formulary (USP 43-NF38); 2019.

- Sartorius white paper: Testing intervals and tolerances (how are testing intervals and tolerances defined practically and on the basis of risk), 2021 (planned).

- Sartorius white paper: Calibration certificate from accredited providers (what advantage does our accreditation offer the user), 2021.

- Sartorius white paper: The calibration certificate according to EURAMET cg-18 (understanding calibration certificates and applying results in practice), 2021 (planned).

- Sartorius white paper: Calibration guideline EURAMET cg-18 for electronic, non-automatic balances (specifications, options and implementation of the guideline by Sartorius), 2020

- Sartorius white paper: Lowest sample weight according to USP, OIML R76 and EURAMET cg-18 (how large should the lowest sample be, in order to achieve reliable weighing results?), 2020.

About Sartorius Lab Instruments GmbH & Co. KG

The Sartorius Group is a leading international partner of life science research and the biopharmaceutical industry.

With innovative laboratory instruments and consumables, the Group’s Lab Products & Services Division concentrates on serving the needs of laboratories performing research and quality control at pharma and biopharma companies and those of academic research institutes.

The Bioprocess Solutions Division with its broad product portfolio focusing on single-use solutions helps customers to manufacture biotech medications and vaccines safely and efficiently. The Group has been annually growing by double digits on average and has been regularly expanding its portfolio by acquisitions of complementary technologies.

In fiscal 2021, the company earned sales revenue of some 3.45 billion euros. At the end of 2021, nearly 14,000 people were employed at the Group’s approximately 60 manufacturing and sales sites, serving customers around the globe.

Sponsored Content Policy: News-Medical.net publishes articles and related content that may be derived from sources where we have existing commercial relationships, provided such content adds value to the core editorial ethos of News-Medical.Net which is to educate and inform site visitors interested in medical research, science, medical devices and treatments.