The GFD®Lab is a benchtop Agitated Nutsche Filter Dryer (ANFD) that efficiently performs laboratory solid-liquid separation processes. It is a compact version of a full-scale production filter dryer designed to deliver effective filtration and drying with the reliability and benefits of larger PSL ANFD filter dryers.

This device is engineered to address the common production challenges encountered with traditional methods like Büchner filtration and oven tray-drying. It is ideal for facilitating successful scale-up and scale-down activities and for obtaining predictive performance results.

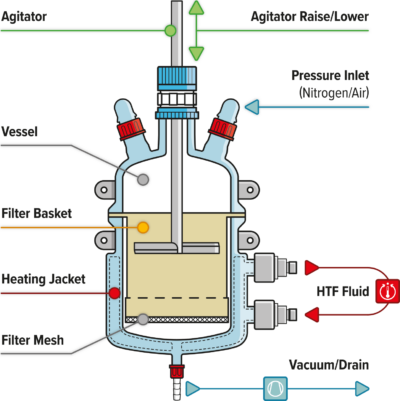

The GFD®Lab features an agitated vessel capable of operating under both vacuum and pressure conditions. Available in glass, stainless steel, or Alloy-22, the vessel includes a heated jacket to enhance drying efficiency. Solid-liquid separation is conducted in a unique filtration basket, which is removable to simplify and maximize product collection.

Widely used by research institutes, laboratories, universities, and companies across various industries, the GFD®Lab nutsche filter dryer supports scientists and process engineers globally in innovating and optimizing their unique processes.

Download the Brochure for More Information

Features and benefits

Combined filtration and drying

Image Credit: Powder Systems

Designed to adhere to Good Laboratory Practices (GLP) for regulated research and development activities, the GFD®Lab is an all-in-one filter dryer. It enables manufacturers and process developers to finish a variety of processes using a single system:

- Slurry Filtration (solid-liquid separation)

- Product Washing

- Re-slurry

- Vacuum Drying

- Product Sampling

- Product Discharge

Unrivalled product recovery

Image Credit: Powder Systems

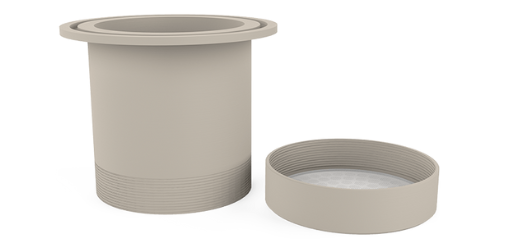

At PSL, the team recognizes the importance of product yield and understands that maximizing it is crucial for maintaining competitiveness in any industry.

The GFD®Lab nutsche filter dryer is designed with features specifically tailored to meet this essential need. Once the processing is complete, the product batch can be easily collected by simply removing the unique filtration basket from the GFD®Lab vessel.

Furthermore, the GFD®Lab basket is engineered to facilitate quick and effortless changeovers of filtration meshes, accommodating various pore sizes and materials such as Polypropylene, PTFE, 316L stainless steel, and Alloy 22. This versatility enables the support of multi-product applications, enhancing both efficiency and adaptability in operations.

Flexible modular design

Image Credit: Powder Systems

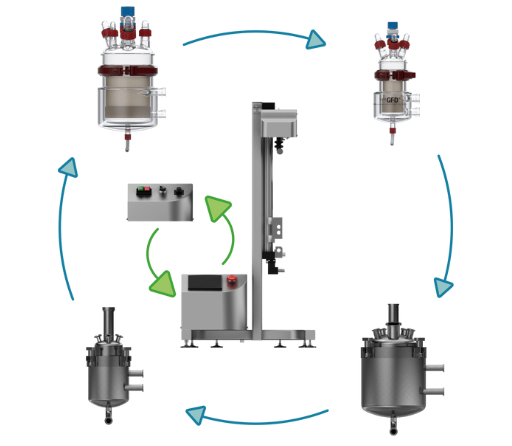

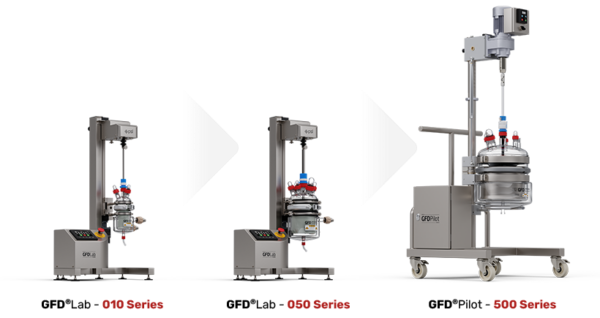

The GFD®Lab is an innovative agitated nutsche filter dryer with a modular design that allows end-users to switch between vessel sizes from the 010 and 050 series without requiring a different base frame.

To increase production flexibility even further, the base frame of each GFD®Lab model is compatible with all available vessel materials, including borosilicate glass, 316L stainless steel, and Alloy 22. This adaptability ensures that the GFD®Lab can meet diverse processing needs across various applications.

Download the Brochure for More Information

GFD®Lab PLUS, the fast-lane to production

Image Credit: Powder Systems

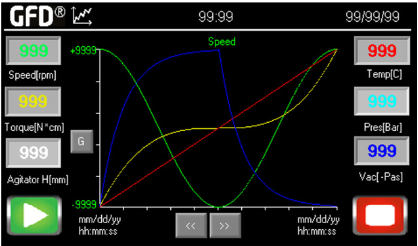

Thanks to its unique modular design, the standard GFD®Lab Filter Dryer can be upgraded to a GFD®Lab PLUS model simply by retrofitting a new base frame to the existing vessel. This upgrade introduces additional features that automate the controls of your GFD®Lab, allowing for accelerated development activities.

- Optimize and save process recipes (up to 99)

- Design process sequences

- Digital display (42-color HMI touchscreen)

- Record and export process data

- Real-time process graph display

- Enhanced user interface allowing quick navigation

Batch reproducibility, at the touch of a button

Image Credit: Powder Systems

The GFD®Lab PLUS enables users to create custom process sequences and fine-tune process recipes to suit specific applications.

Starting production is as simple as pressing a button. Users can initiate pre-designed recipes with their chosen process parameters, such as pressure or vacuum settings, agitator speed and torque, temperature, and duration. This approach not only ensures consistent replication of batches but also minimizes human error.

Predictive scale-up

Image Credit: Powder Systems

Selecting the appropriate process technology during the R&D stage is essential for ensuring successful scale-up. PSL's GFD® Nutsche Filter Dryers are engineered to facilitate the seamless scale-up of development, from early R&D activities with the GFD®Lab to GLP batches and pilot plant production with the GFD®Pilot.

This technology is ideally suited for conducting both scale-up and scale-down studies as it helps maintain your crucial process objectives (e.g., product quality, product yield, batch consistency, etc.) and key production parameters (e.g., filtration time, washing time, drying time, etc.) at every scale.

Be containment-ready with the GFD® Filterbox

Image Credit: Powder Systems

As one of the early pioneers in containment technology, PSL has developed the innovative FilterBox isolator range, designed to accommodate every GFD®Lab vessel size, including the 010, 050, and 500 series.

Choosing a GFD®Lab FilterBox ensures that operators are protected from highly toxic or potent compounds and that your product is safeguarded from the production environment.

Download the Brochure for More Information

Technical overview

Applications and options

Vessel sizes

Source: Powder Systems

| |

GFD®Lab Vessel Sizes |

| |

010 Series |

050 Series |

Typical Product Cake Volume

(process-dependent) |

0.03 – 0.10 L |

0.18 – 0.50 L |

| Vessel Volume |

0.3 L |

2.0 L |

| Filtration Area |

0.002 m2 |

0.010 m2 |

| Frame Dimensions (H x W x D) |

980 x 530 x 330 mm |

980 x 530 x 330 mm |

Upgrade options

Source: Powder Systems

| GFD®Lab Features |

GFD®Lab |

GFD®Lab PLUS |

| Combined Filtration & Drying |

✔ |

✔ |

| Removable Filter Basket |

✔ |

✔ |

| 316L or Alloy 22 Vessel |

✔ |

✔ |

| Agitator Raise & Lower (R&L) |

Manual R&L only |

Automated R&L available |

| Digital Display & Touchscreen |

✘ |

✔ |

| Real-time Value & Graph Display |

✘ |

✔ |

| Process Sequence Design |

✘ |

✔ |

| Process Recipe Optimization |

✘ |

✔ |

| Process Data Recording & Exporting |

✘ |

✔ |