Powder Systems Limited's (PSL) technology supports hundreds of pilot and production facilities worldwide every day, enabling them to manufacture and market their products more rapidly. PSL Agitated Nutsche Filter Dryers (ANFD) are utilized across various industries, including pharmaceuticals, fine chemicals, and precious metals.

PSL's ANFD Filter Dryer production systems are engineered to effectively wash and isolate solids during complex chemical synthesis processes and in challenging production environments. These solutions are designed to address common issues faced by manufacturers using traditional production methods like Büchner filtration and oven tray-drying.

Each filter dryer features an agitated vessel that operates under both vacuum and pressure conditions. The vessel is available in stainless steel or alloy 22 and can be coated with materials like PFA (perfluoroalkoxy alkane), ensuring durability. Additionally, it includes a heated jacket and agitator to promote efficient drying and thorough mixing of products.

Download the Brochure for More Information

Features and benefits

Combined filtration and drying

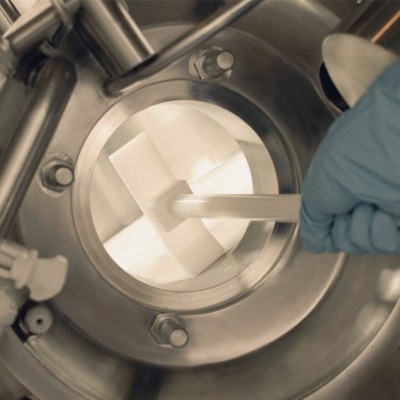

PSL's Agitated Nutsche Filter Dryers are multifunctional equipment designed to meet Good Manufacturing Practices (GMP) standards for regulated development and production activities. These systems enable process developers and manufacturers to consolidate a variety of processes into a single system.

- Slurry Filtration

- Product Washing

- Re-slurry

- Vacuum Drying

- Product Sampling

- Product Discharge

CGMP compliance, delivered

Image Credit: Powder Systems

PSL's expertise is rooted in a thorough understanding of GMP regulations, bolstered by practical experience across diverse manufacturing workflows.

Its filter dryers are engineered to deliver maximum safety and quality and can be tailored to meet various industry standards (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.), and initiatives (PAT, etc.) set by industry regulators, including the FDA.

Be containment-ready

Image Credit: Powder Systems

Over the past thirty years, PSL has built a reputation among industry partners for providing precision-engineered containment solutions that safeguard workforce health.

Many industrial filtration and drying processes require the integration of containment technology to protect operators from highly toxic compounds and/or to shield sensitive products from adverse production environments.

PSL's high containment systems ensure operator safety and operate under a negative pressure, HEPA-filtered atmosphere. Globally, PSL isolators have been employed to handle highly potent compounds with extremely low Occupational Exposure Limits (OEL), such as 20ng/m3. These compounds often include High Potency Active Pharmaceutical Ingredients (HPAPI), cytotoxic substances, and other hazardous materials.

PSL's containment solutions are customizable to meet the specific needs of each company, offering both rigid and flexible/disposable options.

Additionally, PSL gloveboxes are manufactured to comply with various industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.), and initiatives (PAT, etc.).

Download the Brochure for More Information

Predictive scale-up

Image Credit: Powder Systems

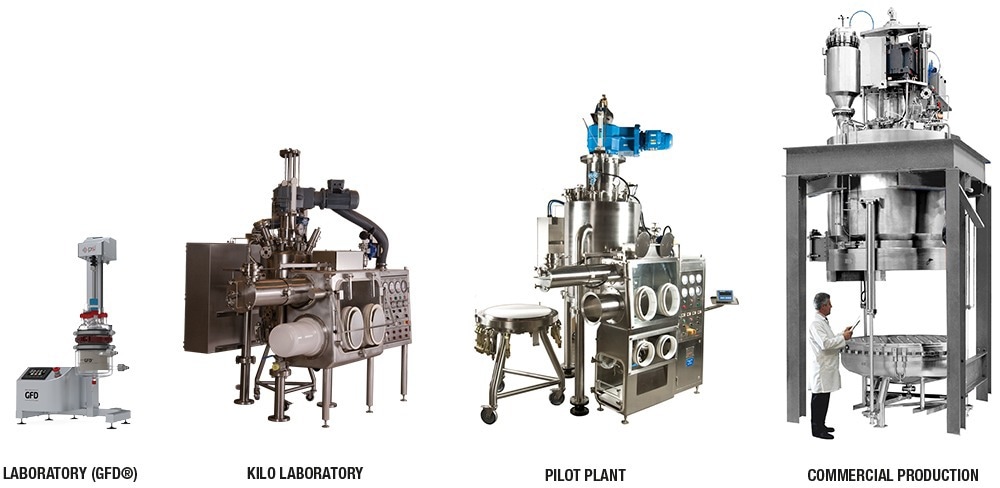

Powder Systems understands that selecting the right processing technology is critical when it comes to scaling up processes and ensuring ultimate production success.

PSL's well-established range of filtration and drying solutions is internationally acclaimed for optimizing complex scale-up processes, from initial R&D phases to GLP batches, through to pilot plants and ultimately, GMP commercial production.

Its extensive filter-dryer portfolio allows users to conduct both scale-up and scale-down studies while consistently meeting diverse process goals (such as product quality, yield, and batch consistency) and managing production parameters (such as filtration time, washing time, and drying time) across all scales

Maximizing competitiveness

Image Credit: Powder Systems

Download the Brochure for More Information

PSL recognizes the value of the product and how important it is for users to maximize production yield to maintain market competitiveness. This essential requirement was taken into consideration when designing the core features of filter-dryers.

After completing the process of using a PSL nutsche filter dryer, users can easily recover their valuable product by using the PSL agitator to automate the discharge process. Following this, the remaining batch—often referred to as the product heel—can be collected using the "Direct Heel Recovery" method, which PSL originally developed and has been a standard in the industry for several decades.

This method is highly effective for achieving high-yield productivity and involves manually raking the product heel into a PSL high containment off-loading glovebox. This glovebox, which is ergonomically designed and integrated by PSL, ensures comprehensive product recovery while maintaining safety for operators, the product, and the environment.

Technical overview

Applications and options

Vessel sizes

Source: Powder Systems

| Filtration Area |

0.05 m2 |

0.125 m2 |

0.3 m2 |

0.6 m2 |

1.0 m2 |

| Filter Cake Volume Range |

1 to 10 L |

2.5 to 50 L |

6 to 120 L |

12 to 240 L |

50 to 400 L |

| Filter Cake Height Range |

20 to 150 mm |

20 to 200 mm |

20 to 400 mm |

20 to 400 mm |

50 to 400 mm |

| Max Liquid Volume |

20 L |

100 L |

270 L |

600 L |

1000 L |

Industry applications

Source: Powder Systems

| Industries |

Production Scale |

Processes |

Product Form |

Ingredients |

| Pharmaceuticals |

Process optimization |

Filtration |

Suspension |

API drugs |

| Chemicals |

Pilot development |

Separation |

Slurry |

Intermediates |

| Food |

Pre-clinical & clinical |

De-watering |

Wet cake |

Raw materials |

| Material sciences |

GMP batch |

Re-slurry |

Powder |

Excipients |

| Synthesis |

Commercial production |

Washing |

Semi-solids |

Reagents |

| Special processes |

|

Mixing |

|

Catalysts |

| |

|

Sampling |

|

Precious metals |

| |

|

Drying |

|

Graphene, Lithium |

| |

|

Discharge |

|

|