High throughput (HT) gene-to-antibody manufacturing is the most economical choice for small-scale recombinant antibodies. Small-scale projects can be finished in as little as 10 business days with the help of GenScript’s high throughput gene synthesis platform and unique TurboCHO™ transient expression technology.

Small-scale projects begin with customer-supplied sequences and end with purified products.

A vast capacity of 10,000+ targets/month makes it possible to hasten medicines' development and global commercialization. Various purified antibody products, including IgGs, Fab, scFv, VHH, bi-specific antibodies, and more, can be delivered in large quantities (i.e., from ug to mg) using the TurboCHO™ High Throughput platform.

The automated technology assisting the TurboCHO™ High Throughput platform eliminates lot-to-lot variation and guarantees a high expression level.

Image Credit: GenScript

Highlights

- Availability of multiple isotypes

- Large capacity

- Fast delivery in 2 weeks

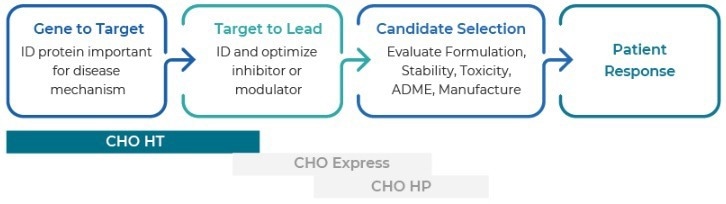

General workflow

Image Credit: GenScript

Service specifications

Source: GenScript

| Perspective |

Description |

| Targeting Amount (mAb) |

- 0.1 - 5 mg

- Other amounts upon request

|

| Turnaround Time |

As short as 2 weeks |

| Target Types |

- Recombinant proteins

- Antibody formats including full-length antibody, Fabs, scFvs, VHHs, or other fragments fused with Fc

|

| QC |

- SDS-PAGE

- Endotoxin control

- LC-MS

- Additional QC options available upon request with charge

|

| Purification |

- 1-step purification (Protein A for antibody targets)

- Additional purification options available upon request with charge

|

| Additional Services |

ELISA, Cell-based assay, FACS screening, Octet® BLI assay, Biacore™ SPR assay, etc. |

Note:

1. A minimum sample size of 8 is typically needed.

2. 5% of the samples will be chosen randomly for the LC-MS and endotoxin test.

Case studies

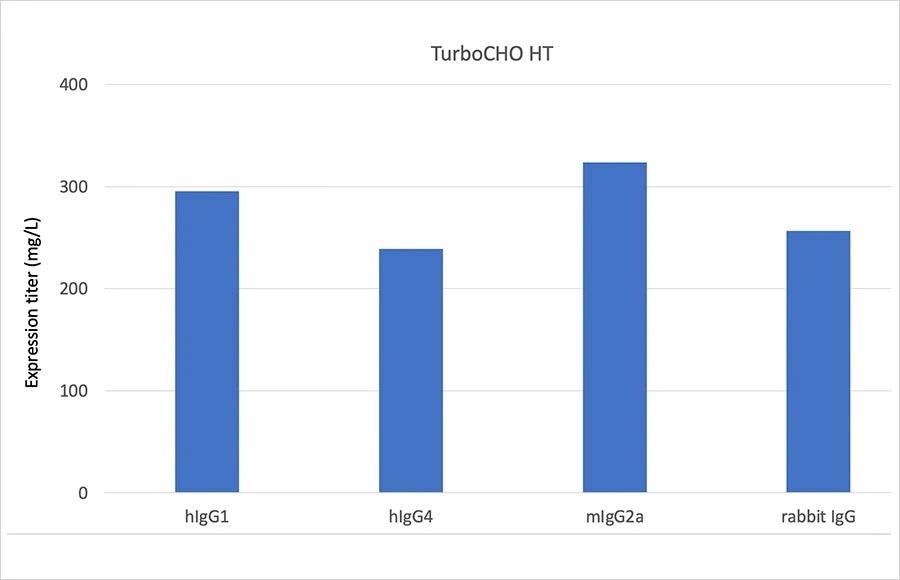

High expression titers in multiple isotypes

Image Credit: GenScript

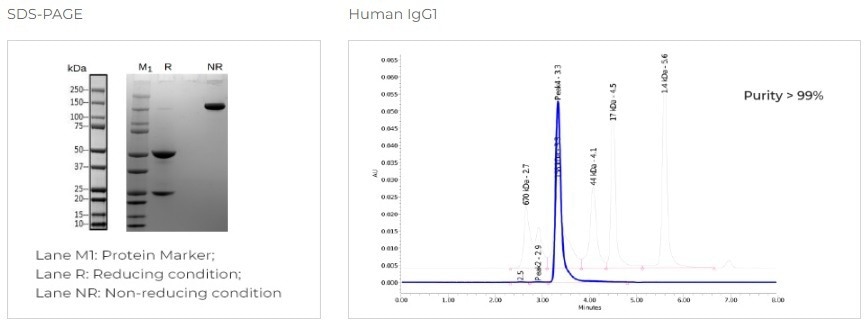

High-purity of antibodies expressed in TurboCHO™ high throughput system

Image Credit: GenScript