For laboratories involved in culture media preparation, sterile dispensing is essential for successful downstream applications and to meet quality requirements. Furthermore, as a growing need for cost saving and performance improvements exists, a reliable work flow is necessary.

These requirements have created a strong demand for an automated medium dispensing system that allows reliable walkaway operation and at the same time fulfils quality requirements. MEDIAJET has been developed to meet these needs.

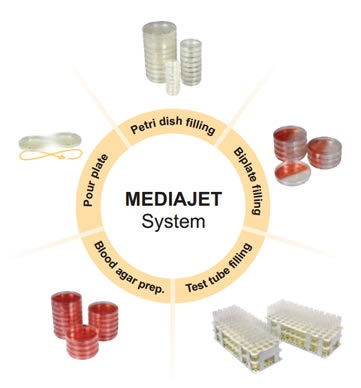

The MEDIAJET system offers the unique flexibility to fill Petri dishes of various sizes, Petri dishes with two compartments as well as test tubes of various diameters and length. At the same time, MEDIAJET requires only minimal bench space in the laboratory. MEDIAJET is the perfect complementation to the INTEGRA MEDIACLAVE media preparator range as it allows the continuous filling of up to thirty litres media into Petri dishes.

Features

Easy handling - The intuitive user interface makes it very easy to control all functions of MEDIAJET. The operation of the system is entirely self-explanatory, as all functions and prompts are explained in plaintext.

Media cost reduction - MEDIAJET has a built-in "Agar Spread Function" which ensures a homogenous distribution and an even surface of the agar. It helps to optimize the Agar level in the Petri dish and thereby allows a significant reduction of media costs.

Reliable walk-away automation - With the novel Feed-In/ Stack-Out technology, MEDIAJET guarantees a reliable operation. Typical production variations in the diameter or shape of the Petri dishes are easily handled by the unit, as they are actively guided throughout the entire filling process. The optical dish sensors of MEDIAJET can be easily adjusted to virtually every Petri dish brand at the user interface level.

Eliminating sources of contamination - For consistent Agar plate quality, a clean environment is essential. The surface of the filling chamber is manufactured of a single piece of resistant PE, which allows efficient cleaning. In addition, MEDIAJET is equipped with a UV lamp extending over the full length of the rotor where the dishes are opened during the filling process. The lamp emits powerful 2.1 W UV-C radiation for optimal bactericidal activity in the area most vulnerable to contamination.

Applications

MEDIAJET vario allows the filling of Ø 90, Ø 60 or Ø 35 mm dishes by using the corresponding conversion set.

In just a few minutes, MEDIAJET vario base unit can be converted and adjusted to fill the Petri dishes of choice, providing invaluable flexibility to your media preparation lab.

Operation

MEDIAJET is easily set up and quickly ready for use. Load the carrousel with up to 540 Petri dishes, connect the MEDIAJET to your sterilised culture medium source and start the automated dispensing at the touch of a button.

Up to 19 individual Petri dish filling programs with user-defined parameter settings such as dish height, dispensing volume or number of dishes can be saved and recalled. Different operation modes for Petri dish filling can be executed and the parameters set to your needs:

- STANDARD mode: Is used for the standard filling of Ø 90, 60 or 35 mm Petri dishes

- TURBO mode: Is used to accelerate the filling process. Together with the optional turbo mode kit installed, up to 1'100 Petri dishes can be filled in one hour.

- POUR PLATE mode: Total viable count determination is mainly carried out by using the pour plate method. However, pouring the plates by hand is time-consuming and laborious. The POUR PLATE mode facilitates this process by automatically shaking the Petri dishes. Depending on the volume or viscosity of the medium to be filled into Petri dishes, different shaking levels are selectable according to requirements.

- BATCH mode: The Batch mode can be used for applications where it is important to have a highly planar agar surface, as for example automatic colony counting.